How Can We Calculate The Power In The Wind?

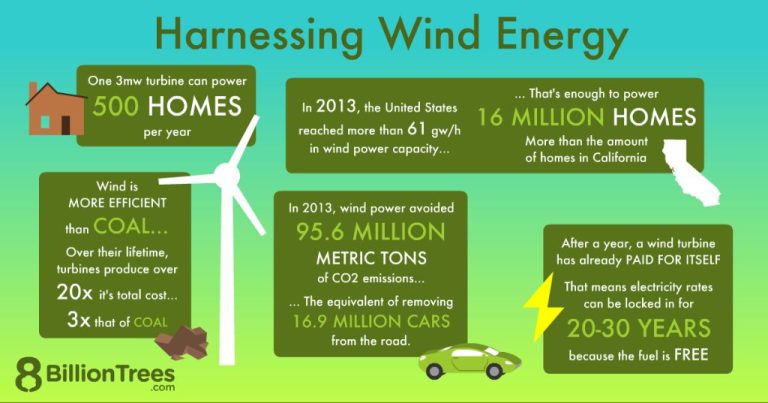

Wind power is energy generated from wind turbines that convert the kinetic energy in wind into mechanical power, which is then converted into electricity. Calculating the amount of power available in wind is important for several reasons:

– It helps determine the feasibility and potential output of a wind energy project for a location. The wind speed and patterns at a site directly impact how much electricity a turbine can generate.

– It allows proper turbine sizing to match the available wind resource. Turbines need to be matched to the wind speeds expected.

– It informs estimates of the revenue and returns possible from a wind project.

– It enables accurate projections of the capacity factor, or how much energy will actually be produced versus the theoretical maximum.

By calculating the extractable power in the wind, we can evaluate locations for wind farms, select appropriate turbines, and estimate the productivity of wind energy projects.

Wind Speed

Wind speed is one of the most important factors in determining the amount of power that can be harnessed from the wind. As a general rule, the power available in wind is proportional to the cube of the wind speed. This means that if the wind speed doubles, the available power increases by a factor of 8 (2^3 = 8).

The reason wind power increases so dramatically with wind speed has to do with the kinetic energy contained in wind. The kinetic energy of a moving object is proportional to the square of its velocity. Since power is the rate of change of energy over time, and the energy in wind goes up with the square of wind speed, the power must go up with the cube of wind speed.

Therefore, sites with higher average wind speeds will allow wind turbines to generate significantly more power. This is why locations with consistent wind resources are ideal for wind farms. For example, according to Windpower (https://energyeducation.ca/encyclopedia/Wind_power), doubling the wind speed from 12 mph to 24 mph increases the available power by a factor of 8.

Faster wind speeds allow the turbine blades to rotate more quickly. Higher rotation speeds result in more mechanical power being captured from the wind. As such, wind turbines are designed to optimize power capture from the range of wind speeds expected at their installation site.

Swept Area

The swept area of a wind turbine refers to the circular area that the turbine blades cover as they rotate. This is an important parameter for calculating the power output of a wind turbine.

For a horizontal axis wind turbine, the swept area is calculated as:

Swept Area = π * R2

Where R is the radius or length of the turbine blade. The larger the swept area, the more wind that can be captured and converted into rotational energy by the turbine. Modern utility-scale wind turbines can have diameters over 100 meters, giving them very large swept areas. The blades are made longer in order to increase energy capture.

According to a theoretical study, adjusting the swept area of a turbine can increase power output. Turbines with variable swept area aim to optimize energy capture in different wind conditions.

Air Density

Air density is an important factor that affects the amount of power that can be generated from wind. Denser air allows wind turbine blades to extract more energy as they spin. Air density depends on several variables including temperature, altitude, and humidity.

Cooler air is denser than warmer air. At higher altitudes, the air is less dense due to lower atmospheric pressure. Humid air is less dense than dry air because water vapor molecules are lighter than molecules of nitrogen and oxygen that make up most of the air. According to a study, a 1°C increase in temperature can decrease air density by about 0.4% and wind power potential by 0.45% (https://ieeexplore.ieee.org/iel5/4907389/4915129/04915156.pdf).

Since less dense air has fewer air molecules for the turbine blades to interact with, the amount of energy extracted from the wind is reduced. Air density needs to be considered, especially when estimating wind power potential across different locations and weather conditions.

Power Coefficient

The power coefficient (Cp) is a dimensionless number that measures how efficiently a wind turbine converts the kinetic energy of the wind into mechanical energy. It represents the fraction of the upstream wind power that is extracted by the turbine. The theoretical maximum Cp is 0.593, known as the Betz limit. But in real-world wind turbines, the Cp value ranges from 0.25 to 0.45.

The power coefficient is calculated using the formula:

Cp = P/(0.5 * ρ * A * v3)

Where P is power output of the turbine, ρ is air density, A is the swept area of the rotor, and v is wind velocity. The power coefficient takes into account the aerodynamic design and operating conditions of the turbine.

Engineers aim to maximize Cp when designing turbine rotors and blades. The optimal tip speed ratio, blade pitch angle, and other factors are selected to get as close to the Betz limit as possible. Understanding the power coefficient curve helps optimize wind farm design and turbine control systems to capture the most energy from the wind.

As cited from this research, the power coefficient reaches a maximum when the pitch angle is around 0 degrees. Increasing the pitch angle causes the power coefficient and overall power output to decrease. The power coefficient is thus a key parameter for modeling turbine performance.

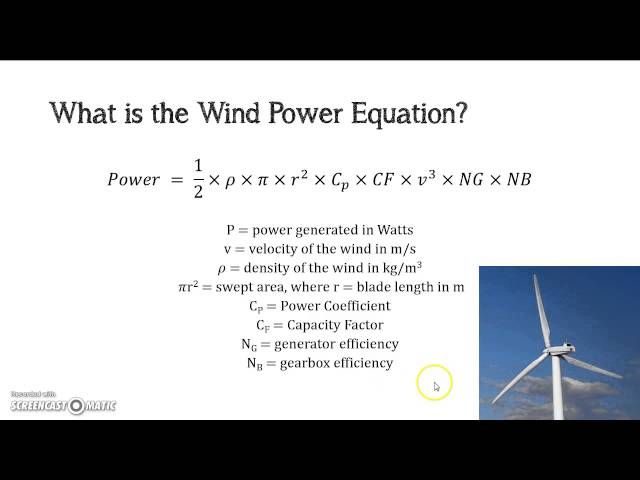

Basic Power Equation

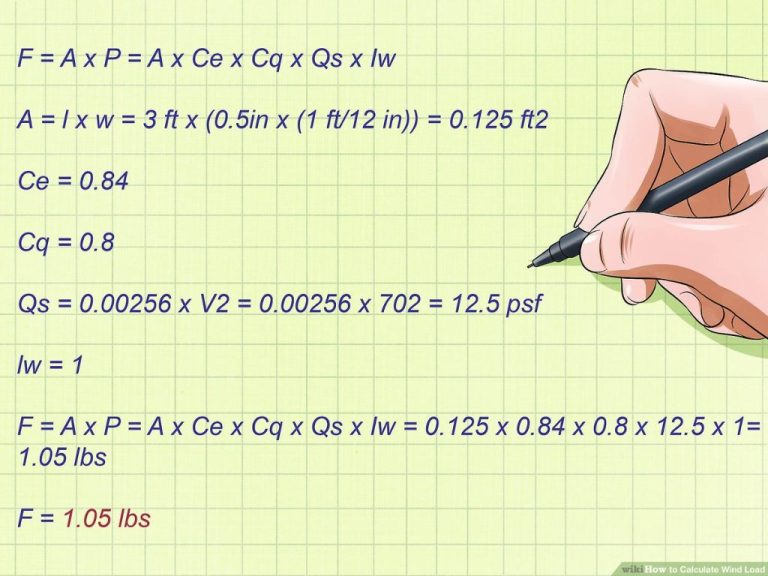

The basic wind power equation calculates the power in the wind based on the following factors:

Power (P) = 0.5 x Air Density (ρ) x Swept Area (A) x Wind Speed (V)3 x Power Coefficient (Cp)

As stated in the IEEE paper referenced on Twinkletoes Engineering, this is the fundamental equation for calculating wind power. The PowerWeb course referenced in the Wind Generation Technology Short Course brochure also indicates this as the standard wind power formula.

To break this down:

- 0.5 is a constant.

- Air density accounts for the mass of air per unit volume.

- Swept area is the area “swept” by the turbine blades.

- Wind speed is the speed of the wind passing through the swept area.

- Power coefficient accounts for efficiency losses in the system.

By inputting values for each of these components, we can calculate the theoretical power available in the wind stream. The next sections will look at each factor in more detail.

Estimating Wind Speed

There are a few key ways to estimate wind speed at a potential wind energy site:

Wind speed data from the nearest meteorological station can serve as a starting point. However, this may not fully represent the wind conditions at the exact site location due to differences in topography and surface roughness. Adjustment factors based on the terrain can help account for these localized effects (Endlich, 1982).

Numerical weather prediction models can also estimate wind speeds by modeling the dynamics of the atmosphere. High resolution models are needed to capture the influence of complex terrain and land cover on wind flow. This approach requires advanced computing capabilities (Mortezazadeh, 2022).

On-site measurements using meteorological towers equipped with anemometers provide the most accurate wind speed data. Monitoring wind speeds at various heights helps characterize the wind profile at the site. However, installing meteorological towers is costly. Short-term measurement campaigns can be used to supplement and validate other estimation techniques (Endlich, 1982).

Overall, a combination of approaches is recommended to provide confidence in wind resource assessments for proposed wind farm locations.

Measuring Swept Area

The swept area of a wind turbine refers to the area of the circle swept by the rotor blades as they rotate. This is an important factor in calculating the power output of a wind turbine.

To measure the swept area, you first need to know the radius of the circle swept by the blades. This is simply the length from the center of rotation (hub) to the tip of a blade. For a typical three-blade horizontal axis wind turbine, the radius R is half of the rotor diameter D.

R = D/2

Once you have the radius measurement, you can calculate the swept area using the formula for the area of a circle:

Swept Area = π x R2

Where π is the mathematical constant, approximately 3.14159. R is the radius of the rotor measured in meters.

For example, if the rotor diameter on a wind turbine is 10 meters, the radius R is 5 meters. Using the formula:

Swept Area = π x 52

= 3.14159 x 25

= 78.5 square meters

Measuring the rotor diameter and using this calculation will give you the swept area value to use in the overall power output estimation.[1]

Accounting for Air Density

The density of air decreases with increasing altitude above sea level. Since wind power is proportional to air density, accounting for changes in air density can significantly improve calculations of wind power production (The Missing Link Between Air Density And Wind Power Production).

Air density can be estimated based on the ideal gas law and the temperature, pressure, and humidity at a given altitude. The standard air density used for wind power calculations is 1.225 kg/m^3 at sea level, 15°C, and 1 atm pressure. The actual density at a wind farm site will likely differ based on the elevation and weather conditions. Adjusting for these differences improves the accuracy of power production estimates.

One method is to calculate the ratio of the actual air density to the standard density. This density ratio can then be used to scale the expected power output. For example, if the air density at a mountain-top wind farm is 0.948 kg/m^3, the density ratio is 0.948/1.225 = 0.774. The estimated power output at the site would be multiplied by this ratio for a more accurate projection (Modelling of the Variation of Air Density).

By accounting for changes in air density due to altitude and weather conditions, wind farm operators can better predict and maximize power production at their specific sites.

Finding Power Coefficient

The power coefficient (Cp) is a parameter that measures how efficiently a wind turbine converts the kinetic energy of the wind into electrical power. The power coefficient ranges from 0 to a theoretical maximum of 0.59 (the Betz limit), with real-world values ranging from around 0.35 to 0.45 for modern commercial turbines.

To determine the power coefficient for a given wind turbine model, you’ll need to consult the manufacturer’s specifications. Most wind turbine manufacturers provide a power curve, which shows the power output across a range of wind speeds. This power curve reflects the real-world power coefficient achieved by that particular turbine design.

Alternatively, the manufacturer may provide the specific power coefficient value for maximum power production. This is the Cp value that should be used when calculating the estimated power output for that wind turbine.

So in summary, the power coefficient can’t be derived through a generic formula. It’s a parameter unique to each wind turbine design, and must be sourced from the manufacturer’s specifications.