How Effective Are Water Wheels?

A water wheel is a mechanical device that harnesses the power of flowing or falling water to turn a large wooden or metal wheel. The rotational motion and torque generated by the water wheel has been used for centuries for a variety of industrial applications.

Water wheels have a long history, with the earliest written reference dating back to around 400 BCE in Greece. They were widely used throughout the Middle Ages all across Europe for grinding grain, powering sawmills and hammermills, pumping water, and powering textile mills. Their use expanded greatly during the Industrial Revolution. [1]

The two main types of water wheels are vertical water wheels that are turned by water from above via gravity, and horizontal water wheels that are turned by the flow or impulse force of water from the side. The specific designs and applications of water wheels evolved greatly over time. [2]

Types of Water Wheels

There are three main types of water wheels: undershot wheels, overshot wheels, and breastshot wheels. https://www.engr.psu.edu/mtah/essays/threetypes_waterwheels.htm

Undershot wheels are positioned lower, with the bottom of the wheel immersed in the water. The moving water simply turns the wheel. They have lower efficiency but can work with low heads of water.

Overshot wheels are positioned higher, with the water flowing over the top of the wheel. The weight of the water falling turns the wheel. They have higher efficiency but require higher heads of water.

Breastshot wheels are intermediate between undershot and overshot. The water enters about halfway up the wheel. They are mid-range in terms of efficiency.

Mechanical Advantages

Water wheels are able to generate significant mechanical power from the kinetic energy of flowing or falling water. This is achieved through mechanical advantages that transform the kinetic energy into useful rotational power.

One key factor is gearing. Water wheels utilize gearing ratios to increase the rotational speed and torque generated. Large water wheels, such as undershot wheels, operate at low speeds. Through gearing, the low speed rotation can be converted into much higher speeds, while also increasing torque. This allows the water wheel to perform useful mechanical work like milling grains or pumping water (Energy Education).

Water wheels are also able to generate high levels of torque thanks to their large diameter designs. The paddles or buckets striking the water create a lever arm that generates torque. This torque can be further amplified through gearing (TeachEngineering).

The mechanical power generated by a water wheel depends on the volume and head of water. More volume and higher heads result in greater kinetic energy to be extracted by the wheel. Efficiencies of undershot wheels can reach 35-70%, while overshot wheels can reach 80% efficiency under optimal conditions (Energy Education).

Efficiency

The efficiency of a water wheel depends on several factors including the wheel design, construction, head of water, and flow rate. The most efficient water wheel designs are overshot and backshot wheels, which use the weight of falling water to drive the wheel. These designs can achieve up to 90% efficiency according to Wikipedia.

Research by Štigler measured the efficiency of overshot wheels under low heads of water and flow rates. The maximum efficiency achieved was 65%, lower than the typical 85% noted in literature. Efficiency was found to increase proportionally with head height. At heads of 0.5 m, efficiency ranged from 30-50%. At increased heads of 1.5 m, efficiency improved to 60-65%. This demonstrates the importance of gravitational potential energy for overshot wheel efficiency.

The flow rate of water must also be optimal. Too little flow will not sufficiently turn the wheel. But flow that is too fast will spill over rather than properly entering the buckets to utilize the weight and kinetic energy of the water. So both the head height and flow rate must be balanced to maximize efficiency.

Applications

Water wheels have been used for powering various industrial applications throughout history, with some of the main uses being in milling and pumping. They were an important source of power during the early Industrial Revolution before steam power became dominant.

One of the most common uses of water wheels was in grain mills for grinding wheat, corn, rye and other grains into flour. The rotary motion of the wheel was connected to a millstone that would grind the grain. Water wheels enabled the automation of flour production, replacing hand mills powered by human or animal strength.

Water wheels were also used for powering sawmills, fulling mills for thickening woolen cloth, crushing mineral ore, papermaking, forging iron, powering textile machinery and many other industrial processes. The power provided by water wheels was an essential factor in the growth of early mechanized industry.

Another widespread application was using water wheels for pumping water. Scoop wheels would bring water up from rivers or wells for irrigation and drainage. Some of the earliest examples of water pumps driven by water wheels date back to the Roman era.

By the 19th century, water wheels powered factories and mills throughout Europe and North America. They helped drive the Industrial Revolution by mechanizing former hand methods of production.

Decline

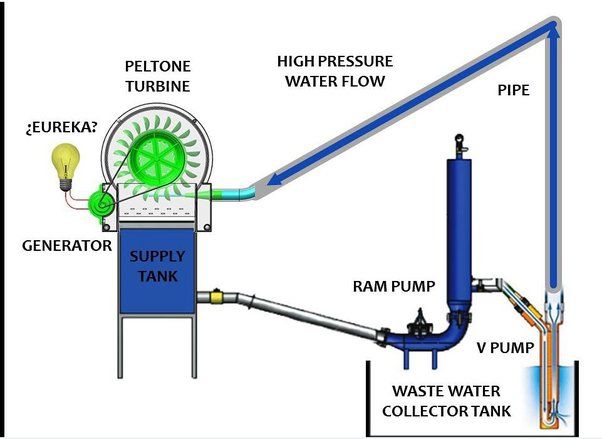

The decline of water wheels began in the 19th century with the development of steam power during the Industrial Revolution. Steam engines like Thomas Newcomen’s atmospheric engine and James Watt’s improvements were able to provide much more consistent rotary power than water wheels which were dependent on the fluctuating flow rates of streams (Source). The development of water turbines like Francis turbines and Pelton wheels in the late 19th century also allowed hydro-mechanical power to be generated more efficiently than traditional water wheels (Source).

The widespread distribution of electricity in the early 20th century delivered the final blow to water wheels. Centralized power stations with steam turbines or hydroelectric dams could generate electricity much more efficiently. Transmission of this electricity over large distances via power grids made local water wheels obsolete (Source). The flexibility and convenience of electric motors led to the rapid decline of water wheels across all traditional applications like milling.

Modern Usage

Although water wheels are no longer used for large scale power applications, they are still sometimes used for small scale hydroelectric power generation. Small water wheels can be installed in flowing creeks or rivers to generate electricity on a small scale, such as for a remote homestead or farm. This type of small scale hydroelectric generation is low impact and takes advantage of the renewable energy from flowing waterways.

Water wheels are also popular for decorative purposes in gardens, parks, or along waterfront walkways. Their turning motion and sound of flowing water make them an appealing landscape feature. Decorative water wheels come in various sizes and styles, from small backyard water wheels to large wheels along public waterways.

Lastly, water wheels may be used for educational purposes to demonstrate the mechanics of converting kinetic water energy into rotational energy. Water wheels are a useful hands-on learning tool to explore topics like physics, energy conversion, and engineering. Replica water wheels may be found at living history museums, science centers, or in school science labs.[1]

Advantages

Water wheels have several key advantages that have made them an appealing source of power for centuries. First, they are a renewable energy source, relying on the natural kinetic energy of flowing water. As long as there is a steady flow of water, a water wheel can keep turning and producing power indefinitely without needing any outside fuel source (Source 1).

Second, water wheels have a relatively simple construction and design. The materials needed, such as wood and metal, are readily available. The technology is uncomplicated compared to steam or gasoline engines. This makes water wheels easy to build and repair locally (Source 1).

Finally, water wheels require relatively low maintenance once constructed. They have few moving parts that require upkeep. As long as the water source remains consistent, a water wheel can run unattended for long periods. This is a major advantage over engines reliant on fuel sources (Source 1).

Disadvantages

While water wheels have some advantages, they also have some notable disadvantages that have limited their use in modern times. Three key disadvantages are:

Inconsistent Power

The amount of power generated by a water wheel depends on the flow rate and volume of the water source. Rivers and streams often have variable flow rates based on seasonal rainfall and weather events. This inconsistency in water flow leads to fluctuations in the power output of water wheels (source). Modern power grids require steady and reliable power generation.

Limited Sites

Water wheels require specific sites with fast-flowing water sources to operate efficiently. Suitable sites are limited geographically, restricting where water wheels can be utilized (source). This limits the scalability of water wheel power.

Weather Dependence

As water wheels rely on flowing water to generate power, they are heavily dependent on regional weather and climate conditions. Droughts and freezes can severely impact the operation and power output of a water wheel (source). This vulnerability to weather extremes is a downside compared to fossil fuel and nuclear power plants.

Conclusion

In summary, water wheels were an effective early form of hydropower that provided mechanical energy for milling and other industrial applications for centuries. Their simplicity and ability to harness the power of flowing water made them a practical solution before the advent of more advanced hydro turbines. While they have become obsolete in most parts of the world, water wheels still fill niche applications where low-tech solutions are preferred.

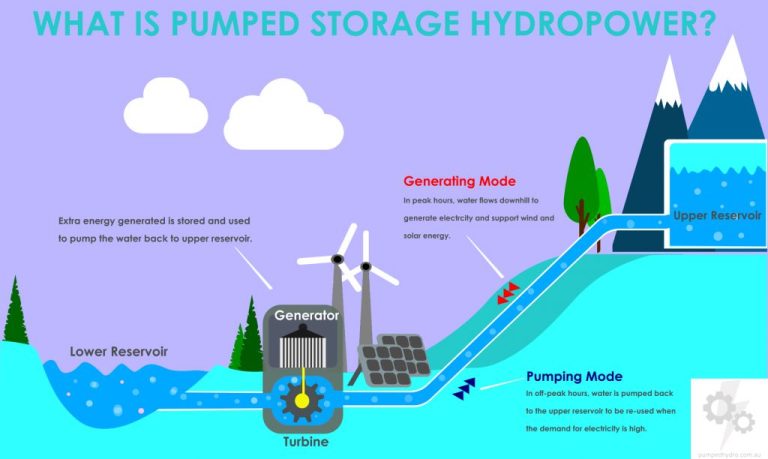

Looking to the future, there is renewed interest in water wheels as a sustainable energy source. Advances in generator technology and design modifications like the slow-rotation SmartHydro water wheel have improved efficiency. Water wheels with integrated electric generators can now produce useful amounts of electricity to supplement other renewable sources. Though they cannot compete with large hydro dams, water wheels have potential to generate green power from small streams and irrigation canals. Their simplicity, low environmental impact, and ability to operate without dams or impoundments makes water wheels an attractive option for localized renewable energy. With some modern improvements, the ancient water wheel may still have a role to play in our energy future.