How Much Does It Cost To Set Up Geothermal Energy?

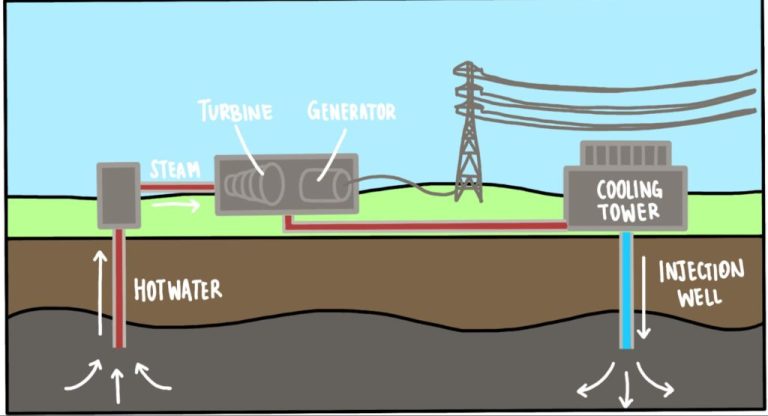

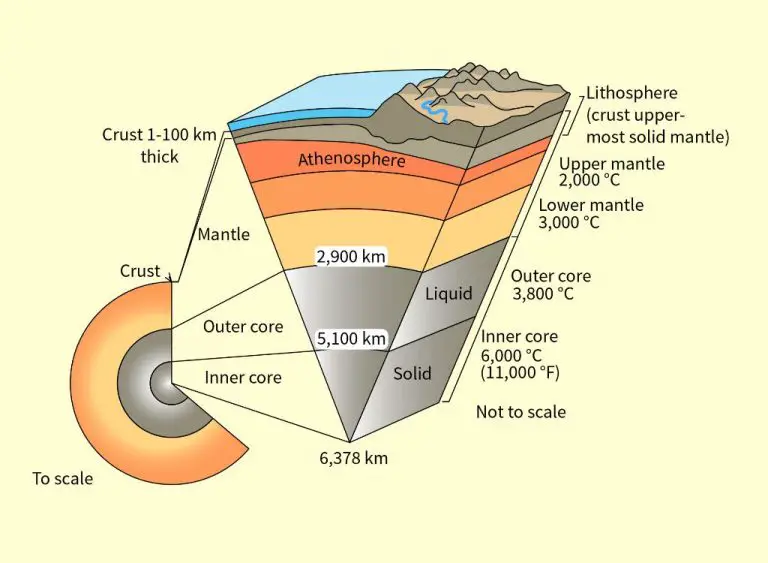

Geothermal energy is thermal energy generated and stored in the Earth. It is a renewable energy source that utilizes the natural heat within the earth’s crust to produce energy for heating and cooling homes as well as generating electricity.

There are a variety of costs involved in setting up a geothermal energy system. The main expenses include drilling costs for installing the underground loops, resource exploration and site preparation, power plant construction for electricity generation, piping to connect the system, maintenance, and financing costs. Total costs can range widely based on the site location and size of the system.

Some of the key factors that impact the overall costs include type of system being installed (direct use vs electricity generation), well depth required, soil/rock type, availability of subsurface water, and heating/cooling needs. Tax incentives and credits may help reduce the net costs. This article will provide an overview of the various costs involved and typical price ranges for residential and commercial geothermal energy systems.

Drilling Costs

The cost of drilling the wells for a geothermal system can range greatly depending on several factors such as the drilling depth, drilling method used, and the location’s terrain. Geothermal wells are typically drilled to depths of 300 feet or more depending on the underground temperature at that depth. Drilling deeper wells into hotter temperatures increases system efficiency but also costs more with reports showing drilling costs averaging $20-30 per foot.

Vertical drilling is the most common and cost effective method but horizontal and directional drilling may be utilized if needed to avoid obstacles or reach optimal resources. Drilling also costs more in hard rock compared to sedimentary soil. National averages for geothermal well drilling range from $15,000 to $30,000 according to industry sources, with higher costs on the coasts and lower costs in the middle of the country.

Resource Exploration

Resource exploration is a key cost component when developing a geothermal power plant. This phase involves identifying potential geothermal reservoirs and confirming whether they can support commercial power generation. Some of the main activities in this stage include:

Seismic surveys: These surveys use vibration waves to create detailed maps of underground rock structures and identify potential geothermal reservoirs. The cost for a seismic survey can range from $500,000 to $4 million depending on the site location and survey scale (https://finmodelslab.com/blogs/startup-costs/geothermal-energy-exploration-startup-costs).

Test wells: Exploratory and temperature gradient wells are drilled to directly detect resources and measure underground temperatures. Each test well may cost $1-3 million to drill and complete (https://data.nrel.gov/submissions/8). Multiple wells are often needed to fully characterize a geothermal site.

Resource confirmation: After initial surveys and test wells, more extensive drilling and testing confirms the geothermal resource’s extent, temperatures, flow rates and other characteristics. This stage ensures adequate resources are available to support a power plant. Total exploration costs often range from $10-30 million before resource confirmation is achieved (https://science.howstuffworks.com/environmental/green-tech/energy-production/artificial-geothermal-energy4.htm).

Power Plant Construction

The cost of constructing a geothermal power plant can vary significantly depending on the plant’s size and components. According to the World Energy Council, installation costs rose from $2,620 per kilowatt (kW) in 2010 to $4,468 per kW in 2020 (Why Cost of Geothermal Power Plants Will Remain High).

For a typical 50 MW geothermal power plant, construction costs can range from $125 million to over $300 million. Larger plants above 100 MW may cost $500 million or more to construct. Major cost factors include site preparation, drilling wells, installing turbines and generators, building access roads, and acquiring permits.

Site preparation involves clearing the land and preparing foundations. This can cost several million dollars depending on the terrain. Drilling production and injection wells accounts for up to half of plant construction costs. A 50 MW plant may require 20-30 wells drilled thousands of feet underground at $2-6 million per well.

Permitting costs will also be substantial, potentially over $10 million, to comply with environmental regulations. Local, state, and federal permits take 1-3 years to acquire. Overall, constructing an efficient geothermal power plant is a complex, capital-intensive process.

Piping Costs

The piping network is one of the biggest costs associated with installing a geothermal system. The piping carries water or a water-antifreeze solution through the ground loop to transfer heat between the earth and the heat pump unit. The type of piping and amount needed depends on the loop design.

Common piping materials include polyethylene (PEX), polypropylene (PP), and high-density polyethylene (HDPE). HDPE pipe is generally the least expensive option at around $0.50-$2 per foot installed, with PEX and PP piping costing $1-$4 per foot. Piping costs are estimated at $2,500-$5,000 for a typical residential system, but can reach $10,000 or more for larger properties [1].

Installation costs account for most of the piping expense. The pipes need to be buried underground at depths of 4-6 feet to reach the stable temperatures. Trenching equipment, specialized fusion welding, and labor can add $10-$15 per foot in installation costs. Overall, piping installation runs $15-$30 per linear foot on average.

Maintenance

Once a geothermal power plant is constructed and operational, ongoing maintenance costs are relatively low compared to other types of power plants. According to the U.S. Energy Information Administration, operation and maintenance (O&M) costs for geothermal plants range from $0.01 to $0.03 per kWh generated [1]. This is significantly lower than natural gas plants, which have O&M costs of $0.03 to $0.04 per kWh, or coal plants, which range from $0.02 to $0.04 per kWh [2].

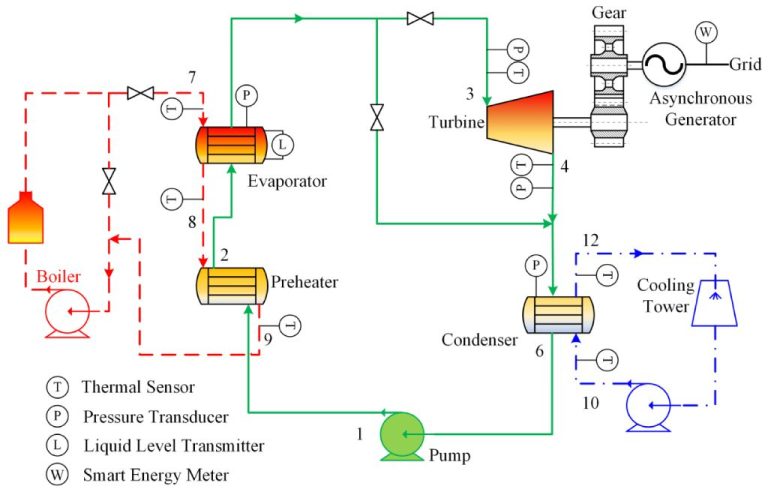

Routine maintenance activities at a geothermal plant include monitoring and maintaining the wells, pipelines, turbines, generators, and other infrastructure. Major overhauls of the turbine-generator may be needed every 5-10 years. Unplanned repairs or replacements of pumps, valves, and other components add to the ongoing costs. However, geothermal plants have proven to be extremely reliable, often achieving capacity factors over 90% with minimal unplanned outages [3].

Financing

The financing costs for a geothermal power plant are dependent on the interest rates and payback period. According to Geothermal power plants: financing and construction loans, interest rates for geothermal projects typically range from 6-8%. The payback period, which is the amount of time needed for the revenues to cover the total costs, is generally 15-25 years for geothermal power plants.

Higher interest rates and longer payback periods result in increased financing costs. Most geothermal projects utilize a combination of debt and equity financing. The debt portion often comes from commercial banks or public financing entities. Equity financing may come from utility companies, independent power producers, or investment funds. Securing favorable interest rates and financing terms is key to controlling the overall costs of a geothermal power plant project.

Tax Incentives

The federal government offers a tax credit to offset some of the costs of installing a geothermal heat pump system. According to the Energy Star website, the tax credit covers 26% of the costs for systems installed in 2022, dropping to 22% in 2023. The credit can be claimed on IRS Form 5695 for the tax year when the system was installed. There are eligibility requirements, such as the system must meet Energy Star efficiency criteria.

Many U.S. states also offer additional incentives for geothermal systems, including tax credits, grants, loans and rebates. For example, California offers a sales and use tax exemption on equipment for new geothermal heat pump installations according to the California Energy Commission. Illinois provides a tax credit equal to 20% of qualified expenditures up to $20,000 under its Geothermal Energy Incentive Act per Enertech. It’s recommended to check with your state energy office to find incentives available in your location.

Total Cost Ranges

The total cost of a geothermal power plant can vary significantly depending on the size of the plant, the drilling depth required, and the type of geothermal resource used. According to the US Department of Energy, the average installed cost for geothermal power plants in the US ranges from around $2,500 per kW for conventional hydrothermal resources to $4,000 per kW for enhanced geothermal systems (EGS) [1].

For a 50 MW geothermal power plant utilizing conventional hydrothermal resources, the total installed costs could range from $125 million to $150 million. For an EGS plant of the same size, total costs may be $200 million or higher. Larger plants over 100 MW may achieve some cost savings through economies of scale and could cost around $2,000-$3,000 per kW installed.

The total budget for a geothermal project must also account for resource exploration, well drilling, power plant construction, piping installation, and other related costs. Additional financing costs will also be incurred. While geothermal power requires high upfront capital costs, the ongoing operation and maintenance costs are relatively low once the plant is constructed.

Conclusions

Summary

Overall, the upfront cost of setting up a geothermal energy system can range from $3,000 per kW for smaller residential systems up to $6,000 per kW for larger commercial operations. The high initial investment is due to expenses like drilling, resource exploration, plant construction, and installation of underground piping. However, geothermal systems have relatively low maintenance costs and can last for decades. There are also tax credits available in the U.S. to help offset 30% of system costs.

Key Takeaways

The key takeaways on geothermal energy costs include:

- Drilling accounts for about 25-50% of total costs

- Larger systems benefit from economies of scale and have lower per kW costs

- Tax incentives in the U.S. can reduce net system costs by up to 30%

- Lifetime costs are very competitive with conventional energy when factoring in decades of free energy

Future Outlook

With increasing emphasis on renewable energy and climate change mitigation, geothermal is likely to play a bigger role in the global energy mix going forward. Costs are expected to decrease as drilling techniques improve and more economies of scale are achieved. This will make geothermal even more competitive as an alternative to fossil fuels.