How Does Hydropower Get To Your House?

Hydropower Basics

Hydropower is a renewable energy source that utilizes the natural flow of water to generate electricity. There are two main types of hydropower plants:

- Run-of-river plants channel a portion of a river’s water through a canal to spin turbines. These plants do not require dams and have a minimal environmental impact.

- Reservoir plants impound water behind a dam to store potential energy. The stored water can be released as needed to drive turbines and generate electricity.

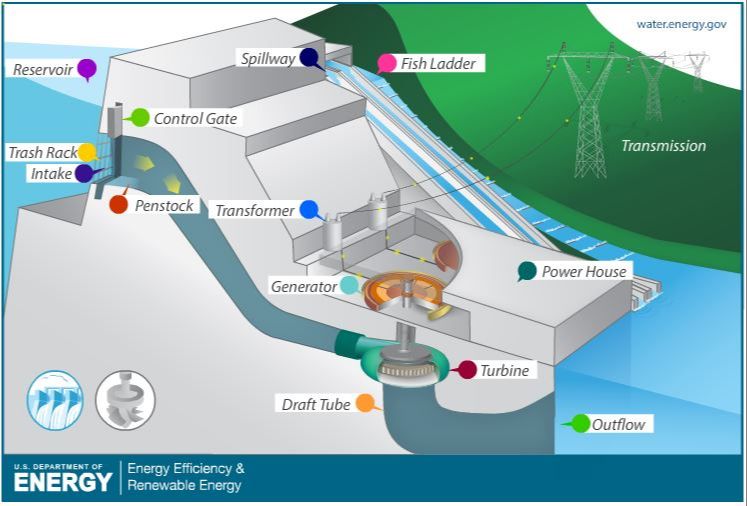

At hydropower plants, the force of flowing or falling water spins a turbine connected to a generator to produce electricity. The amount of available energy in moving water is determined by its flow rate and fall in elevation. Fast moving water or steep drops in elevation produce more kinetic energy which is converted into electrical energy by the plant.

Hydropower is considered a renewable energy since it relies on the water cycle. As long as adequate water flow is maintained, hydropower can produce electricity indefinitely.

Sources:

https://www.iea.org/energy-system/renewables/hydroelectricity

https://ourworldindata.org/grapher/hydropower-consumption

Building a Dam

Building a dam is a massive undertaking that requires extensive planning and preparation. The first step is selecting an appropriate site for the dam. Some key factors in site selection include bedrock composition, availability of construction materials nearby, terrain contours, and distance from energy transmission infrastructure. Many of the largest dams in the United States are built in narrow gorges or canyons surrounded by bedrock, which provides a solid foundation. For example, Oroville Dam, the tallest dam in the U.S. at 770 feet, sits on solid bedrock in a steep canyon along the Feather River in California (Wikipedia).

Once a site is selected, the construction process begins. This involves excavating down to bedrock, diverting rivers, preparing foundation rock surfaces, and pouring massive amounts of concrete. The Hoover Dam, built in the 1930s, used over 3.25 million cubic yards of concrete. After the dam structure is completed, spillway tunnels, intake structures, and hydropower facilities are added. The final steps include adding generators, transformers, transmission lines to deliver the electricity, and restoration of surrounding lands. In total, building a major dam often takes 5 to 10 years or longer.

Turbines

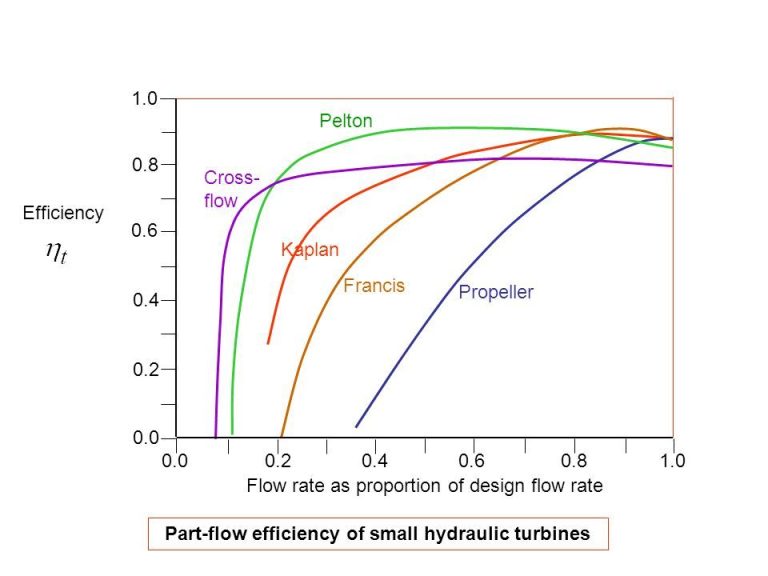

Water turbines are rotary machines that convert the kinetic and potential energy of water into mechanical work to generate electricity. There are two main types of turbines used in hydropower plants:1

Impulse Turbines – These turbines use the velocity of water to move the turbine blades. Water passes through nozzles which direct it onto the blades of the turbine runner, causing them to spin. Common types of impulse turbines include Pelton and Turgo turbines. They are suitable for high head sites.

Reaction Turbines – These turbines generate power by the combined action of pressure and moving water. The runner blades are fully immersed in water, which applies pressure to the blades to drive the turbine. Common reaction turbines include Kaplan, Francis and Propeller turbines. They are suitable for low head power sites.

Hydropower turbines convert the energy of flowing water into rotational energy to turn an electrical generator and produce electricity. The kinetic energy of the moving water impacts and turns the large blades of a turbine runner, which spins a shaft connected to a generator to produce electrical power.2

Generators

Generators are a crucial component in hydropower plants. Their purpose is to convert the mechanical energy from the spinning turbine into electrical energy (U.S. Department of Energy, n.d.). This happens through electromagnetic induction – when the turbine causes the rotor inside the generator to spin, it rotates within a magnetic field, producing an electric current (Andritz AG, n.d.).

There are several types of generators used in hydropower plants, but synchronous generators are most common. They operate at the same frequency as the power grid and rotate at a constant speed as the turbine spins (Andritz AG, n.d.). The generators are enormous, with capacities over 1,000 megawatts in large-scale facilities (U.S. Department of Energy, n.d.). Overall, generators are critical components that enable hydropower plants to harness the kinetic energy of moving water and convert it into usable electricity.

Transformers

Transformers play a critical role in the transmission of electricity from power plants to homes and businesses. They are used to increase (‘step up’) and decrease (‘step down’) voltage along the transmission and distribution system.

At power plants, generators produce electricity at low voltage levels around 10-25kV. To transmit this power over long distances efficiently, the voltage needs to be stepped up to high transmission voltages of 115kV or above using step-up transformers. According to Wikipedia, transmission-level voltages are usually 110 kV and above.

The higher voltages enable the power to be transmitted with lower electric current, which reduces energy losses over distances. Step-down transformers are then used at substations along the network to reduce the voltage for distribution to customers. The distribution voltages range from 2kV to about 35kV. Finally, pole-mounted transformers outside homes and buildings further step down the voltage to standard 120/240V for use.

Transmission Lines

The U.S. electric transmission network consists of about 700,000 circuit miles of lines. Most of the lines operate using alternating current at voltages from 115 kV to 765 kV, and are strung along towers and poles made of steel or wood. According to a U.S. Energy Information Administration study, two-thirds of transmission lines are high voltage over 230 kV (citing https://www.eia.gov/todayinenergy/detail.php?id=36393). Constructing these towers and lines requires careful routing and planning across long distances, sourcing of materials for the towers and lines themselves, and skilled crews to install equipment safely to stringent standards.

Transmission towers play a key role as they have to support heavy conductors and provide adequate ground clearance. Towers use various structural designs tailored to factors such as terrain, cost, weather impact, and conductor weight and tension. Most common transmission tower types include lattice towers with steel corner supports and a central steel pole, or guyed-V towers braced by guy wires. Towers are spaced according to terrain and voltage. Steel and concrete are typical construction materials.

The conductors themselves, made of materials like aluminum and copper, transmit the electricity at very high voltages. Multiple conductors are strung between towers for each electrical circuit. Design regards varied factors like minimizing resistance and the corona effect. Inspection and maintenance of transmission lines is vital throughout their lifecycle, through climbing, aerial lifts, and drones.

Substations

Substations play a vital role in the power grid system by lowering the voltage of electricity coming from power plants before it gets distributed to homes and businesses. There are over 79,000 transmission substations across the United States according to the Department of Homeland Security’s Sector Spotlight on Electricity Substation Physical Security report [1].

Electricity is generated at power plants at very high voltages. This voltage needs to be lowered or “stepped down” before it can be safely distributed to end users. Substations contain transformers to reduce electricity from transmission level voltages of 138,000-765,000 volts down to distribution voltages of 2,400-34,500 volts [2]. Substations act as the transition point between the high voltage transmission system and lower voltage distribution system.

Without substations to lower these voltages, electricity would be too dangerous to deliver directly to homes and businesses. Substations are a crucial intermediary that make widespread electricity distribution possible.

Distribution Lines

Local distribution lines carry electricity at lower voltages, typically under 50 kilovolts, from local substations to homes and businesses. According to the U.S. Energy Information Administration, there are approximately 6.5 million miles of distribution lines across the United States.1 These lines are usually supported by utility poles and run along streets overhead or underground.

The typical voltage of residential distribution lines is 120V in the U.S. and 240V in most other countries.2 Local transformers mounted on poles or placed in underground vaults reduce the voltage from subtransmission levels to utilization levels for residential and commercial customers.

Local distribution systems are connected in loops and networks to provide redundant paths so that power can be rerouted in case a line segment fails. Utilities monitor the voltages and loading on distribution lines and can isolate problems, switch loads, and reroute power to balance the system.

Smart Meters

Smart meters are digital meters that utilities install at homes and businesses to provide two-way communication between the customer and the utility. They allow utilities to remotely collect meter readings, monitor voltage and outage information, and more. Smart meters replaced traditional mechanical meters that required manual meter reading and could only track total energy usage (source).

Smart meters communicate wirelessly using various technologies like cellular, radio frequency mesh networks, Wi-Fi, and power line communication. This allows utilities to get frequent energy usage data, often multiple times per day. The increased data helps utilities better understand energy usage patterns and respond to outages faster (source).

The main purposes of smart meters are:

- Allow remote reading of meters without needing manual reads

- Provide detailed energy usage data to utilities and customers

- Enable time-based rates and programs like demand response

- Quickly detect and respond to outages

As of 2022, about 72% of U.S. electric meters were smart meters, with continued growth expected in coming years (source).

Your House

Power enters your house through the electric meter and service panel, also known as the breaker box. The electric panel contains circuit breakers that distribute electricity throughout the house. Circuit breakers can shut off power to individual circuits if they become overloaded.

The average American household consumes around 10,600 kilowatt-hours (kWh) of electricity per year. This would equate to around 29 kWh per day for the average home in the United States (EIA).

Electricity powers lights, appliances, electronics and more once it enters your home. Standard 120-volt circuits serve most household needs, while large appliances like electric dryers, air conditioners and electric ranges require 240-volt circuits.