How Many Pv Cells In A Solar Panel?

Photovoltaic (PV) cells are semiconductor devices that convert sunlight directly into electricity. Multiple PV cells are connected together in an assembly and encapsulated in a protective frame to create a solar panel, also known as a solar module. The number of PV cells in a solar panel can vary depending on several factors.

This article explores how many PV cells are typically contained within a standard solar panel and what determines the cell count.

The main question we aim to answer is: How many PV cells are included in a common residential or commercial solar panel?

Typical Number of Cells

Solar panels are composed of many individual solar cells wired together. The typical number of solar cells in a standard residential or commercial solar panel ranges from 60 to 72 cells. However, this can vary depending on the size and power output of the panel. Most commonly you’ll find solar panels with either 60 or 72 monocrystalline or polycrystalline silicon cells.

For a standard 250-300 watt solar panel that is around 5 feet by 3 feet in size, 60 cells is standard. For larger panels that produce more wattage, such as a 400 watt panel, they may contain 72 cells. So in general, more cells allows the panel to produce more electricity.

Factors That Determine Cell Number

The number of PV cells in a solar panel depends on several key factors:

- Panel size – Larger panels require more cells to cover the entire surface area. Standard residential panels are around 65 inches by 39 inches. Smaller panels for RV’s or boats may only contain a few dozen cells.

- Power output – More solar cells allows the panel to produce more wattage. Panels typically range from 250W to 400W for home use. More cells increases power production.

- Cell efficiency – If the PV cells have a higher efficiency rating, fewer are needed to get the same wattage. Typical monocrystalline cells are 20-24% efficient. More advanced cells can reach over 26% efficiency.

Optimizing these variables allows manufacturers to determine the number of solar cells needed per panel. Higher efficiency cells require less physical space to generate the same output. Panel size and power needs dictate the total number of cells.

Standard Panel Sizes

Most residential solar panels come in standard sizes and cell counts. Standard solar panels for homes are generally sized between 250-400 watts. Commercial systems tend to use larger panels, typically 300+ watts. Here are some common solar panel sizes and their approximate number of PV cells:

- 250-280 watt panels – Typically 60 cells

- 300+ watt panels – Typically 72 cells

- 320-340 watt panels – Frequently 96 cells

- 360-400+ watt panels – Often 120 cells

So in general, a typical 250-400 watt residential solar panel will contain 60-120 PV cells. Higher wattage commercial panels may have up to 156 cells. The number of cells corresponds to the physical size of the panel. Higher wattage panels need more cells to generate more power.

Cell Efficiency

The efficiency of a solar cell determines how much electricity it can generate from a given amount of sunlight. More efficient cells are able to convert a greater percentage of the solar energy that hits them into usable electricity. This means that panels with higher efficiency cells require fewer cells to produce the same amount of power as a panel with less efficient cells.

Most residential and commercial solar panels on the market today have average cell efficiencies between 15-22%. High-end premium panels may reach up to 25% efficiency. On the low end, some cheaper panels may have efficiencies around 12-14%. Comparing a premium 25% efficient panel to a budget 14% efficient panel, the premium panel would require about 43% fewer cells to achieve the same power output. This allows manufacturers to make smaller and less expensive panels by using higher efficiency cells.

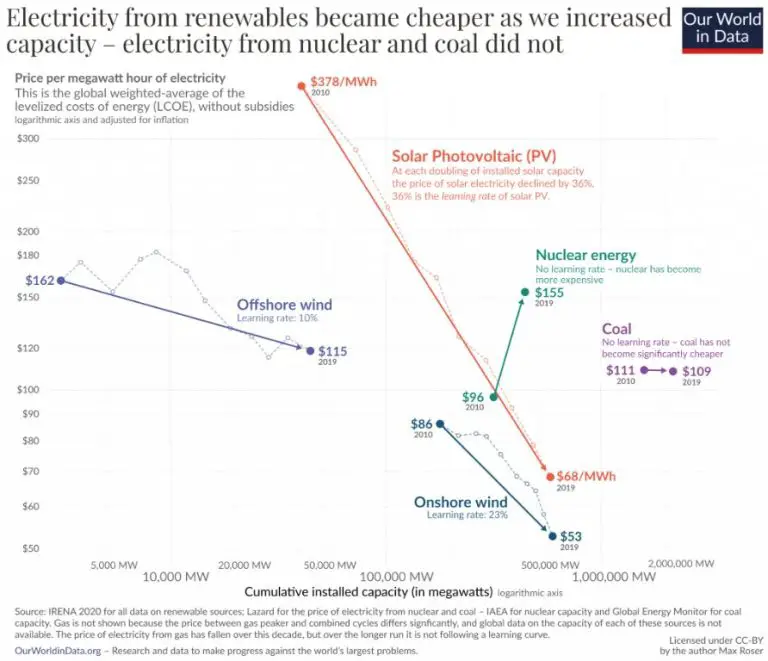

Improving solar cell efficiency is an area of continued research and development in the solar industry. With further innovations in solar cell technology, manufacturers can keep reducing the number of cells needed to generate a given amount of electricity. This in turn brings down costs and makes solar power increasingly affordable and accessible.

Power Output

The number of PV cells in a solar panel directly impacts its power output. More cells allow a panel to produce more electricity. Power output ratings are measured in watts – standard panels range from around 250W to 400W for residential systems. Higher power panels generally have a larger number of cells compared to lower power models.

For example, a 300W panel would typically contain around 60 cells, while a 400W panel might have 72 cells. By adding more cells, manufacturers can increase the current and voltage produced by the panel, resulting in higher overall wattage. The cell efficiency also plays a role, but in general, more cells equals more power capacity.

So when designing a solar array, installers will select appropriately-sized panels based on the power needs of the system. Larger homes and commercial systems require panels with higher wattage to meet their energy demand. The number of panels depends on the space available, but the power per panel should be optimized for the intended application.

Monocrystalline vs. Polycrystalline

Monocrystalline and polycrystalline solar panels differ in the number of photovoltaic cells they contain. Monocrystalline panels are made from a single cylindrical silicon crystal, whereas polycrystalline panels contain many smaller silicon crystals or grains.

Due to their higher purity and efficiency, monocrystalline panels require fewer cells to produce the same wattage as polycrystalline panels. A typical 300W monocrystalline panel may contain 72 cells, while a polycrystalline panel of the same wattage would have 84-96 cells.

The cells in monocrystalline panels are all perfectly aligned and cut from a single cylindrical silicon ingot. This organized structure allows each cell to absorb light more effectively. Poly panels have a more randomized cell pattern with gaps and imperfections.

Overall, monocrystalline panels maximize power output with fewer PV cells. However, polycrystalline panels can be slightly cheaper to manufacture due to lower silicon purity requirements.

Thin-Film PV

Thin-film PVs use fewer cells compared to traditional crystalline silicon solar panels. Rather than using rigid silicon cells, thin-film PVs apply a thin layer of photovoltaic material onto a flexible substrate. This allows thin-film panels to cover a larger surface area with less photovoltaic material. While a standard crystalline silicon solar panel may contain 60-72 individual cells, a comparably sized thin-film module may contain only 6-12 large thin-film cells. The thin-film cells are electrically connected in series to produce the desired output voltage. Some of the common thin-film materials used in PVs include cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and amorphous silicon (a-Si). The flexible and lightweight nature of thin-film modules enables innovative applications like building-integrated photovoltaics. However, thin-film PVs tend to have lower efficiency ratings than crystalline silicon panels.

Wiring and Configuration

Solar panels contain photovoltaic (PV) cells that convert sunlight into electricity. These cells are wired together in specific configurations to optimize the panel’s voltage and current output.

The most common configuration is series wiring. PV cells generate a small voltage, typically around 0.5V each under load. By wiring cells in series, the voltages add up to achieve a higher overall voltage. For example, wiring 36 cells in series to produce 18V. This allows the solar panel to charge a 12V or 24V battery bank.

Solar panels can also contain parallel cell wiring to increase current. Parallel wiring combines the current of each cell while maintaining the same voltage. For home systems, solar panels typically contain series cell strings that are then combined in parallel to deliver higher current.

By adjusting the series and parallel wiring ratios, manufacturers can optimize a solar panel’s output characteristics for different applications. The number of cells and wiring layout will depend on the target power output and voltage requirements.

Conclusion

The number of PV cells in a solar panel can vary substantially based on the size, type, and output of the panel. Standard residential solar panels often contain 60, 72, or 96 monocrystalline silicon cells. The number of cells is a key factor determining the panel’s voltage and wattage. More cells allow the panel to produce more electricity, but also increase manufacturing costs. While panels with 60 cells are common for home installations, larger utility-scale arrays may utilize panels with over 100 cells to maximize power production. Panel and cell efficiency also play important roles – more efficient cells require fewer to produce the same output. Regardless of the exact number, PV cells collectively produce direct current

electricity when exposed to sunlight, which is then converted to alternating current for household use. The cell count directly informs the panel’s production capacity and electricity generation potential.