Is Geothermal Energy Easy To Make?

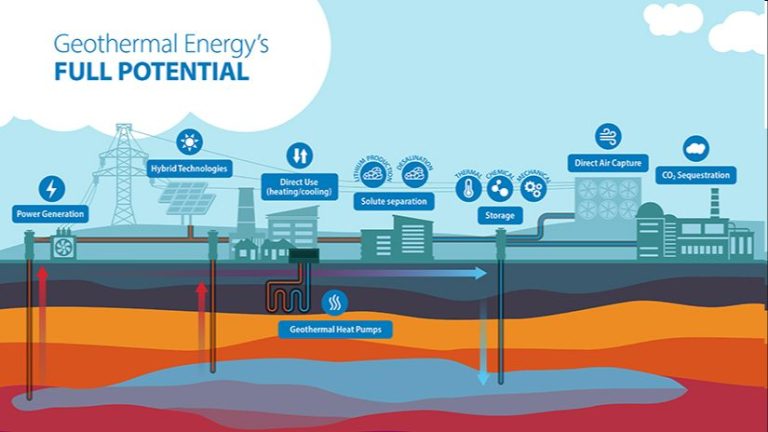

Geothermal energy is a renewable energy source that utilizes heat from the Earth’s interior to produce electricity and provide heating. There is debate around how easy geothermal energy is to produce and utilize on a large scale. While geothermal energy itself is abundant, actually capturing and harnessing it for practical use can be challenging and expensive in many cases.

This article will provide an overview of geothermal energy and the key components involved in geothermal power generation. It will examine the accessibility of geothermal resources, the difficulties around drilling and power plant construction, ongoing maintenance requirements, environmental considerations, costs, and other factors that determine how easy it is to harness geothermal energy. The goal is to provide a thorough look at the geothermal energy production process and the feasibility of scaling it up globally.

What is Geothermal Energy?

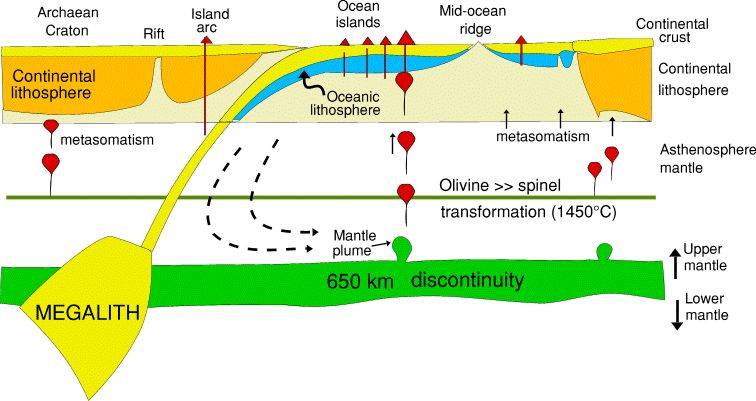

Geothermal energy is heat energy generated and stored in the Earth. It originates from the original formation of the planet, the radioactive decay of minerals, and ongoing heat loss from the earth’s core. This heat is conducted to areas near the surface and can emerge naturally in the form of hot springs, geysers, and volcanoes. It can also be brought to the surface artificially by drilling water or steam wells. Once accessed, geothermal energy can be used directly for heating or to generate clean electricity.

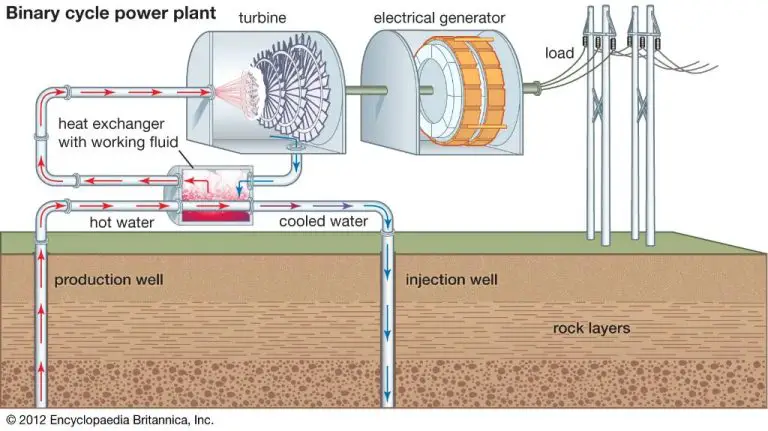

To generate electricity from geothermal energy, wells are drilled into underground reservoirs to provide a supply of hot water or steam. This geothermal fluid is piped up to power plant facilities where it turns turbines connected to electricity generators. The used geothermal fluid is then returned down an injection well into the reservoir to be reheated, continuing the cycle. Geothermal power plants operate continuously, harnessing the earth’s consistent internal temperature to provide a stable and renewable energy source.

Geothermal Power Plant Components

Geothermal power plants require several key components to generate electricity from geothermal reservoirs under the earth’s surface. Here are the main parts of a geothermal power plant:

Production Wells – These are deep wells drilled into a geothermal reservoir to provide a steady stream of hot water and steam to the surface. The wells can be over a mile deep and are reinforced with steel casings and cemented into place.

Pipelines – Pipes carry the geothermal fluid from the production wells to the power plant. These are usually made from steel and well insulated to prevent heat loss.

Separators – These separate water and steam after extraction. The steam will be used to turn the turbine generators.

Turbine Generators – The geothermal steam is used to spin turbine blades connected to electricity generators. This converts the earth’s heat into electrical power.

Condensers – These cool the geothermal fluid after it leaves the turbines and condenses it back into water, which can be pumped back into the reservoir.

Cooling Towers – Excess heat from the condenser is released into the air via cooling towers.

Transmission Lines – Electrical power generated is transferred via transmission lines to homes, businesses and utilities.

The main components of a geothermal power plant work together to harness the earth’s internal heat and convert it into clean, renewable electricity. Proper drilling, construction and maintenance are needed to operate these plants successfully.

Accessibility of Geothermal Resources

Not all locations have accessible geothermal resources suitable for energy production. Geothermal plants rely on places with optimal conditions – namely sufficient subsurface heat and abundant water resources. These geothermal reservoirs allow water to be heated to steam to spin electricity-generating turbines. Unfortunately, these conditions only exist in specific geographic regions, limiting where geothermal plants can be built.

Regions like western North America, Indonesia, Philippines, Iceland and parts of Africa and South America have good access to viable geothermal reservoirs closer to the Earth’s crust surface. However, large portions of the world lack these necessary geothermal resources at economical drilling depths. For example, areas with thick insulating sedimentary rock layers require deeper wells to reach hotter rock. Drilling thousands of meters into hard crystalline basement rock becomes challenging and expensive.

Additionally, geothermal reservoirs need water and permeable rock available to transport heated fluids to the surface production wells. Low permeability regions prevent efficient water circulation, even if heat sources exist at depth. Areas with insufficient underground aquifers also struggle to support geothermal production. This water accessibility affects potential plant generating capacity.

These geographic limitations restrict global deployment of geothermal energy. While excellent potential exists in volcanic areas closer to plate boundaries,plants cannot be easily built everywhere. Companies must thoroughly assess quality reservoirs before undertaking major drilling projects and power plant construction.

Drilling Challenges

Drilling geothermal wells can be expensive and risky. Geothermal reservoirs are often located deep underground, sometimes miles below the surface. Drilling to these depths requires advanced drilling technology and expertise.

There are several technical challenges involved in geothermal drilling:

- Extremely high temperatures – As drills go deeper into the earth, they encounter higher temperatures which can damage equipment.

- Unknown geology – Drillers may unexpectedly hit hard rock formations that are difficult to penetrate.

- Corrosive fluids – Geothermal reservoirs contain hot corrosive fluids that can degrade drilling equipment.

- Lost equipment – Tools and equipment can get lodged or lost in complex underground fracture networks.

These issues make geothermal drilling an expensive endeavor, with a single well often costing millions of dollars to develop. Additionally, despite advanced technology, there is still a risk that some geothermal wells turn out to be non-productive if adequate heat and fluids are not found.

Power Plant Construction

Building the geothermal power plant has large upfront capital costs and complex engineering. Constructing the plant requires specialized equipment and expertise to handle the high temperature drilling and piping. Geothermal fluid can reach over 700 degrees Fahrenheit, requiring steel piping that can withstand the aggressive chemistry. Managing the geothermal source also involves injecting spent geothermal fluid back underground to maintain reservoir pressure and sustainability.

The power plant itself needs heat exchangers, turbines, generators, and cooling towers designed specifically for geothermal applications. The rotating equipment must withstand high vibration and thermal stresses over decades of operation. Materials selection, corrosion protection, and leak detection are vital engineering considerations. Proper instrumentation and control systems are also key to smooth plant operation.

In addition to the technical challenges, constructing a geothermal power plant in remote locations near the resource adds logistical complexity. Roads, infrastructure, and supporting facilities may need to be built before the plant itself. Permitting and regulatory requirements must also be satisfied.

While geothermal power offers environmental benefits, the plant construction involves substantial capital costs and engineering expertise to overcome the difficulties of harnessing the earth’s heat for electricity generation.

Ongoing Maintenance

Geothermal power plants require regular maintenance and monitoring to sustain production over time. As geothermal fluid is extracted from underground reservoirs, pressure and temperature can decline. This reduces a plant’s output capacity.

To counteract declining output, geothermal operators often drill make-up wells. These injection wells route spent geothermal fluid back underground to recharge the reservoir. Maintaining reservoir pressure sustains production rates.

Geothermal sites also monitor fluid chemistry. The mineral content of extracted geothermal fluid can form scale deposits on equipment over time. Chemical treatment helps reduce scaling and corrosion issues.

In addition, technicians perform routine maintenance on turbines, pumps, heat exchangers and other infrastructure. This involves inspections, testing, repairs and parts replacement when needed.

While geothermal power plants have higher uptime than some renewable sources, ongoing monitoring and maintenance is crucial for sustaining long-term operation.

Environmental Considerations

While geothermal energy is considered a clean and renewable energy source, there are certain potential environmental concerns to be aware of.

Geothermal power plants emit much lower greenhouse gases than fossil fuel plants. However, geothermal sites do release carbon dioxide and some sulfur dioxide and hydrogen sulfide emissions from underground reservoirs. The amounts are far below levels considered harmful, but facilities need to manage and monitor emissions.

There could also be impacts on land stability in terms of subsidence or small-scale induced earthquakes from water injection drilling. Proper construction techniques minimize this risk, but sites must monitor for any land disturbances.

There is also concern over proper fluid disposal and contamination of local water sources from geothermal operations. This can be mitigated through liquid disposal via reinjection wells and protecting aquifers from operations waste.

Lastly, development of geothermal plants and wells can disrupt local wildlife habitats and vegetation during construction. Sites should aim to limit surface disturbances and restore ecosystems after completion.

With proper siting, development, operation procedures, and monitoring, the environmental impact of geothermal plants can be effectively minimized while providing the benefits of clean renewable energy.

Cost Analysis

Geothermal energy is competitively priced compared to conventional energy sources like coal and natural gas. The levelized cost of electricity (LCOE) for geothermal power, including capital and operating costs over a power plant’s lifetime, ranges from 4-7 cents per kilowatt hour (kWh). This is in line with natural gas power which averages around 5-7 cents/kWh, and cheaper than coal which averages closer to 8-11 cents/kWh.

However, the upfront capital costs for geothermal plants are considerable. Drilling exploratory wells and constructing a geothermal power plant costs between $3-6 million per megawatt, higher than coal ($2-3 million per MW) but similar to nuclear power’s $4-8 million per MW price tag. As such, financing and risk assessment are major factors when planning geothermal projects.

Once a geothermal power plant is constructed, the operating and maintenance costs are very low compared to other energy sources. Fuel is free, plants run 24/7 with 95% uptime availability, and have a long lifespan of 20-30 years. Low ongoing costs make geothermal an attractive investment. Decommissioning costs may also be high due to well sealing and site remediation needs.

Ultimately, access to a viable geothermal resource is key when considering cost factors. With a good site and suitable hot rocks, geothermal power delivers cheap, clean electricity for decades.

Conclusion

To summarize, producing geothermal energy has both easy and challenging aspects. On the one hand, once set up, geothermal plants provide consistent renewable power without needing any further fuel input. The geothermal resource itself is free and continuously available.

However, initial access and construction of geothermal facilities requires advanced drilling technology to reach underground heat reservoirs. Building the above-ground power plant is also complex and costly. Careful feasibility studies are necessary to locate optimal sites. Maintenance can be intensive for components exposed to harsh geothermal conditions.

Overall, while geothermal energy harnessing the Earth’s internal heat offers environmental benefits, actually developing these facilities demands substantial expertise and investment. But for suitable locations, geothermal presents a sustainable alternative to meet local energy needs. With improved technologies, this renewable resource could play an increasing role in our energy mix.