How Do Photovoltaic Cells Work For Dummies?

What are photovoltaic cells?

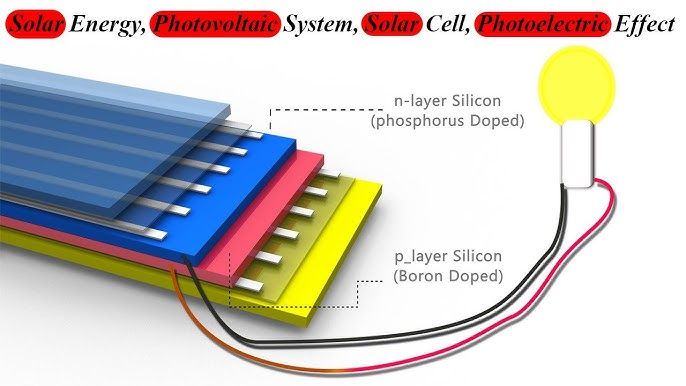

Photovoltaic cells, commonly known as solar cells, are devices that convert sunlight into electricity. The word “photovoltaic” comes from “photo,” meaning light, and “voltaic,” meaning electricity. Solar cells are made from semiconductor materials like silicon and work based on the photovoltaic effect. When sunlight hits the solar cell, photons from the sunlight are absorbed by the semiconductor material, causing electrons to be freed from their atoms. The flow of these electrons generates an electric current that can be captured and used as electricity.

The first solar cell was built in 1883 by Charles Fritts, who coated selenium with a thin layer of gold to form the junctions. However, the solar cells at the time were very inefficient with less than 1% efficiency. It wasn’t until the 1950s that practical solar cells suitable for applications were developed. The early market for solar panels was mainly for space applications to provide power aboard satellites. Over time, solar panel technology advanced, efficiency increased and costs declined, allowing PV systems to be used more widely on Earth for applications like powering homes, businesses and the utility grid.

Today, solar PV systems are one of the most common methods of generating renewable electricity. Solar panels can be found in a wide range of places, from small consumer devices, rooftop systems on homes and businesses, to large utility-scale solar farms with thousands of panels covering acres of land. With concerns about climate change and energy sustainability, solar PV offers a clean, renewable way to meet energy needs.

How do solar panels work?

Solar panels work through the photoelectric effect. When sunlight hits the solar cell, the photons are absorbed by the semiconducting material, usually silicon. This energizes the electrons and causes them to break free from their atoms. The solar cell contains both positively charged silicon and negatively charged phosphorous. As the freed electrons want to flow to the positively charged silicon, metal conductors on the cell provide a path for the electrons to flow through. This flow of electrons generates an electric current, which is direct current (DC).

The solar cell has three main components that enable this process. The photons strike the top layer, which is negatively charged. This cathode layer has electrons ready to mobilize. In the middle is the semiconducting silicon layer. When struck by photons, it frees up electrons. On the bottom is the positively charged anode layer which collects the electrons. As the anode and cathode are connected, it forms a circuit for electricity to flow.

In summary, solar cells use the photoelectric effect to convert sunlight into electrical energy. When photons hit the solar cell, they energize electrons which can then flow as electricity due to the cell’s internal electric field and the connection between the cathode and anode.

Types of Solar Cells

There are two main types of solar cells used in photovoltaic panels: silicon cells and thin-film cells.

Silicon Cells

The most common type of solar cell is made from silicon, a semiconductor material. Silicon cells can be either monocrystalline or polycrystalline.

Monocrystalline silicon cells are made from a single cylindrical silicon crystal. These cells have the highest efficiency rates, typically around 15-20%. However, they are more expensive to produce than other types of cells.

Polycrystalline silicon cells are made from fragments of silicon crystals that are melted and poured into molds. The random crystal fragments lead to lower efficiency rates of around 13-16%. But polycrystalline cells are cheaper to produce than monocrystalline cells.

Thin-Film Cells

Thin-film solar cells are made by depositing layers of photosensitive materials onto surfaces like glass, plastic or metal. Thin-film cells use less photosensitive material than silicon cells, making them cheaper to manufacture.

The efficiency rates of thin-film cells tend to be lower, around 7-13%. But they perform better than silicon cells in high temperatures. The most common thin-film materials are cadmium telluride (CdTe) and copper indium gallium selenide (CIGS).

Comparison of Efficiencies

In summary, monocrystalline silicon cells have the highest efficiency rates but are more expensive. Polycrystalline silicon is a cheaper option but less efficient. Thin-film cells are the cheapest to produce and work well in high heat, but their efficiency is lower than silicon.

Monocrystalline vs polycrystalline cells

There are two main types of solar photovoltaic cells – monocrystalline and polycrystalline. The main differences between them lie in the manufacturing process and performance.

Manufacturing process

Monocrystalline cells are made from a single cylindrical silicon crystal. To produce these cells, molten silicon is inserted into a squared mold and slowly cooled and solidified into an ingot. This process results in a homogeneous structure which enables electrons to flow more freely.

Polycrystalline cells are made from fragments of silicon crystals melted together. The silicon is melted down and poured into a square mold to cool and solidify. This results in a more heterogeneous structure with crystal boundaries that can impede electron flow.

Performance differences

The uniform structure of monocrystalline cells allows them to have a higher efficiency, typically around 15-20%. Polycrystalline cells tend to have a lower efficiency of around 13-16% due to increased resistance at crystal boundaries.

However, polycrystalline cells can be cheaper to produce than monocrystalline ones. The waste silicon fragments used in polycrystalline cells also gives them a characteristic blue color.

Costs

Monocrystalline panels tend to be more expensive than polycrystalline ones. A typical 250W monocrystalline panel may cost around $300 while a polycrystalline one of the same wattage would be around $250.

However, the increased efficiency of monocrystalline panels means you need fewer of them to achieve the same power output. So they can work out to be more cost effective in the long run.

How much sunlight is needed?

For photovoltaic cells to effectively generate electricity, they need direct exposure to sunlight. The amount of sunlight needed depends on the size and efficiency of the solar panel system.

Typically, solar panels require at least 4 hours of direct sunlight per day. More sunlight equals more energy production. In optimal conditions, 1 kW of solar panels requires about 100 square feet of direct sunlight.

The amount of sunlight available depends on location and weather conditions. Areas closest to the equator receive the most sunlight. Cloudy days and winter months with shorter daylight hours will produce less energy.

Latitude is a major factor determining sunlight strength. In the southern U.S., average annual sunlight ranges from 4.5 to 6.5 kWh/m2/day. Compare that to 2.5 to 3.5 kWh/m2/day in Alaska. Solar panels output more energy in sunnier climates.

To compensate for low sunlight, solar systems in less sunny climates need larger collector areas. Tracking systems that follow the sun’s path across the sky can also maximize sunlight capture.

Connecting solar panels together

To generate more power, solar panels can be connected together in series or parallel. Wiring solar panels together in series increases the voltage, while wiring in parallel increases the current. Here’s a closer look at each method:

Wiring solar panels in series

When solar panels are wired in series, the positive terminal of one panel is connected to the negative terminal of the next panel. This combines the voltages of each panel together for a total voltage equal to the sum of the individual panel voltages.

For example, connecting two 12V solar panels in series produces 24V. Connecting panels in series is useful when you need to step up the output voltage, such as for charging a 24V or 48V battery bank.

Wiring solar panels in parallel

When solar panels are wired in parallel, the positive terminals of each panel are connected together, and the negative terminals are connected together. This keeps the output voltage the same as each individual panel, but sums the current together.

For instance, connecting two 5A solar panels in parallel produces 10A total. Wiring in parallel boosts the total current to charge batteries faster or handle heavier electrical loads.

A solar array can include panels wired in both series and parallel. Large solar farms may have panels configured in long strings of series connections, with the strings then wired in parallel.

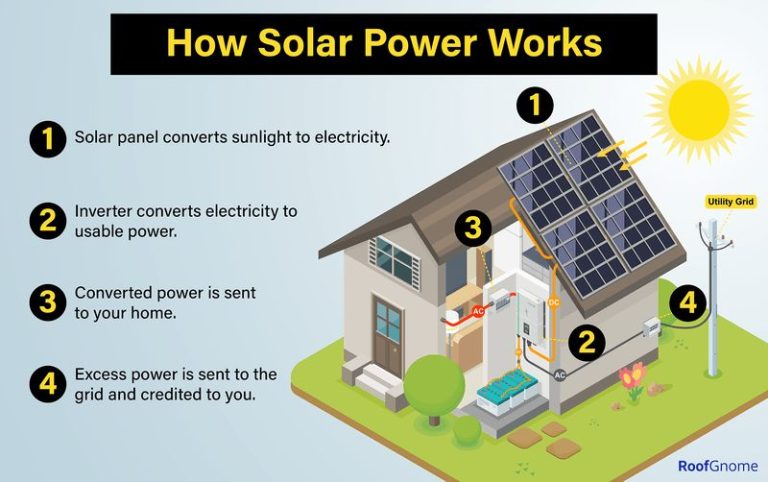

Inverters and Batteries

Solar panels produce direct current (DC) electricity, but our homes and the electric grid run on alternating current (AC) electricity. Inverters play a crucial role in converting the DC output of solar panels into usable AC electricity.

Inverters also regulate the voltage and current output of each solar panel. Most solar installations connect to the utility grid, allowing any excess solar energy to be sent back to the grid. For off-grid systems, batteries can store excess solar energy for use at night or on cloudy days. Batteries also help stabilize voltage and frequency levels.

There are many inverter options on the market, with differences in efficiency, warranty length, connectivity features, and whether they are single phase or three phase. Battery types include lead-acid, lithium-ion, and saltwater batteries, each with their own pros and cons.

Carefully selecting the right inverter and batteries for your solar system, and properly maintaining them, is key to ensuring optimal performance and return on investment.

Installation process

Installing a solar PV system on your home requires careful planning and execution. Here are the key steps involved in the installation process:

Permitting

Most local jurisdictions require you to obtain a permit before installing solar panels. When applying for a solar permit, you’ll need to submit a detailed plan showing the layout of the panels on your roof, electrical diagrams, and other specifications. The permitting office will review your application to ensure it meets all codes and standards.

Physical installation

Once the permit is approved, the solar installer will come to your home on the scheduled install date. They will start by making any necessary preparations to your roof, such as reinforcing the roof structure if needed. The solar panels are then mounted on racks secured to your roof. Wiring is run from the panels down to the inverters and electrical panel.

A typical solar panel installation takes anywhere from one to three days depending on the system size. The installer may also need to make return trips to finish hookups and inspections.

Inspection

After installation is complete, your local building department will come out to inspect the system. They will check that all wiring and components were properly installed according to code. The inspector will also test system functionality. Assuming everything passes inspection, your solar PV system can then be switched on and start generating clean energy!

It’s important to use qualified solar professionals who pull the required permits and schedule inspections. This helps ensure your system meets all safety and performance standards.

Costs and Incentives

The upfront cost of installing a residential solar system has dropped dramatically over the past decade, making solar energy much more affordable for homeowners. However, solar panels and additional equipment like inverters and batteries still represent a significant investment.

The total system cost for an average-sized 5kW solar array is $15,000-$25,000 before incentives. The exact price depends on the type and number of solar panels, mounting equipment, location, local labor costs, and other factors.

Fortunately, federal, state, and local incentives can reduce the net cost of a solar energy system by 50% or more. The biggest incentive is the federal solar tax credit, which allows homeowners to deduct 26% of installation costs from their federal taxes.

Many states and utilities also offer additional rebates, performance-based incentives, or Renewable Energy Credits (RECs) to make solar power even more cost-effective. Always check for current solar incentives in your area.

The payback period on a solar system varies widely but often ranges from 5-12 years after incentives. In the long run, solar panels can eliminate electricity bills almost entirely, providing decades of free, clean energy after the system pays for itself.

Environmental Impact

Solar panels can have positive and negative impacts on the environment. On the positive side, solar energy does not emit greenhouse gases or toxic pollutants. Generating electricity from sunlight rather than fossil fuels helps reduce air and water pollution, as well as associated health effects. According to the EPA, one 5 kW solar array eliminates over 4 tons of carbon dioxide emissions per year, equivalent to the annual emissions from driving an average car.

However, there are some environmental concerns with solar panel manufacturing and disposal. Producing the silicon, transistors, and other components requires energy and raw materials. There is debate around whether solar panels create more carbon emissions in their production than they offset over their lifespan. Proper recycling is important, as panels contain lead, cadmium, and other toxic metals. Most panels are estimated to last around 20-30 years. Old solar panels taken out of commission must be handled as electronic waste. Research is underway on how to recycle and reclaim as much material as possible from expired panels.

Overall, most life cycle analyses find solar power has far lower lifetime emissions than fossil fuels. But solar companies are working to further minimize their carbon footprint and environmental impact as much as possible. With responsible manufacturing and recycling practices, solar power can be truly clean and sustainable energy.