How Is Biomass And Energy Produced From Waste?

Biomass energy refers to energy generated from organic waste material. Biomass energy production from waste involves converting waste materials into useful energy through a variety of processes.

The main process involves collecting organic waste such as crop residues, wood waste, food waste, manure, and sewage sludge. The waste then goes through pre-processing steps to prepare it for energy conversion. Common conversion technologies include direct combustion, thermal conversion (gasification and pyrolysis), and biochemical conversion (anaerobic digestion and fermentation). The conversion process produces biogas, biofuel, or heat that can be harnessed to generate renewable electricity and transportation fuels.

The key benefits of generating energy from waste sources include:

- Diverts waste from landfills

- Reduces greenhouse gas emissions from waste decay

- Generates useful energy products

- Creates additional revenue streams

- Reduces reliance on fossil fuels

Types of Waste Sources

There are several major categories of waste that can be used for biomass and energy production:

Municipal Solid Waste (MSW)

MSW refers to waste collected by municipalities from households and businesses. It includes food waste, paper, plastics, textiles, glass, metals, and other materials. MSW is the largest source of waste biomass in most regions.

Agricultural Waste

Agricultural operations produce large volumes of biomass residuals including manure, crop residues, spoiled produce, and more. These materials can be converted into useful energy through anaerobic digestion, direct combustion, pyrolysis, and other methods.

Forestry Waste

Forestry waste consists of residual biomass like tree tops, branches, bark, and sawdust leftover from logging and milling operations. These materials can provide a renewable fuel source when processed into woodchips, pellets, or biogas.

Industrial Waste

Many industries produce organic waste streams that can be used for energy. Examples include whey from dairy processing, residuals from food and beverage production, wastewater sludge, and waste oils and solvents.

Sewage Sludge

Sewage sludge is the residual slurry produced during municipal wastewater treatment. It contains significant organic matter than can be anaerobically digested to produce biogas for electricity or heating.

Waste Collection

There are several methods used to collect waste and recyclable materials:

Curbside collection – This involves collecting waste and recyclables directly from households. Trucks visit homes on a weekly or biweekly schedule and collect bins left at the curb by residents.

Drop-off centers – Centralized locations where residents can bring their waste and recycling. This allows for a wider range of materials to be collected compared to curbside pickup.

Waste segregation – Separating waste into different categories makes it easier to recycle and process. Many areas require residents to sort their waste into bins for landfill trash, paper, metals, plastics, glass, yard waste, etc.

Recycling – Diverting waste materials like paper, glass, metals, and plastics so they can be turned into new products. This reduces waste volume and the need for new raw materials.

Pre-Processing

Before waste can be converted into biomass and energy, it often requires pre-processing to prepare the waste for conversion. This includes techniques like sorting, shredding, drying, compacting, and screening:

Sorting – Waste is sorted to separate out recyclable materials, remove contaminants, and categorize waste by type. This helps improve the efficiency of downstream processes.

Shredding – Size reduction through shredding makes the waste more uniform and easier to handle. It increases surface area for drying and conversion processes.

Drying – Removing moisture content makes waste materials easier to process. Thermal drying or mechanical dewatering can be used.

Compacting – Compaction reduces the volume of waste, making it cheaper to store and transport.

Screening – Screening separates waste into different size fractions. Oversized and undersized materials can be processed separately.

Conversion Technologies

There are several primary technologies used to convert waste into useful energy:

Incineration

Incineration involves the combustion of waste material at high temperatures. Incineration plants burn waste in a controlled environment to produce heat, which then generates electricity via steam turbines. Modern incineration plants include emissions control systems to limit air pollution.

Gasification

Gasification converts carbon-based waste into syngas through partial oxidation at high temperatures. The resulting gas mixture is then cleaned and can be used to generate electricity. Gasification enables more complete conversion and flexibility compared to incineration.

Pyrolysis

Pyrolysis heats waste in the absence of oxygen to produce char, oil, and syngas. The relative amounts can be controlled by varying temperature and heating rate. The char can be used as fuel, while the oils and gas can generate energy.

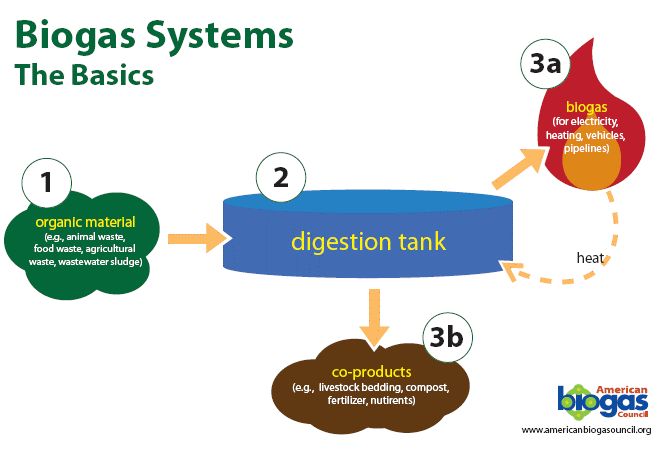

Anaerobic Digestion

Anaerobic digestion uses microorganisms to break down biodegradable waste in the absence of oxygen. This produces biogas containing methane that can be used to generate electricity. Anaerobic digestion is well-suited for wet organic waste streams.

Direct Combustion

Direct combustion is one of the most common and straightforward ways to convert waste into energy. It involves burning waste at high temperatures, typically around 850-980°C, to produce heat that can then generate electricity via steam turbines. There are two main types of direct combustion systems used for waste-to-energy conversion:

Mass burn incineration: Unprocessed waste is fed into a large combustion chamber where it is burned. The heat from combustion boils water to produce steam that spins a turbine connected to a generator to produce electricity. Mass burn systems can process large volumes of mixed waste efficiently.

Modular systems: Waste is pre-processed to remove non-combustibles then fed into smaller modular combustion chambers. Modular systems allow more control over air flow and combustion conditions for more efficient waste-to-energy conversion. The modular design also allows capacity to be expanded.

Direct combustion converts up to 90% of the organic material in waste into usable energy. However, it produces air emissions that must be tightly controlled. Advanced air pollution control systems are installed to clean flue gases before release. Overall, direct combustion provides a simple and effective waste disposal method that also generates renewable energy.

Thermal Conversion

Thermal conversion technologies break down organic materials using heat. The most common thermal conversion methods for waste biomass are gasification, pyrolysis, and plasma arc gasification.

Gasification involves heating waste biomass to high temperatures with some oxygen present. This converts the waste into syngas, which is primarily carbon monoxide, hydrogen, and carbon dioxide. The syngas can be burned directly for energy or further processed into fuels and chemicals. Gasification is useful for mixed heterogeneous waste streams.

Pyrolysis heats waste biomass without oxygen, which decomposes the material into solid char, liquid bio-oil, and gaseous compounds. Controlling the temperature allows optimization of the relative amounts of char, liquids, and gases produced. Pyrolysis produces high energy-density liquid bio-oils from waste biomass.

Plasma arc gasification uses extremely high temperatures from an electrical arc to break down waste into syngas. It can process diverse waste streams and is more tolerant of heterogeneous or contaminated feedstocks compared to other thermal conversion methods. However, it requires significant energy input to generate the plasma.

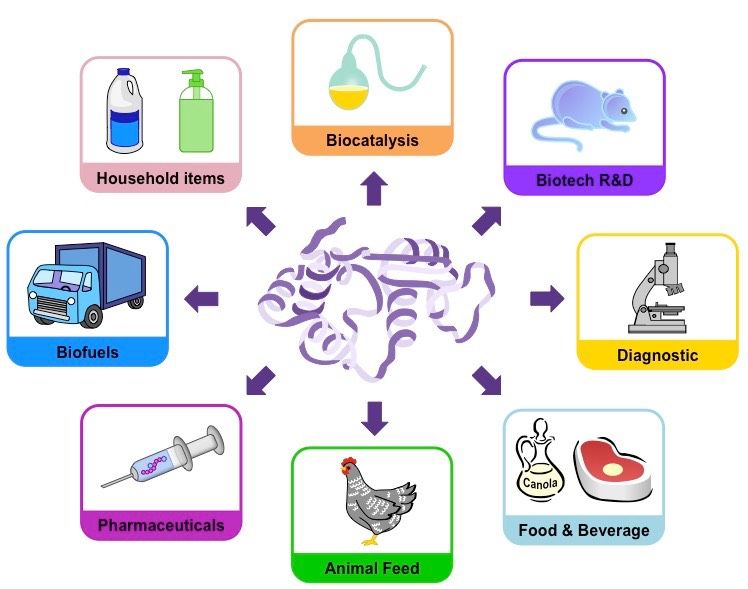

Biochemical Conversion

Biochemical conversion utilizes biological processes to convert organic waste materials into energy sources like biogas and biofuels. There are three main technologies:

Anaerobic Digestion

Anaerobic digestion uses microorganisms to break down biodegradable material in the absence of oxygen. This produces biogas, which is primarily composed of methane and carbon dioxide. The biogas can then be used to generate electricity and heat. Anaerobic digestion is commonly used for wet waste streams like food waste, agricultural residues, and sewage sludge.

Fermentation

Fermentation converts sugars and carbohydrates into alcohols, acids, gases, and other compounds using microorganisms like yeast and bacteria. The process happens in an oxygen-limited environment. Bioethanol is one common product, created by fermenting sugars from crops like corn and sugarcane. The resulting alcohol can be used as a transportation biofuel.

Composting

Composting allows aerobic microbes to break down organic matter into nutrient-rich humus. The final compost product can be used as a soil amendment or organic fertilizer. Composting is used for yard waste, food scraps, and other agricultural residues. It is less effective at generating usable energy than anaerobic digestion or fermentation.

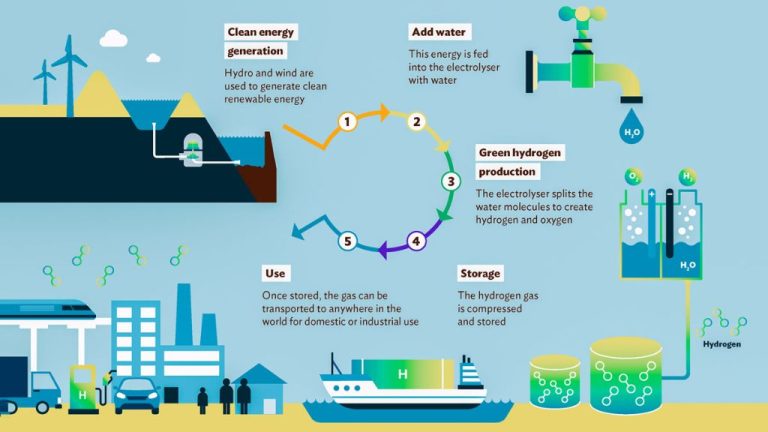

Energy Generation

There are several ways to generate energy from biomass and waste sources:

Steam turbines – A common way to generate electricity from biomass is by burning it to heat water, produce steam, and run the steam through a turbine. The steam spins the turbine blades which spin a generator to produce electricity. Steam turbines are a mature, reliable technology used with coal plants as well.

Gas engines – Biomass gasification produces a synthetic gas (syngas) that can be burned in a gas engine connected to a generator to produce electricity. Gas engines are internal combustion engines modified to run on syngas instead of gasoline or natural gas.

Fuel cells – Fuel cells are electrochemical devices that produce electricity by combining hydrogen and oxygen. The hydrogen can be produced from biomass through gasification and fed into a fuel cell. Fuel cells are clean and efficient but currently expensive compared to other technologies.

Combined heat and power (CHP) – Also called cogeneration, CHP systems generate both heat and electricity from biomass in one integrated system. The heat is used on-site which improves the overall efficiency. CHP systems are common with biomass plants, district heating, and industrial facilities.

Environmental Impact

The environmental impact of generating energy from waste depends on the types of waste used, the conversion technology, emissions controls, and waste disposal methods. However, in general converting waste to energy has lower environmental impacts compared to landfilling waste or using fossil fuels.

Emissions Control: Facilities generating energy from waste are required to follow strict emissions regulations that limit pollutants released. Methods like gas scrubbing, filters, and converter optimization reduce emissions of particulates, metals, acids, organics, and ozone-depleting compounds. Modern plants can match or even improve on the emissions from fossil fuel power plants.

Ash Disposal: After combustion, around 10% of waste volume remains as ash that requires disposal. While ash can contain heavy metals and other pollutants, modern plants solidify it into chemically stable blocks. Ash is then sent to monofills or recycled into construction materials. This is a significant improvement over directly landfilling unprocessed waste.

Comparisons to Landfills and Fossil Fuels: Energy from waste facilities produce less methane compared to landfills by destroying organic material rather than allowing anaerobic decomposition. They also offset fossil fuel power plants, reducing carbon dioxide emissions from coal and natural gas. Waste-to-energy is considered a form of renewable energy in many countries and can assist in meeting renewable energy targets.