How Do You Generate Electricity With A Kite?

Airborne wind energy refers to the use of tethered flying devices to harness wind power at higher altitudes than conventional wind turbines. (Benefits)

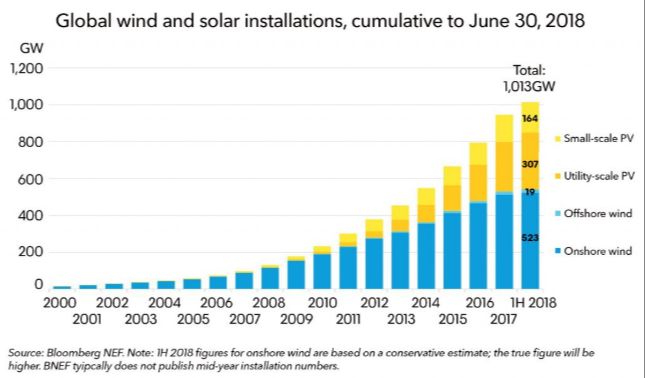

The concept dates back to the 1970s, but has seen major advances in the past decade due to improvements in materials, automation, and control systems. Airborne wind offers several advantages over tower-mounted turbines, including access to faster and more consistent winds at higher altitudes, lower costs from ground-based generation and installation, and the ability to be quickly repositioned. (Wind energy ready for takeoff)

By utilizing high-altitude wind that is generally much stronger and steady compared to ground level, airborne systems can potentially produce more energy for less cost than traditional wind power. Harnessing these high altitude winds is especially valuable in areas without strong ground-level winds. The airborne units can also be made to be portable and require minimal land space. Overall, airborne wind energy aims to provide a new option for scalable and low-impact renewable energy generation. (Benefits)

How Kite Electricity Generation Works

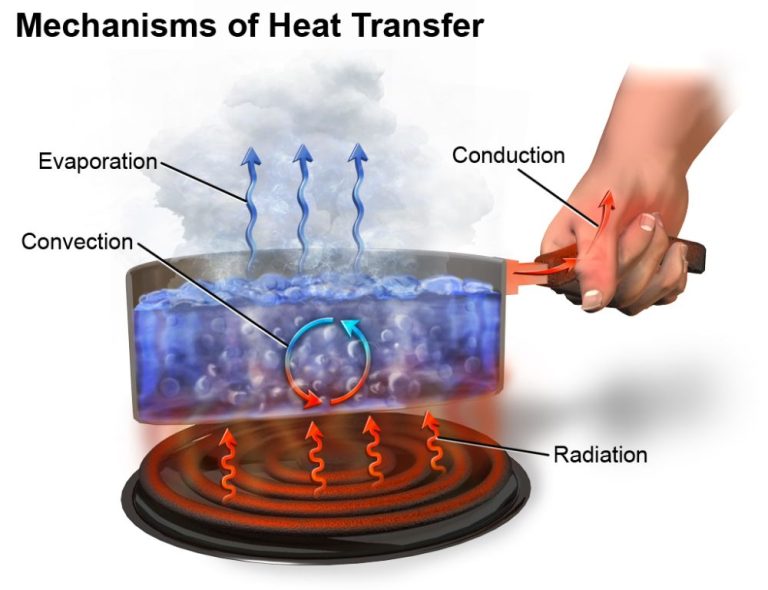

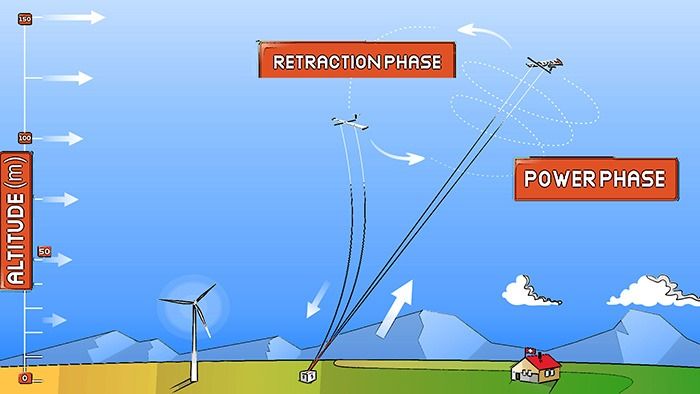

Kite electricity generation involves harnessing the kinetic energy of wind and converting it into electrical power. The basic principle relies on having a kite or other aerial device lifted and controlled by the wind in order to pull on a tether connected to a ground-based generator.

As the kite flies patterns through the sky, it continues to generate an aerodynamic lifting force. This force pulls on the tether, creating tension that can rotate a shaft or drum to spin an electrical generator. So the kinetic energy of the wind gets converted first into mechanical energy in the rotating shaft, and then into electrical energy by the generator.

Most designs utilize a flexible wing or parafoil kite that is lighter and more controllable than a rigid design. The kite is flown in crosswind patterns to maximize the traction force. Some systems use automated control systems and sensors to optimize the flight patterns for power generation depending on wind conditions.

Kite electricity can be generated with either a tethered system where the kite is attached to a fixed reel on the ground, or with an on-board generator where the kite flies freely and transmits power back to the ground through its tether. Tethered systems allow for a central generator that can be larger and more efficient.

Kite Designs

A key consideration in electricity generation from kites is the kite design and engineering. Researchers have explored various innovative kite types and shapes to optimize aerodynamics and efficiency. Early designs were often variations of traditional single-line delta or parafoil kites (Smithsonianmag.com).

More recent kite designs utilize rigid wings with airfoil designs to maximize lift and controllability. Makani’s M600 kite features a distinctive rigid wing design comprising of eight propeller-powered rotors encircling a large central rotor. The rotors allow the kite to take off and land vertically like a helicopter (Makanipower.com).

Materials are also an important factor in kite design. Lightweight, high-strength materials like ripstop nylon and carbon fiber help minimize weight while providing the necessary durability to withstand high winds and stresses of operation. KitePower’s 100kW system utilizes a durable nylon fabric design (Kitepower.eu).

Ongoing research and development continues to optimize aerodynamics, stability, maneuverability and durability to improve the viability of airborne wind energy using kites.

Generators and Equipment

The primary equipment needed for generating electricity with a kite includes the ground station, tether, control system, and generator.

The ground station houses the generator and winches that control the kite’s tether. It must withstand strong wind forces and allows the tether to unwind and rewind as the kite moves through the wind window. The tether connects to the control pod on the kite and is made of high-strength synthetic rope or cables. It transmits the pulling forces of the kite to the generator on the ground. Kitepower uses Dyneema for its tethers which is an ultra light and durable fiber.

The control system automatically steers the kite in optimal figure-8 patterns using sensors and actuators on the kite combined with algorithms. This maximizes power output as the kite moves through different wind speeds and directions. The generator converts the mechanical power generated by the kite into electrical power. Generators are designed to handle the rapid acceleration and deceleration involved in kite power systems.

A taser is sometimes employed which temporarily cuts the tether allowing the ground station to reel the tether back in with minimal force for the next cycle.

Potential Output and Efficiency

Kite electric generators have the potential for high energy output thanks to some key advantages. First, they can reach much greater heights than traditional wind turbines, usually around 500-1000 meters high compared to around 100-150 meters for turbines. As wind speeds increase with altitude, kites are able to access faster and more powerful winds. Studies show wind power increases by around 25% for every 100 meters of altitude gained (Ye, 2023).

Additionally, kite systems have a higher capacity factor than wind turbines. Capacity factor refers to the average power generated divided by the rated peak power. Wind turbines typically have capacity factors around 25-45%, while kite systems can achieve 50-70% (Harvard, 2015). This means kites can produce a more consistent, higher level of energy output.

Overall, kite electricity generators can potentially produce 2-3 times more energy per swept area compared to traditional horizontal axis wind turbines. Their ability to reach greater heights and consistency of power output gives them a substantial efficiency advantage.

Cost Analysis

The cost analysis of airborne wind energy systems is complex, as it involves evaluating the system and maintenance costs compared to the potential energy output. According to research from Delft University of Technology, the levelized cost of energy (LCOE) for airborne wind could be 7-15 cents per kWh by 2030 (1). This is higher than current costs for onshore wind (2-5 cents per kWh), but competitive with offshore wind (10-15 cents per kWh currently).

A key factor is the high capital and maintenance costs of the kites, tethers, and ground equipment. However, systems with multiple high-flying kites can capture stronger and more consistent winds, increasing capacity factors to over 50%. This improves the value proposition compared to conventional turbines. Researchers estimate a 600 kW system with 12 kites could produce electricity for 7-11 cents per kWh (2).

With continued engineering improvements, automated operation, and economies of scale, airborne wind costs could decrease further. But the complexity remains a barrier compared to simpler tower-based turbines. Overall, airborne wind is likely to remain a niche or hybrid approach best suited for remote, offshore, and mountainous areas where conventional wind is unavailable.

Challenges and Limitations

While kite energy technology shows promise, it also comes with some challenges and limitations that developers seek to overcome.

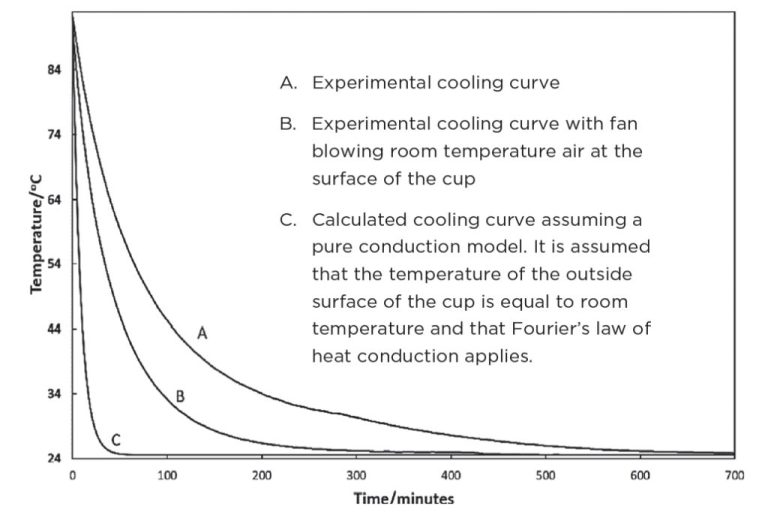

One major challenge is intermittency. Kite-generated electricity relies on having strong, steady winds blowing consistently. Wind speeds can fluctuate throughout the day and change direction abruptly. Times of low wind would mean less power generation. Intermittent power output from kites makes it difficult to integrate into the electricity grid compared to more stable baseload sources.

Weather impacts pose another challenge. Stormy weather with lightning or extreme winds could damage kite systems and require them to be grounded for safety reasons. This weather vulnerability can limit how often kites produce energy.

There are also technical difficulties to surmount. Keeping a large kite steady and aloft requires advanced control systems and materials engineering. Fatigue and wear on kite components from the high stresses of flight must be monitored and managed through maintenance. Consistent launching and landing of the kites adds complexity to operations.

While developers continue to refine designs and tackle these limitations, kite power’s variability and technical intricacy may constrain broader adoption. Sites with the most favorable wind conditions would see the greatest potential from kite systems.

Major Developers

Some of the leading companies developing airborne wind energy systems and prototypes include:

E-kite – Based in the Netherlands, this company has developed and tested an automated power kite system called the E-Kite. Their technology uses a single tether attached to a ground station generator.

Kitepower – This company from the Netherlands has created a two-kite system called the Rotorbird. Their technology aims to reduce costs by using flexible membrane kite wings.

Kite X – Based in the UK, this startup is developing a power kite system that uses automation and smart tethers to improve control and stability.

Some major projects include:

Makani – This project by Alphabet X developed an energy kite prototype called the M600. It was tested between 2006 and 2020 before the project ended.

KiteGen – An Italian company that designed and tested the KiteGen concept which used a ring generator design. Their prototype was tested between 2007-2010.

Future Outlook

The future looks bright for airborne wind energy systems. According to a report by Energy Monitor, installations of airborne wind systems are predicted to grow significantly after 2030 as the technology matures. By 2050, airborne wind could provide electricity to over 150 million households globally. Improvements in materials, automated control systems, machine learning algorithms and battery storage will all help drive down costs and improve efficiency of airborne wind systems. Companies like Ampyx Power and SkySails are leading innovation in the sector. Their next generation designs are aiming for capacity factors over 60% compared to 35% for conventional wind turbines. With no need for tall towers, gearboxes or foundations, airborne wind can unlock wind resources across more areas. Floating multi-megawatt scale airborne turbines operating at high altitude are expected by 2035. Airborne wind energy is finally ready for rapid growth.

Source: https://www.energymonitor.ai/tech/renewables/airborne-wind-energy-is-finally-ready-for-lift-off/

Conclusion

Generating electricity with kites is an innovative and promising renewable energy technology that can provide clean power at utility scale. The concept takes advantage of high altitude winds which are more consistent and stronger than those near ground level. Kites act like airborne wind turbines to harvest this wind energy and convert it into electricity through generators on the ground.

While still an emerging field, kite-based wind power has the potential to contribute meaningfully to the renewable energy mix. Advantages include low cost, mobility, and ability to reach stronger winds at higher altitudes. Kite generators can also be rapidly deployed and require less materials than conventional wind turbines. If technical challenges around controlling and operating the kites can be overcome, this technology may see significant growth and impact.

Overall, electricity generation with kites provides a novel way to tap into an abundant renewable resource. The technology can complement other renewables like solar and conventional wind power. With further development and commercialization, kite-based wind energy could play a role in building a more sustainable energy future.