How Much Is A Solar Cell?

Solar cells, also called photovoltaic cells, are electrical devices that convert sunlight directly into electricity using the photovoltaic effect. When light shines on a solar cell, photons from the sunlight are absorbed by the cell, causing electrons to be freed from the atoms in the cell. These freed electrons can then flow as an electric current when the solar cell is connected in an electrical circuit.

The main purpose and application of solar cells is to generate clean, renewable electricity from sunlight. Solar cells have many uses, including powering calculators and watches, charging mobile phones and batteries for backup power, providing electricity to homes and businesses via rooftop solar panels, and generating utility-scale solar power by arranging many solar panels together in large arrays.

Types of Solar Cells

The most common types of solar cells are silicon cells and thin-film cells. Silicon cells are made from silicon semiconductors and are classified as either monocrystalline silicon or polycrystalline silicon. Monocrystalline silicon is composed of a single crystal lattice, making it highly efficient but more expensive to produce. Polycrystalline silicon contains multiple crystal lattices and is cheaper to manufacture but slightly less efficient 1. Thin-film solar cells are made by depositing one or more thin layers of photovoltaic material, like amorphous silicon or cadmium telluride, onto a substrate. They are less efficient than crystalline silicon cells but have the advantage of being thinner, flexible, and cheaper to manufacture 2. Key differences between silicon and thin-film solar cells include efficiency ratings, costs, appearance, weight, toxicity, and performance in low light or high temperatures.

Manufacturing Process

The most common type of solar cell is made from silicon. Here are the basic steps to manufacture a silicon solar cell:

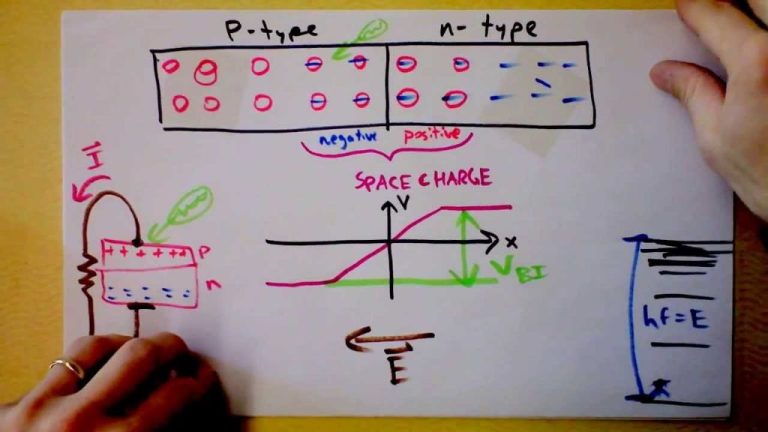

Silicon is extracted from sand and purified into a crystalline form. This silicon is then cut into thin wafers using wire saws or lasers [1]. These wafers act as the base for the solar cells.

The silicon wafers are then treated with chemicals, producing an n-type and p-type semiconductor material. When these two materials are joined, an electric field is created [2].

Conductive contacts are screen printed onto the top and bottom of the wafer to allow electrical current to flow. An anti-reflective coating is applied to the top to help absorb more sunlight.

The individual cells are electrically tested, sorted, and assembled into panels by wiring them together.

The key steps are thus purification, cutting, doping, adding contacts, testing, and panel assembly to create a working silicon solar cell.

Cost Breakdown

The manufacturing cost of solar cells can be broken down into several key components:

Materials – This includes the cost of silicon, glass, encapsulant materials, backsheets, junction boxes, and other raw materials. Silicon accounts for the largest share, making up around 45-55% of total solar cell costs. Polysilicon prices have declined dramatically in recent years due to oversupply.1

Labor – Labor costs account for around 15-25% of the total manufacturing cost. The average labor cost per hour for solar cell production in the U.S. is $25-31 USD.2 Automation can help reduce labor costs over time.

Equipment – The cost of manufacturing equipment like crystal growers, wafer saws, diffusion furnaces, screen printers, and testers represents around 10-15% of total costs. New equipment investments are required over time as technology improves.

Other costs include factory overheads, sales, general and administrative expenses. Large manufacturers are able to benefit from significant economies of scale and cost advantages.

Economies of Scale

One of the main factors that affects the cost of solar panels is economies of scale. As production volumes increase, manufacturers are able to achieve lower costs per panel produced. There are a few key reasons for this:

First, as production increases, fixed costs like R&D, equipment, and facilities can be spread across a larger number of units, reducing the per unit fixed cost (Source). With solar panels, many of the raw materials and production processes benefit from economies of scale. As volume increases, panel makers can negotiate lower prices on polysilicon, glass, and other components.

Higher production volumes also allow manufacturing efficiencies to be realized. Workers gain expertise and improve productivity through repetition and experience. Production lines and processes can be streamlined and optimized (Source). These learning curve effects have played a major role in lowering solar panel costs over time.

In summary, by producing at larger scales, solar panel manufacturers have been able to drive down costs through spreading fixed costs, bulk discounts on materials, and manufacturing efficiencies.

Non-Material Costs

Non-material costs, also known as “soft costs”, make up a significant portion of the total expense for a residential solar system. These costs include permitting, installation labor, customer acquisition, financing, inspection, land acquisition, and other costs not associated directly with solar panel hardware.

Permitting costs include application fees, design reviews, and inspections required by local authorities to install a solar system. According to the U.S. Department of Energy, permitting, inspection and interconnection costs make up an average of $400-$900 for a residential solar system, but this can vary significantly by location (Solar Soft Costs Basics). Streamlining the permitting process could reduce overall costs.

Installation labor accounts for up to 20% of the total cost. Roof-mounted systems require more labor for mounting and wiring than ground-mounted systems (Solar Soft Costs). Hiring experienced installers is key to minimizing installation costs.

Land acquisition costs only apply for ground-mounted systems, which require adequate unshaded space. This can become a significant expense in densely populated areas with high real estate prices. Roof-mounted systems avoid land costs but have size limitations.

System Costs

In addition to the solar panels themselves, there are other system costs that factor into the total price of a solar installation. These include the inverter, wiring, labor, permits and taxes.

Inverters are a critical component that convert the DC electricity generated by solar panels into usable AC electricity for your home. According to Solar.com, inverters typically cost $0.20 to $0.40 per watt. So for a 5 kW system, the inverter may cost $1,000 to $2,000.

Wiring and electrical components like junction boxes and disconnects are needed to connect the solar array to your electrical panel and the utility grid. This can cost around $1,000 for a typical residential solar installation.

Labor is a significant portion of the system cost, often accounting for up to 20% of the total according to Angi. For a 5 kW system, labor may cost between $2,000 – $5,000 depending on system complexity and location.

Permits, inspection fees and sales tax can add several hundred to a couple thousand dollars depending on your jurisdiction. These costs pay for building permits, grid connection approval and taxes on solar equipment.

Recent Pricing Trends

Solar cell and module prices have been on a steady downward trend over the past decade. According to PV Magazine, solar cell prices hit an all-time low in November 2022, with mono perc cells priced at $0.0603 per watt. This represents a significant drop compared to pricing just a few years earlier. In September 2022, PV Magazine reported that solar module prices across all categories had declined by around 10% on average, with no expectation of prices stabilizing. The continued technology improvements and economies of scale in solar manufacturing are allowing prices to decrease at a rapid pace. Industry experts predict this trend will continue, with solar energy becoming increasingly cost competitive compared to fossil fuel energy sources.

Factors Influencing Cost

There are several key factors that influence the cost of solar cells and solar panel installations. Government policies like tax credits and incentives can significantly reduce costs for consumers. For example, the federal solar tax credit in the U.S. allows homeowners to deduct 26% of the cost of installing a solar energy system from their taxes through 2022, which provides major savings.

Global supply and demand also impacts pricing. As solar energy becomes more popular worldwide, increased demand can sometimes outpace supply of solar panels, causing prices to rise. However, as more solar panel manufacturers scale production, prices typically fall again. Technological advancements that improve solar cell efficiency or lower production costs get passed down to the consumer as well. For instance, improvements in silicon purification and automation have reduced solar cell costs over time.

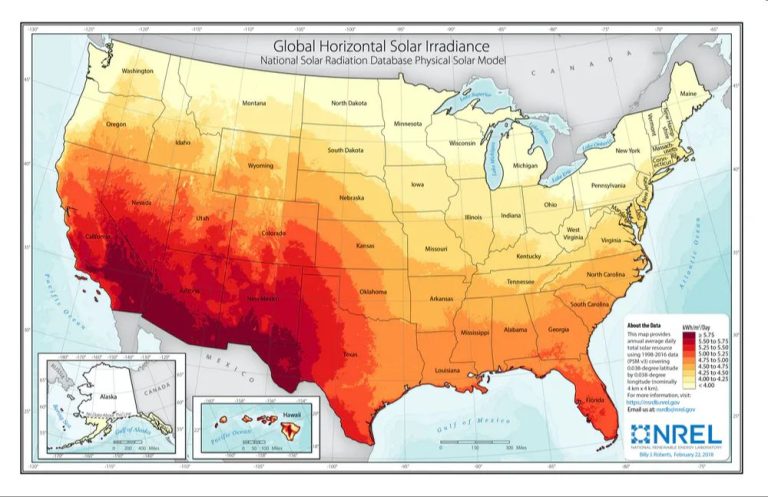

Some additional influences on cost include system size, location, electricity rates, and financing options. Larger solar installations benefit from economies of scale. Areas with high electricity costs or frequent power outages make solar more cost-effective. And secured low-interest solar loans spread out system costs over time.

Conclusion

In summary, the cost of solar cells has declined substantially over the past decade, driven by improvements in manufacturing, economies of scale, and technology advances. Today’s prices are about 1/4 of what they were just 10 years ago. Further cost reductions are expected, with some projections estimating solar at $0.02/kWh by 2030. Key factors that will continue to drive down costs include improving panel efficiency, streamlining supply chains and installation, and ongoing policy support. The future of solar is bright, with costs becoming ever more competitive with fossil fuels. Widespread adoption of this clean, renewable energy source is critical for transitioning away from coal, oil and natural gas. With continued innovation and economies of scale, solar has potential to transform our energy infrastructure and offer an affordable, sustainable power source across the globe.