How Much Does A Wind Generator Cost?

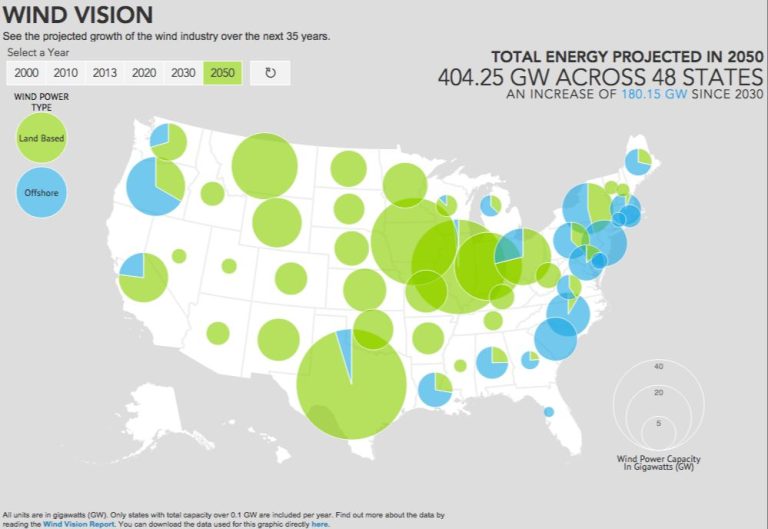

Wind power has emerged as one of the fastest growing sources of renewable energy worldwide. As concerns about climate change and energy security rise, many countries are investing heavily in wind power to reduce reliance on fossil fuels. Global wind power capacity reached 743 GW by the end of 2020, producing around 5% of the world’s total electricity demand.[1] In the United States alone, wind power capacity grew from 25 GW in 2008 to 122 GW in 2020.[2] With this rapid growth, there is increasing focus on the costs associated with wind power generation. This article provides an overview of the major cost components and factors that determine the total price tag of wind turbines and wind farms. We examine turbine costs, balance of system costs, operation and maintenance costs, capacity factors, and other variables that impact the levelized cost of wind energy. Understanding the costs of wind power will help policymakers, utilities, and consumers make informed decisions about investing in and expanding this important renewable energy source.

Types of Wind Turbines

There are two main types of wind turbines: horizontal-axis and vertical-axis turbines. Horizontal-axis turbines are most common today and have blades that rotate perpendicular to the wind. Vertical-axis turbines have blades that rotate parallel to the wind. Vertical-axis turbines can further be classified as Savonius or Darrieus designs. Savonius turbines have scoops to catch the wind while Darrieus turbines use airfoils that generate lift as they spin.

Wind turbines are also classified by size and power capacity. Small turbines can be just a few kilowatts while large utility-scale turbines can be multiple megawatts. The largest wind turbines today have capacities over 10 MW. Turbine sizes between 1.5 to 3 MW are most common for onshore wind farms.

Sources:

https://www.eia.gov/energyexplained/wind/types-of-wind-turbines.php

https://en.wikipedia.org/wiki/Wind_turbine

Major Components

The major components of a wind turbine include the nacelle, rotor blades, tower, and foundation. The nacelle sits atop the tower and contains the gearbox, generator, controller, and brake (1). The rotor blades are attached to the nacelle and rotate when wind strikes them. Modern wind turbine rotors consist of three blades made of fiberglass or carbon fiber. The tower supports the nacelle and rotor blades, typically standing over 260 feet tall. Towers are made from tubular steel, concrete, or steel lattice. The foundation provides stability, anchoring the turbine to the ground (2). Foundations vary by location but generally consist of concrete slabs or pilings extending 6 to 30 feet underground.

Size and Capacity

The size and power capacity of wind turbines can vary greatly depending on the model and manufacturer. Here are some typical size ranges:

Small turbines (residential use):

- Height: 30-100 feet

- Rotor diameter: 6-20 meters

- Power capacity: 1-100 kW

Medium turbines (small businesses, schools):

- Height: 100-400 feet

- Rotor diameter: 40-80 meters

- Power capacity: 250 kW – 2 MW

Large turbines (utility-scale):

- Height: 300-600 feet

- Rotor diameter: 100-140 meters

- Power capacity: 2-5 MW

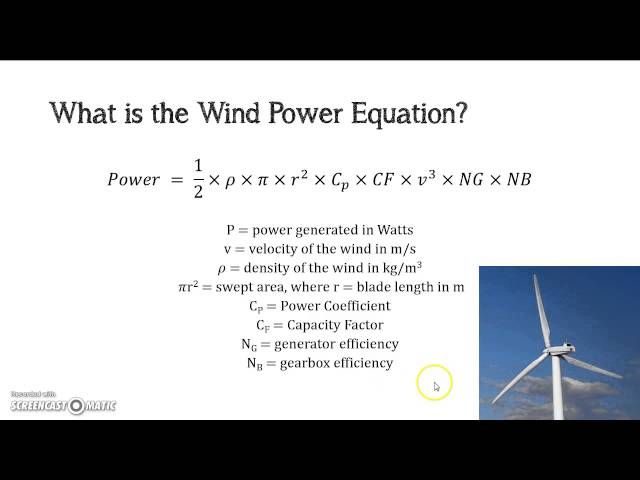

According to the U.S. Department of Energy, the average power capacity of newly installed wind turbines in the U.S. in 2022 was 3.2 MW, up from 2.3 MW in 2017 [1]. Factors affecting a turbine’s power output include wind speed, rotor diameter, and turbine height.

Manufacturing Costs

The manufacturing costs for a wind turbine can vary greatly depending on the size and components used. However, some typical costs include:

Material costs – These make up a significant portion of manufacturing expenses. Raw materials like steel, fiberglass, copper wiring, and electronics can range from 50-70% of total costs.1

Labor costs – Skilled technicians and engineers are required for the design, assembly, and testing of wind turbines. Labor accounts for about 20% of manufacturing costs on average.2

Transportation costs – Transporting the large components over land and sea can be expensive. Costs vary depending on distance, but transportation may be 5-15% of total manufacturing expenses.3

Economies of scale – Producing larger batches helps reduce average costs through bulk material purchases and streamlined processes. Manufacturing costs per MW capacity tend to drop as turbine size increases.1

Balance of System Costs

Balance of system (BOS) costs include all infrastructure and components required to support the wind turbines at a wind farm. These costs typically account for 20-30% of the total installed cost of a wind project. Some of the major balance of system cost components include:

- Site preparation – Clearing vegetation, grading, excavating, access roads, crane pads, turbine foundations, underground electrical collection systems.

- Electrical infrastructure – Substations, transformers, towers, poles, conductors, switchgear, monitoring and control systems.

- Roads – Onsite access roads and public road upgrades for construction and maintenance.

- Cabling – Collection system, transmission lines.

- Construction – Mobilization, staging, foundations, installation, demobilization.

According to NREL, balance of system costs for land-based wind power plants in 2019 ranged from $370-585/kW for plants between 10-150 MW. Larger projects can achieve some economies of scale. Costs are also influenced by terrain, labor rates, permitting requirements and other factors at each unique site.

Trends show balance of system costs declining only slightly in recent years as the industry matures. However, there are still opportunities to optimize turbine spacing, improve foundation designs, and streamline electrical infrastructures to further reduce balance of system costs in the future.

Installation Costs

The installation costs for a wind turbine can be significant. Some of the main costs include:

Crane rental – Most wind turbines are extremely large and heavy, requiring the use of cranes to lift and position them at the installation site. The crane rental costs can easily be tens of thousands of dollars per turbine.

Construction and civil works – The site must be graded and prepared with proper access roads and foundation pads for the turbines. This requires excavation, grading, foundation construction, and access road building which requires heavy construction equipment and labor.

Labor – A professional installation crew is needed to oversee the transportation, construction, and final assembly and erection of the wind turbine. This is highly skilled labor and can cost thousands per turbine.

Installation costs are generally higher for offshore wind turbines compared to onshore (Weatherguardwind.com). Offshore sites require specialized marine vessels, underwater cabling, and more complex foundations resulting in much higher costs in the range of 2-5x the installation price of onshore turbines.

Operation and Maintenance

Wind turbines require regular maintenance and repairs to keep them operating efficiently. Routine maintenance includes inspecting components and lubricating parts according to the manufacturer’s schedule, typically 1-2 times per year. This involves minor repairs and component replacements such as filters, brake pads, and bearings, which may cost $5,000-$10,000 annually (https://o-innovations.com/).

More significant unplanned repairs include gearbox refurbishment or replacement, generator rewinds, blade repairs, and electrical repairs. The frequency and costs of repairs increase as the turbine ages. One study found average unplanned maintenance costs to be $30-$50 per kW of capacity per year (https://www.jamesdysonaward.org/2018/project/o-wind-turbine).

Turbine owners commonly take out insurance policies to protect against costs from catastrophic failures or natural disasters. Rates vary around 1-2% of equipment cost annually. Overall, operations and maintenance costs tend to average $10-$15 per MWh generated over the turbine’s lifetime.

Total Lifetime Costs

The total lifetime cost of a wind turbine includes both upfront and long-term ongoing costs. The upfront costs include the turbine itself, foundation, electrical infrastructure, and installation. According to the National Renewable Energy Laboratory (NREL), the average upfront capital cost for a land-based wind turbine in 2020 was around $1,470 per kilowatt (kW) of capacity.[1]

However, wind turbines have a long lifespan, typically 20-25 years. So it’s important to also consider the ongoing operation and maintenance (O&M) costs over the turbine’s lifetime. NREL estimates average O&M costs to be around $51/kW per year. This covers regular maintenance, repairs, spare parts, insurance, and administration.[1]

To determine total lifetime costs, you must multiply the upfront capital cost per kW by the turbine’s capacity in kW. Then add the yearly O&M cost per kW multiplied by the number of years of operation. Financing costs can also be a significant expense, as projects typically require debt financing.

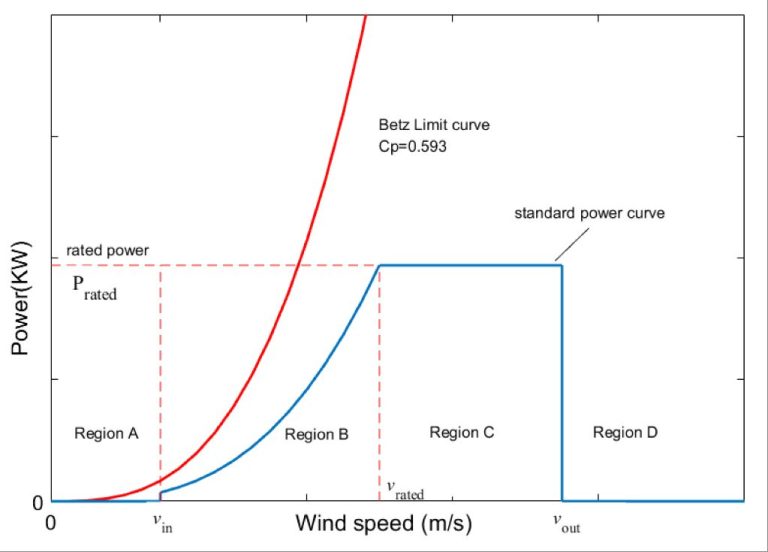

The capacity factor, which measures the turbine’s actual productivity vs theoretical maximum, is also crucial. Onshore wind turbines in the U.S. have an average capacity factor around 35-45%. More productive turbines will generate more total power over their lifetime, lowering the levelized cost per kWh.

Given all these factors, NREL estimates the levelized lifetime cost of land-based wind energy to be $37-44 per MWh. So a typical 2-3 MW turbine would cost $2-4 million upfront, plus financing, maintenance, and other expenses over its 20-25 year lifespan.[2]

Overall, wind power remains very cost-competitive with other electricity sources. And continued technology improvements are further reducing upfront and operating costs over time.

[1] https://www.nrel.gov/docs/fy21osti/77234.pdf

[2] https://www.nrel.gov/docs/fy21osti/77234.pdf

Latest Cost Trends

The cost of wind energy has been steadily declining over the past decade. According to the 2022 Land-Based Wind Market Report from the U.S. Department of Energy, the average installed cost of wind projects in 2021 was $1,500/kW, down 10% from the 2020 average cost of $1,675/kW (DOE 2022). Wind turbine prices specifically averaged $800–$950 per kW in 2021, compared to over $1,800 per kW in 2008 (Canary Media 2022).

Experts project that wind energy costs will continue to decrease in the future as technology improves. Larger, more efficient turbines and optimized wind farm designs are expected to drive cost reductions. Continued growth in wind energy demand and manufacturing scale will also put downward pressure on prices. The DOE has set a goal to cut the cost of land-based wind energy by 50% by 2030 from a 2020 baseline (DOE Strategic Plan). Therefore, the long-term outlook for wind power is very positive as it becomes increasingly cost competitive with conventional energy sources.