How Does An Ac Generator Produce Electricity?

An AC generator, also known as an alternator, is a device that converts mechanical energy into alternating current (AC) electrical energy. AC electricity is the most common type of electricity used in homes and businesses. It is called alternating current because it alternates between a positive and negative charge many times per second. This contrasts with direct current (DC) electricity, which only flows in one direction.

Generators work based on the principle of electromagnetic induction. When magnets spin near wire coils, they induce a voltage across the coils. The magnets inside an AC generator spin next to stationary coils of wire to produce a sinusoidal AC voltage. This voltage can then be used to power electrical devices and equipment. By connecting an AC generator to a turbine or engine, the mechanical rotation can be converted into usable electricity.

AC Generator Components

The main components of an AC generator are:

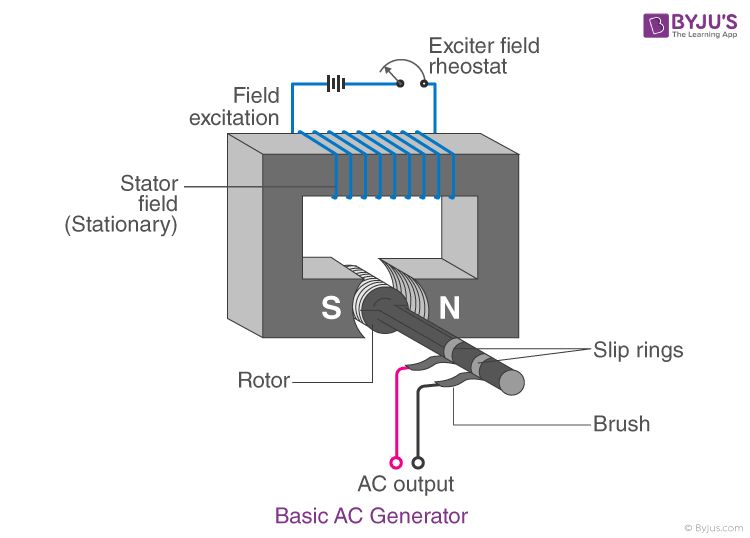

- Stator – The stator is the stationary part of the generator. It contains a set of electrical conductors wound in coils around an iron core. These conductors are called armature windings.

- Rotor – The rotor is the rotating part of the generator. It contains another set of electrical conductors wound in coils around an iron core attached to a shaft. The rotor spins inside the stator to produce electricity.

- Slip rings – The slip rings are copper or brass rings mounted on the rotor shaft that allow current to be drawn from the rotating rotor. The rotor coils are connected internally to the slip rings.

- Brushes – The brushes are copper or graphite contacts that press against the slip rings to conduct current from the rotating rotor. The brushes connect the rotor coils to the external load circuit.

As the rotor spins inside the stator, the moving magnetic field induces a voltage in the stator windings. The current is conducted through the slip rings and brushes to power the external load.

Electromagnetic Induction

Electromagnetic induction is the process that allows an AC generator to produce electricity. It involves a conductor, such as a wire coil, moving through a magnetic field. This motion of the conductor through the magnetic field induces a voltage across the ends of the conductor. The induced voltage causes electrons in the conductor to move and generate current.

Here’s a more detailed explanation of how it works in an AC generator:

Inside the generator, there are magnets and a coil of wire called the armature. The armature rotates within the magnetic field created by the magnets. As it rotates, the magnetic field around the armature changes. This changing magnetic field induces a voltage in the coil of the armature. The faster the armature rotates and the magnetic field changes, the larger the voltage that gets induced.

The induced voltage is called the electromotive force (EMF). This EMF along with the winding resistance and inductance of the armature produce an alternating current in the coil as it rotates. So the basic principle is that the motion of the armature and changing magnetic fields produce the alternating voltage that leads to AC current generation.

AC vs DC Current

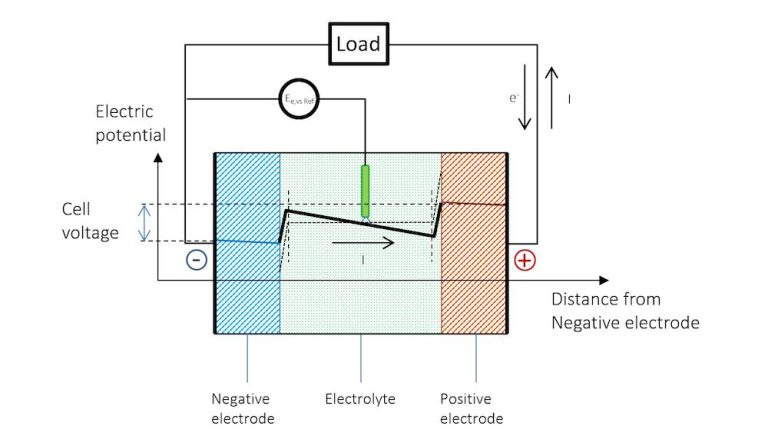

AC stands for alternating current, while DC stands for direct current. The key difference between AC and DC is that the current in AC alternates direction periodically, while it flows in one direction constantly in DC.

In AC, the voltage rises from zero to a maximum in one direction, drops back through zero to a maximum in the other direction, then repeats this cycle continuously. The voltage and current alternate at a frequency that is measured in Hertz (Hz), typically 50 or 60 Hz for power systems.

In contrast, DC maintains a constant voltage or current that flows in one direction only. Batteries are a common example of a DC power source. The current flows from the positive to the negative terminal to power devices.

AC is the most common type of electricity used today because it allows efficient transmission over long distances. The alternating nature of AC current can be increased or decreased easily using a transformer. This allows efficient power transmission at extremely high voltages and lower currents to reduce losses.

Generator Rotation

The rotating magnetic field is generated by the rotor which spins inside the stator. The rotor is made up of a shaft that connects to the turbine and has electromagnetic field coils wound around it. As the turbine spins the rotor, it rotates inside the stator windings.

This rotation causes the magnetic field from the rotor coils to sweep across the stationary stator windings. As the magnetic field crosses the windings in the stator, it induces an alternating electric current to flow. The speed at which the rotor spins determines the frequency of the alternating current produced.

So in summary, the physical rotation of the electromagnetic rotor inside the stator windings causes the magnetic field to alternate back and forth across the stator. This changing magnetic flux induces an alternating EMF (electromotive force) or voltage according to Faraday’s Law of Electromagnetic Induction. The result is AC electricity generation from the simple rotational motion.

Excitation System

The excitation system is a critical component of an AC generator that provides a magnetic field to the rotor. Its purpose is to induce voltage in the stator windings for power generation. The excitation system consists of an exciter, voltage regulators, brushes, and slip rings.

The exciter is an auxiliary generator that generates DC current through its windings to energize the rotor. This DC current produces the magnetic field in the rotor poles that is rotated at synchronous speed along with the rotor. As the magnetic field rotates and cuts across the stator windings, it induces an alternating voltage based on the principles of electromagnetic induction.

Voltage regulators control the amount of DC current supplied to the rotor by the exciter. This allows the generator output voltage to be adjusted to match the required system voltage. The DC current is transferred from the exciter to the rotor windings via brushes and slip rings. The purpose of the excitation system is therefore to produce the necessary magnetic field for voltage induction in the AC generator.

Voltage Regulation

Voltage regulation in an AC generator is the process of controlling the output voltage, so it remains within acceptable limits despite changes in load current. There are two main methods for regulating voltage in generators:

AVR (Automatic Voltage Regulator)

The AVR is an electronic circuit that senses the generator output voltage and compares it to a set reference. If the output voltage drifts from the reference, the AVR sends a signal to adjust the generator excitation current to bring the voltage back to the desired level. The AVR provides continuous fine control over voltage.

Manual Voltage Control

Larger generators have a manual voltage adjust rheostat that allows the operator to directly control the exciter field current. The operator monitors voltage instruments and manually adjusts the rheostat as needed to maintain voltage within limits. Manual control is slower and less precise than AVR.

Proper voltage regulation maintains AC output within 5% of the nominal value under changing load conditions. Good voltage control prevents damage to connected equipment and ensures optimal power quality for the electrical system.

Power Output

The power output of an AC generator depends on several factors:

Generator speed – The faster the generator spins, the higher the frequency and voltage it produces, resulting in more power output. Most generators operate at a synchronous speed of 3000 or 1800 rpm.

Number of poles – Adding more poles to a generator allows it to produce the same voltage at a lower rotational speed. However, more poles generally mean more winding copper and iron, increasing size and cost.

Stator and rotor design – Larger machines with more coil windings and stronger magnets or electromagnets can induce higher voltage and handle more current, increasing power capacity.

Prime mover – The input mechanical power from the prime mover (turbine, engine) limits generator power output. More powerful prime movers allow generators to convert more mechanical energy into electrical energy.

Cooling and efficiency – Better cooling systems allow generators to run at higher ratings without overheating. Higher efficiency reduces losses, allowing more input power to be converted into electricity.

Power factor – Generators produce more usable power at higher power factors. Power factor can be optimized by controlling generator excitation, adding power factor correction equipment, and designing efficient generators.

Applications of AC Generators

AC generators have many important applications in modern society. Here are some examples of how AC generators are commonly used:

Power Plants

Electricity generation at power plants relies heavily on AC generators. Thermal power plants use steam turbines connected to AC generators to produce electricity from heat sources like coal, natural gas, or nuclear fission.

Wind Turbines

Most utility-scale wind turbines operate using an AC generator. The rotational kinetic energy from the turbine spins a shaft connected to the generator to produce AC electricity.

Hydroelectric Plants

At hydroelectric dams, falling water spins hydraulic turbines which then drive AC generators to convert the mechanical rotation into electrical energy.

Gas Turbines

Jet engines and gas turbines are fitted with small AC generators to convert excess rotational energy into supplementary electrical power.

Diesel Generators

Diesel generators have diesel engines mechanically coupled to AC generators sets. This makes them portable sources of AC electrical power.

Automotive Alternators

In automobiles, an AC generator called an alternator charges the battery and powers the electrical system while the engine is running.

Conclusion

In summary, AC generators are an incredibly important technology that we rely on to produce virtually all of our electricity. By rotating magnets past coils of wire, AC generators are able to produce alternating current electricity on a large scale. This AC electricity can then be transmitted long distances and stepped up or down in voltage as needed, making it the ideal form of electricity for power grids.

Without AC generators, we would not have access to affordable and reliable electricity like we do today. Their ability to efficiently produce large amounts of electricity drove the electrification of cities and homes. AC generators enabled incredible advances for humanity by powering technology, appliances, infrastructure and more. Our modern society owes a great deal to the AC generator.

While the basic principles of electromagnetic induction in AC generators were discovered over a century ago, engineers continue to improve generator technology today. More efficient designs, smarter control systems, and new materials are pushing the capabilities of AC generators further. However, the fundamental working principles remain the same, with generators continuing to produce clean electricity from the rotational energy of turbines.