How Is Biomass Waste Produced Into Biofuel?

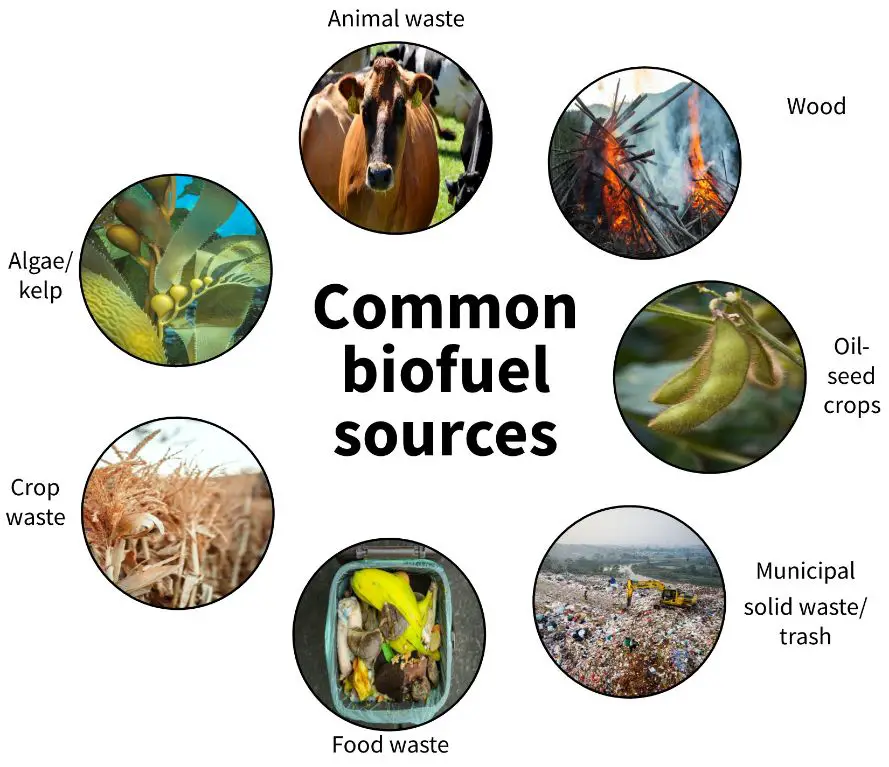

Biomass waste refers to organic materials that are byproducts or residuals from various industrial, agricultural and municipal activities. This includes materials like crop residues, wood waste, food processing waste, animal manure, and municipal solid waste. Biofuels are fuels derived from biomass that can be used to generate energy. The most common biofuels are ethanol and biodiesel.

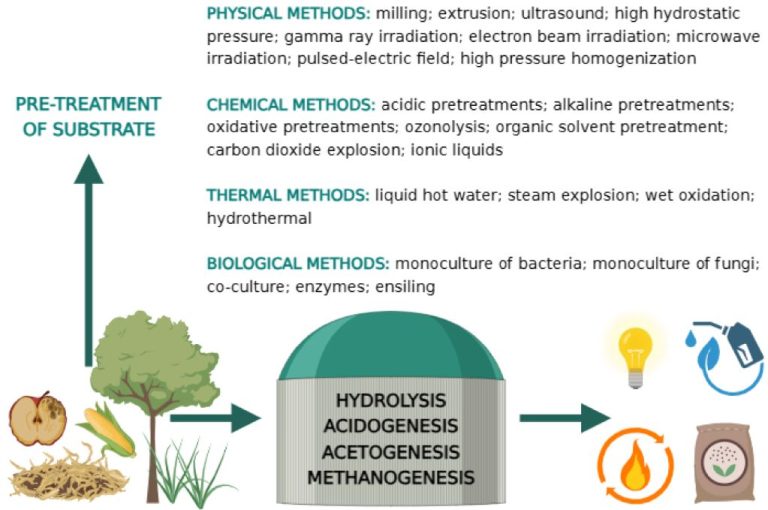

Biofuel production involves converting biomass waste into usable fuel through various processes like fermentation, gasification, pyrolysis and anaerobic digestion. The goal is to take organic waste materials and convert the organic carbon and energy stored in them into a fuel that can be used for transportation, heating, electricity generation and more. The production process generally involves pre-treating the biomass, breaking down the organic molecules through a conversion process, and then separating and purifying the fuel.

Sources of Biomass Waste

Biomass waste that can be converted into biofuel comes from several sources:

Agricultural residues: Leftover materials from agriculture like corn stover (stalks, leaves, husks), wheat straw, rice straw, sugar cane bagasse, nut shells, and fruit pits provide a large source of biomass waste.

Food waste: Uneaten food scraps and spoiled food from homes, restaurants, grocers, and institutional sources is another significant contributor.

Municipal solid waste: Biodegradable waste like paper, cardboard, yard trimmings, wood, and food scraps from municipal garbage collection contains convertible biomass.

Forestry waste: Logging residues like sawdust and cut branches/tree tops as well as waste wood from mills and construction provide biomass from forestry sources.

Animal manure: Fecal waste from livestock and poultry farms serves as an abundant source of biomass for conversion.

Pre-Treatment

Converting biomass waste into biofuel requires several pre-treatment steps to prepare the raw material. The main pre-treatment processes are drying, size reduction, and separation.

Drying reduces the moisture content of wet biomass feedstocks. Methods like sun drying, oven drying, or applying heat allow water to evaporate. Removing moisture is crucial, as high water content can inhibit conversion processes.

Size reduction breaks down biomass into smaller, uniform pieces through milling, chipping, or grinding. Smaller particle sizes increase surface area and allow better access for solvents during conversion. Hammer mills, shredders, and chippers are commonly used.

Separation splits biomass into its main components. Techniques like screening, crushing, leaching, and flotation remove non-cellulosic compounds like resins, proteins, and inorganic salts. This purification and fractionation streamline conversion by extracting only materials useful for biofuel production.

Conversion Processes

There are two main types of conversion processes used to produce biofuels from biomass waste: biochemical conversion and thermochemical conversion.

Biochemical conversion involves using bacteria, microorganisms, or enzymes to break down biomass into sugars or oils that can then be converted into biofuels. The two main biochemical conversion processes are anaerobic digestion and fermentation.

Anaerobic digestion uses anaerobic bacteria to break down biodegradable material in an oxygen-free environment. This produces biogas which is mostly methane and carbon dioxide. The biogas can be used directly as fuel or further processed into transportation fuels like renewable natural gas.

Fermentation uses yeast or bacteria to convert sugars from biomass into ethanol that can be used as a transportation biofuel. The biomass is first pre-treated to release sugars which are then fermented using microorganisms. For example, corn starch can be broken down into glucose sugars and then fermented to produce ethanol.

Thermochemical conversion uses heat, pressure, and catalysts to convert biomass into bio-oil, syngas, or charcoal. The three main thermochemical processes are gasification, pyrolysis, and liquefaction.

Gasification converts biomass into syngas at high temperatures with some oxygen. Syngas is primarily hydrogen, carbon monoxide and carbon dioxide. The syngas can be further processed into liquid biofuels.

Pyrolysis rapidly heats biomass in the absence of oxygen to produce bio-oil which can be refined into transportation fuels. Different pyrolysis temperatures favor the production of either bio-oil or syngas.

Liquefaction uses a catalyst and solvent to convert wet biomass into liquid bio-crude at high pressure and temperature. The bio-crude can then be refined into final biofuels.

Anaerobic Digestion

Anaerobic digestion is a process that uses bacteria to break down biomass waste in the absence of oxygen, resulting in the production of biogas. This process occurs inside a sealed oxygen-free container called an anaerobic digester. Inside the digester, anaerobic bacteria consume organic material and produce a mixture of gases, primarily methane and carbon dioxide.

The anaerobic digestion process involves three steps:

- Hydrolysis – Complex organic polymers like carbohydrates are broken down into simple sugars, amino acids, and fatty acids.

- Acidogenesis – The products of hydrolysis are further digested by acidogenic bacteria into simple organic acids, carbon dioxide, hydrogen gas, and alcohol.

- Methanogenesis – Methane producing archaea convert the organic acids and alcohols into methane gas and carbon dioxide.

The biogas produced is rich in methane and can be used to generate electricity, heat, or fuel. Anaerobic digestion is advantageous because it reduces waste volumes going to landfills, decreases greenhouse gas emissions from waste, and generates renewable energy. It’s a sustainable way to divert organic waste from landfills and produce biofuel.

Fermentation

Fermentation is a process in which yeast and bacteria converts sugars into ethanol and other byproducts. The biomass waste material, such as agricultural residues, wood wastes, municipal solid wastes and crop residues, contain cellulose and lignin which needs to be broken down into sugars before fermentation.

Pre-treatment processes like acid or enzymatic hydrolysis are used to break down the cellulose and hemicellulose components into simple sugars like glucose. The liberated sugars are then fermented using yeast or bacteria which metabolizes the sugars into ethanol. The most commonly used organism is Saccharomyces cerevisiae yeast which can produce ethanol concentrations of up to 15%.

Optimizing parameters like pH, temperature and nutrient levels can improve ethanol yield through fermentation. The resulting product is a liquid fuel called bioethanol which can directly replace gasoline. With further processing, bioethanol can also be blended with traditional fuels or converted into other products like bio-based jet fuel. The leftover organic matter from fermentation can be used as livestock feed.

Gasification

Gasification is a thermal conversion process that converts biomass into a combustible gas mixture known as syngas. It involves heating the biomass at high temperatures ranging from 700°C to 1000°C in the presence of a controlled amount of oxygen. The process breaks down the biomass into its basic chemical constituents and generates syngas composed primarily of hydrogen, carbon monoxide, carbon dioxide and methane.

During gasification, the biomass undergoes different processes:

- Drying – Moisture in the biomass is evaporated

- Pyrolysis – The biomass decomposes to produce char, tar and gaseous products when heated in the absence of oxygen

- Oxidation – The pyrolysis products react with oxygen producing carbon dioxide, carbon monoxide and heat

- Reduction – The pyrolysis products react with carbon dioxide and steam to produce carbon monoxide, hydrogen and methane

The produced syngas can be used to generate electricity, produce transportation fuels or manufacture chemicals and fertilizers. Gasification offers high efficiency and flexible applications for biomass conversion.

Pyrolysis

Pyrolysis converts biomass into liquid bio-oil, syngas, and biochar by heating the biomass in the absence of oxygen. In this process, the biomass is heated to temperatures typically between 300-600°C, causing it to thermally decompose into vapors and char. The process happens quickly, with vapors and char being immediately removed from the reactor once formed.

The vapors produced during pyrolysis consist of organic compounds like acids, alcohols, ketones, sugars, and phenolics. These hot vapors are quickly cooled and condensed into a dark brown liquid bio-oil. The non-condensable gases produced form the syngas, which contains carbon monoxide, carbon dioxide, methane, hydrogen, and other light hydrocarbons. The solid char left behind has a high carbon content and is called biochar.

Pyrolysis offers some key advantages in converting biomass to biofuels. The liquid bio-oil is energy dense and can be refined into transportation fuels. The syngas can provide the power needed for the pyrolysis process. And the biochar can improve soil quality when applied as a soil amendment. Overall, pyrolysis provides a flexible platform for generating multiple useful biofuels from biomass waste.

Liquefaction

Liquefaction is a thermal process that converts biomass into liquid bio-oil called biocrude using high heat and pressure. The biomass is reacted in water at temperatures ranging from 300-350°C and pressures between 5-20 MPa with the addition of catalysts like sodium carbonate.

The high temperature and pressure break down the biomass polymers into smaller molecules. The water acts as a solvent and the catalysts help optimize decomposition. This process produces a liquid bio-oil along with some gaseous byproducts.

The bio-oil can be refined further to produce high quality hydrocarbon fuels. Liquefaction has the advantage of converting wet biomass directly without needing drying. It produces a higher energy density fuel compared to pyrolysis oils. However, the high temperature and pressure requirements add to the capital costs. Research is ongoing to improve the quality and economic viability of biocrude production from biomass liquefaction.

Conclusion

There are several key processes for converting biomass waste into biofuels. Anaerobic digestion uses microorganisms to break down organic matter in the absence of oxygen, producing biogas. Fermentation utilizes yeasts or bacteria to convert sugars into ethanol. Gasification uses high heat, pressure, and partial oxidation to produce syngas. Pyrolysis rapidly heats biomass in the absence of oxygen to generate bio-oil, syngas, and biochar. Liquefaction uses moderate heat and pressure to convert wet biomass into biocrude.

Converting biomass waste into biofuel is an important way to create renewable energy while also reducing pollution and greenhouse gas emissions from organic waste materials. The variety of technologies available allows the utilization of many different feedstock sources and the production of multiple fuel types to meet energy needs. Further research and development can enhance the efficiency and commercial viability of these biofuel production processes.