How Does A Generator Work Step By Step?

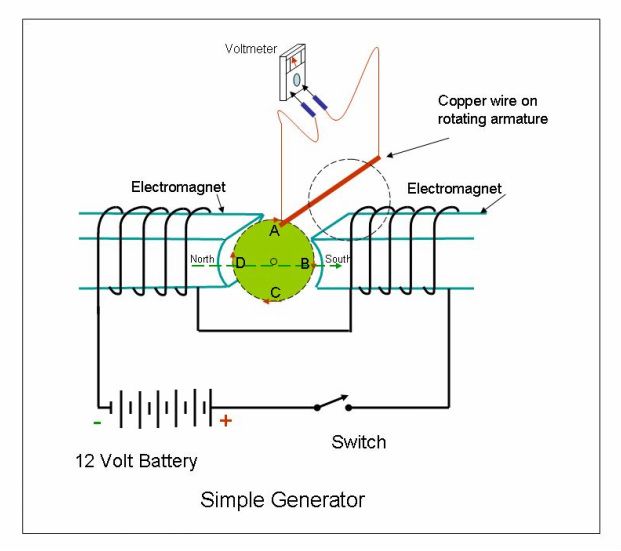

A generator is a machine that converts mechanical energy into electrical energy. It works by using an engine to spin a rotor inside a magnetic field, which produces a flow of electrons or electricity.

The basic principle behind how a generator works is electromagnetic induction. When the rotor spins, it causes the magnetic field around it to move. This change in magnetic flux induces a voltage on the generator’s armature or stator coils. The generator’s voltage regulator ensures this electricity is delivered at a constant voltage.

There are several common types of generators:

- Portable generators – Smaller generators for home or RV use

- Standby generators – Permanently installed at a location to provide backup power

- Diesel generators – Larger generators often used at construction sites

- Wind turbines – Generate power from wind energy

- Hydroelectric generators – Generate power from moving water

Main Components

Generators have several main components that work together to produce electricity:

Engine

The engine is usually a gasoline, diesel, propane or natural gas internal combustion engine that provides the power to turn the alternator. Smaller portable generators often use single-cylinder engines while larger standby generators can have multiple cylinders.

Alternator

The alternator uses the mechanical power from the turning engine to generate electrical power. It contains magnets that rotate around wire windings to induce an alternating current that is then converted to direct current for use.

Fuel System

The fuel system delivers gasoline, diesel, natural gas or propane to the engine. It consists of a fuel tank, fuel lines, carburetor or fuel injectors, and fuel pump.

Voltage Regulator

The voltage regulator controls the output voltage from the alternator to maintain the correct voltage and prevent fluctuations that could damage appliances.

Cooling System

The cooling system circulates water or air to prevent the engine and alternator from overheating. It includes a radiator, water pump, cooling fans, and connecting hoses.

Exhaust System

The exhaust system expels the exhaust gases created by the combustion in the engine and consists of an exhaust manifold, catalytic converter, muffler and exhaust pipe.

How Generators Produce Electricity

Generators produce electricity through a process called electromagnetic induction. At the heart of the generator is an engine that turns an alternator. The alternator contains electromagnets that rotate rapidly around a set of stationary wire coils, or windings.

As the electromagnets rotate past the wire windings, they create a change in the magnetic field around the coils. This change in magnetic field induces a voltage and electrical current in the coil windings. The induced voltage and current constitute the electricity that is generated.

The faster the alternator’s electromagnets spin, the more times per second the magnetic field changes around the coils, which increases the rate of electrical current production. Most generators optimize their engine and alternator sizes so they can most efficiently produce the standard household alternating current of 60 Hz at 120 and 240 Volts.

Voltage Regulation

The voltage regulator is a crucial component that controls the voltage output of the generator. As the engine speed changes when electrical loads are applied or removed, the voltage regulator maintains a steady voltage output usually around 120V in North America or 230V in Europe.

Without a voltage regulator, the voltage output would fluctuate significantly as engine speed changes. Fluctuating voltage can damage equipment and appliances connected to the generator.

The voltage regulator monitors the output voltage and makes automatic adjustments to maintain the desired voltage level. It does this by controlling the excitation current sent to the rotor windings of the generator based on the detected voltage output.

If the voltage starts to drop below the desired level, the regulator will increase the excitation current, which increases the magnetic field strength to raise the voltage. If the voltage rises too high, it will reduce the excitation current to lower the voltage.

The voltage regulator ensures quality, steady power is provided to connected loads even as engine speed varies when electrical loads are applied or removed. This steady voltage output is critical for safe generator operation.

Fuel System

The fuel system is responsible for delivering clean fuel to the engine at the proper pressure and volume for optimal performance. It consists of several key components:

Fuel Tank

The fuel tank stores the gasoline or diesel that powers the generator. It is made of durable materials like steel or plastic to prevent leaks or damage. The tank includes a fuel level sensor to indicate how much fuel remains.

Carburetor or Fuel Injector

The carburetor or fuel injector mixes air with the fuel to prepare the combustion mixture. Carburetors use ventilation pressure differences while fuel injectors actively spray fuel. Both achieve the proper air/fuel ratio for efficient burning.

Fuel Filter

Fuel filters remove contaminants like dirt, rust, and water from the fuel before it reaches the engine. This protects the carburetor or injectors from clogging or wear. Filters are placed in the fuel line and require periodic replacement.

Fuel Pump

The fuel pump delivers fuel from the tank to the carburetor or injectors under pressure. This ensures a reliable supply of fuel. Mechanical pumps are driven by the crankshaft while electric pumps operate independently. The pump must provide the required fuel volume and pressure.

Cooling System

The cooling system is critical for keeping the generator’s engine from overheating. It consists of several main components:

- Radiator – The radiator is made up of many small tubes and fins and acts like a heat exchanger. As hot coolant from the engine flows through it, the fins help dissipate the heat into the air stream from the cooling fans.

- Cooling fans – Most generators have electric cooling fans that pull air through the radiator to provide cooling airflow when the engine is running.

- Coolant – The coolant (typically a mixture of water and antifreeze) circulates through the engine block and cylinder head, absorbing heat. It then flows through hoses into the radiator to be cooled before circulating back to the engine.

This circulation of coolant through the radiator and engine is vital for carrying away the waste heat produced by the engine during operation. If the cooling system fails and the engine overheats, it can cause major damage or even engine failure. Therefore, it’s important to make sure the cooling fans are working and that the coolant level is maintained.

Connecting and Starting Generator

Properly connecting and starting your generator is crucial for safe operation. Here are some key steps:

Make sure the generator is grounded – connect a grounding rod or wire to prevent electric shock. Improper grounding can put you at risk of electrocution if there are faults in the generator’s wiring.

Check engine oil and fuel levels before starting. Make sure to fill the fuel tank and check that oil is at the proper level to prevent engine damage. Running on low oil can cause catastrophic failure.

If equipped with a carbureted engine, set the choke lever to start position. This provides a richer air-fuel mixture to aid starting. Remember to gradually open the choke once the engine warms up.

Start the engine either by turning the ignition key or pulling the starter cord. Let the generator run for a few minutes before connecting appliances or tools. Check for any leakage, smoke or abnormal noises when running.

With the engine started and running smoothly with no issues, you can now begin plugging in devices and using the power output. Just be sure not to overload the generator’s rated wattage capacity.

Voltage and Power Output

A key factor in running a generator properly is matching its wattage capacity to the load or devices you plan to power. Determine the starting and running wattage requirements of the items you will connect, such as appliances, tools, and electronics. Select a generator with enough wattage to exceed the startup surge and continuous load demand.

Most generators supply dual 120V household power, which determines the wattage available. For example, a typical 6000W (6kW) portable generator can supply about 50A at 120V. Check the generator’s rated and maximum amperage to avoid overloading. Exceeding the continuous wattage rating can overload and damage the generator.

It’s also important to monitor the voltage while running your generator. Voltage should be as close to 120V as possible for optimal performance. If voltage is low, it can damage appliances and electronics. If voltage is high, it can destroy insulation and motors. Use a multimeter to test voltage at the generator’s power outlets. Consult your owner’s manual if voltage is outside an acceptable range (usually +/- 10% of 120V).

By matching generator capacity to the load and monitoring voltage, you can safely and efficiently utilize the power from your generator.

Maintenance

Regular maintenance is critical for keeping generators running safely and efficiently. Here are some key maintenance tasks:

Oil and Filter Changes

Change the oil and oil filter according to the manufacturer’s recommendations. This is typically after the first 20 hours of use, then every 100-200 hours or once yearly. Use the type and weight of oil specified in the owner’s manual.

Cleaning Air Filter

Clean the air filter regularly to remove debris and dirt. A clogged air filter can cause poor engine performance. Clean foam filters by washing with mild detergent and allow to fully air dry. Replace paper filters as needed.

Replacing Spark Plugs

Replace spark plugs about every 100 hours of use or yearly. Use the spark plug type specified by the manufacturer. Check that the gap is correct with a feeler gauge and adjust as needed.

Inspecting and Replacing Brushes

For generators with brushed alternators, inspect the brushes about every 300 hours of use. Replace worn brushes to ensure proper electrical contact and output. Follow the manufacturer’s instructions for brush replacement.

Safety Tips

When using a generator, it’s important to follow key safety tips to prevent injuries, fires, or equipment damage:

Proper grounding – Always ensure the generator is properly grounded to prevent electric shocks. Connect the generator’s grounding rod or connect to a grounded receptacle.

Avoid overloading – Do not overload the generator by plugging in more appliances than it can handle. Check the wattage rating and do not exceed it.

Operate in well-ventilated area – Only run a generator outside in an open area. The exhaust contains dangerous carbon monoxide.

Regular maintenance – Follow the maintenance schedule and check components like oil, filters, battery, etc. A well-maintained generator is safer.

Fuel safety – Use proper fuel storage containers. Refuel with the generator off and let it cool before adding fuel. Don’t overfill the tank.