How Can Biomass Be Converted Into Biofuels?

Biomass is organic material that comes from plants and animals, and it is a renewable source of energy. Sources of biomass include wood, crops, algae, and organic waste from municipalities, households, and industries. Biofuels are fuels that are derived from biomass. The most common biofuels are ethanol and biodiesel.

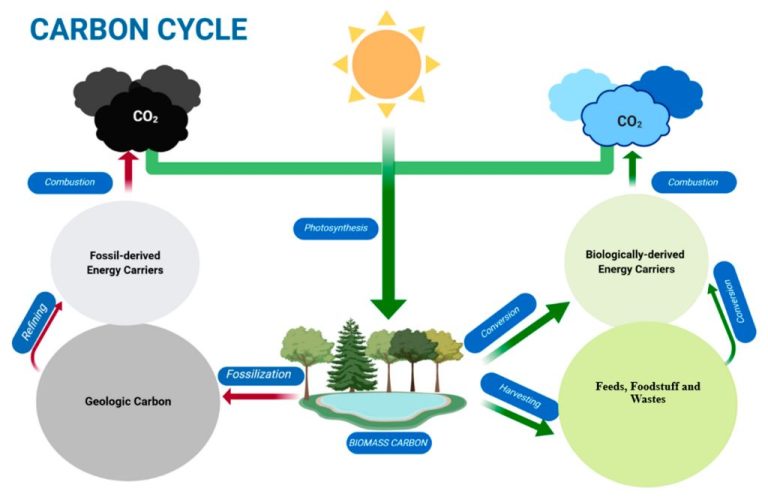

Converting biomass into biofuels is important for several reasons. First, it provides a renewable alternative to fossil fuels which are non-renewable. Fossil fuels like coal, oil and natural gas are being depleted much faster than they are being replenished. Biofuels can provide a sustainable energy source to supplement and replace fossil fuels. Second, biofuels often have lower emissions of greenhouse gases like carbon dioxide compared to fossil fuels. This makes them an attractive option for reducing the carbon footprint of the transportation sector. Finally, producing biofuels domestically can reduce a country’s dependence on imported petroleum. This improves energy security and supports local economies.

Types of Raw Biomass

The main types of biomass used for biofuel production include crops, crop residues, wood, and municipal solid waste.[1] Crops like corn, sugarcane, and soybeans can be processed into ethanol and biodiesel. Crop residues like corn stover, wheat straw, and sugarcane bagasse contain cellulose and hemicellulose that can be converted into cellulosic ethanol. Wood sources such as forest residues, sawdust, and pulp waste contain lignocellulose that can also be converted into biofuels. Municipal solid waste containing paper, cardboard, food scraps, grass clippings, and sewage sludge can produce biomethane through anaerobic digestion.

Pretreatment Methods

Pretreatment is an important step in converting biomass into biofuels. It helps break down the rigid structure of lignocellulosic biomass to make the cellulose and hemicellulose more accessible for downstream processing into biofuels. Pretreatment methods can be classified into physical, chemical, physico-chemical and biological methods.

Mechanical pretreatment methods like chipping, grinding and milling help reduce the particle size and crystallinity of biomass. This increases the surface area for greater enzymatic digestion. Thermal pretreatment like steam explosion helps solubilize hemicellulose and lignin. Chemical pretreatment uses acids, alkalis, oxidizing agents or solvents to remove lignin and hemicellulose. Common chemical pretreatments include dilute acid, alkaline, and organosolv pretreatments. Physico-chemical pretreatments like Ammonia Fiber Expansion (AFEX) combine physical and chemical pretreatment for improved efficiency. Biological pretreatment uses microorganisms like brown, white and soft-rot fungi to degrade lignin and hemicellulose (https://www.sciencedirect.com/science/article/pii/S2352186422002139).

Selecting optimal pretreatment methods depends on the biomass type, desired products, environmental factors, capital and operating costs. Multi-step or hybrid pretreatments combining physical, chemical and biological methods are gaining popularity for improved biofuel yields.

Biochemical Conversion

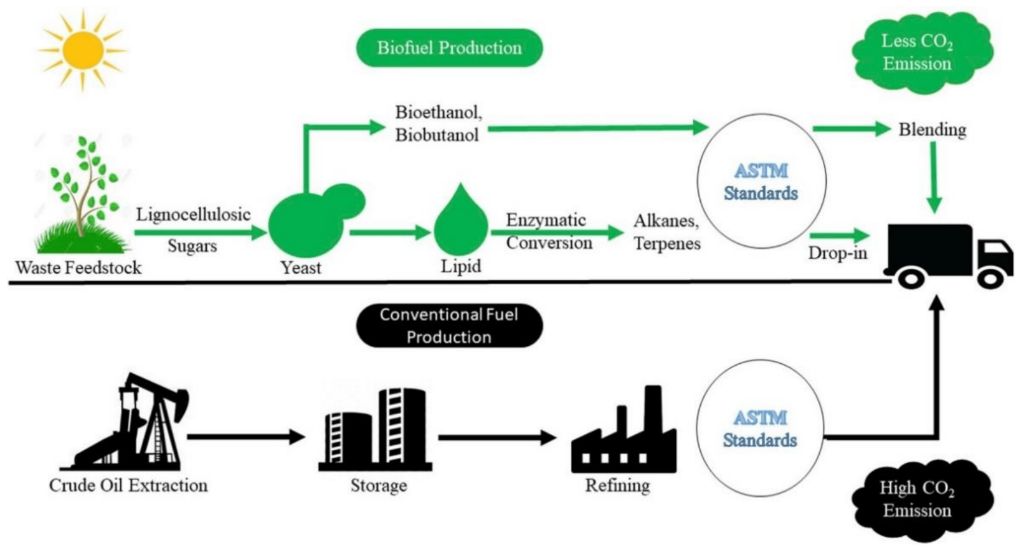

Biochemical conversion involves using enzymes, microorganisms, or both to convert biomass into biofuels. This process utilizes the sugars in biomass and converts them into biofuels through biological processes like fermentation. The most common biochemical conversion method is fermentation, where sugars like glucose are converted into ethanol by microorganisms like yeast or bacteria in anaerobic conditions.

Cellulose and hemicellulose, which make up a large portion of biomass, need to be broken down into simple sugars before they can be fermented into ethanol. This is done through hydrolysis using acids, enzymes like cellulase, or a combination of both. The simple sugars produced are then fed to microorganisms in fermentation tanks. The microbes metabolize the sugars and produce ethanol as a byproduct.

Fermentation is commonly used to produce fuel ethanol from crops like corn and sugarcane. But it can also produce ethanol from cellulosic biomass like wood chips, agricultural residues, and grasses. The advantage of biochemical conversion is that it relies on simple, natural biological processes to produce biofuels. However, the pretreatment and hydrolysis steps make it more complex compared to other conversion methods. Research is focused on making the process more efficient through advanced enzyme cocktails and engineered microorganisms.

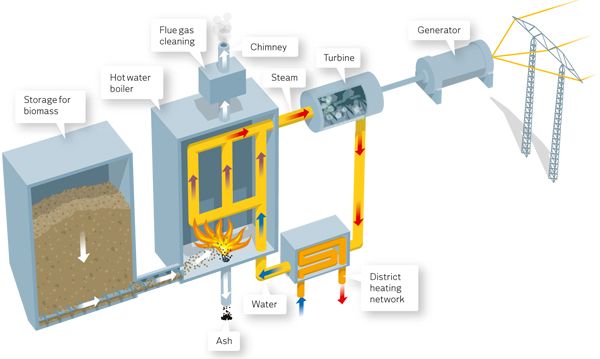

Thermochemical Conversion

Thermochemical conversion involves the use of heat to breakdown biomass into liquids, gases and biochar. The main thermochemical conversion methods for producing biofuels from biomass include pyrolysis, gasification, and liquefaction.

Pyrolysis involves heating biomass in the absence of oxygen to temperatures around 500°C. This breaks down the biomass into bio-oil, syngas, and biochar. Fast pyrolysis optimizes bio-oil production, while slow pyrolysis maximizes biochar yield [1].

Gasification converts biomass into syngas (CO + H2) by heating to high temperatures (700-1000°C) with a controlled amount of oxygen. The syngas can then be converted into various fuels via Fischer–Tropsch synthesis [2].

Liquefaction uses catalysts to convert wet biomass like microalgae into biocrude at high pressures (5-20 MPa) and temperatures (250-400°C). The biocrude can then be refined into liquid transportation fuels [3].

Catalytic Conversion

Catalytic conversion is an important process for converting biomass into liquid transportation fuels like biodiesel and green diesel. This involves using catalysts to break down and convert the oils, fats, and other compounds in raw biomass feedstocks.

One common approach is transesterification, which uses catalysts like sodium hydroxide or potassium hydroxide to convert triglycerides in oils and fats into fatty acid methyl esters (FAMEs) – the chemical name for biodiesel. The triglycerides react with methanol in the presence of the basic catalyst to produce glycerol and biodiesel (FAMEs) (Yoo, 2020).

Another pathway is hydrotreating, also called hydroprocessing, which uses catalysts like cobalt, molybdenum, and nickel together with high pressure hydrogen gas to remove oxygen and convert oils into hydrocarbon diesel-range molecules known as green diesel. Hydrotreating is effective for producing high quality diesel fuels from a variety of biomass oils including vegetable oils, waste cooking oils, and algal oils (Akram, 2023).

Catalytic conversion methods offer a number of benefits compared to biochemical conversion. Catalysts allow the reactions to take place at much lower temperatures, lower pressures, and faster rates. The hydrocarbon biofuels produced are chemically identical to petroleum-based fuels, and can be mixed and distributed using existing infrastructure. Catalytic conversion expands the feedstock options beyond sugars and starches to include oils and fats (Kim et al., 2020).

Biofuel Products

The main biofuel products from biomass conversion include:

- Ethanol – A liquid alcohol fuel produced from fermenting the sugars in biomass. It can be blended with gasoline for use in vehicles.

- Biodiesel – A diesel fuel substitute produced from oils or fats using transesterification. It can replace petroleum diesel in engines.

- Biogas – A gaseous mixture of methane, carbon dioxide and other gases produced from anaerobic digestion of organic matter. It can be used for heating, electricity generation and as a vehicle fuel.

- Syngas – A gas mixture of carbon monoxide, hydrogen and carbon dioxide produced from gasification of biomass. It can be further processed into synthetic fuels.

- Bio-oil – A viscous liquid produced from fast pyrolysis of biomass. It requires further upgrading to become a transport fuel.

- Hydrogen – A clean fuel produced from biomass via thermochemical or biological processes. It has potential for use in fuel cells.

These biofuels offer renewable alternatives to fossil fuels, with some products being near direct replacements, while others require engine or infrastructure modifications for utilization.

Environmental Benefits

Biofuels provide several key environmental benefits compared to fossil fuels like gasoline and diesel. According to the U.S. Department of Energy, using biofuels can significantly reduce greenhouse gas emissions as they absorb CO2 while growing, which offsets the CO2 released when they are burned as fuel (https://www.energy.gov/eere/bioenergy/environmental-benefits). Specifically, corn ethanol reduces greenhouse gas emissions by 20-30% on average compared to gasoline. Biodiesel from soybean oil can reduce emissions by 57-86% compared to diesel fuel.

In addition to reducing greenhouse gases, biofuels burn cleaner than fossil fuels and can reduce emissions of particulate matter, carbon monoxide, and sulfur oxides, leading to improved air quality (https://auto.howstuffworks.com/fuel-efficiency/biofuels/environmental-benefits-biofuel.htm). Biofuels are also biodegradable and non-toxic, minimizing the potential for environmental contamination from spills. Since biofuels are made from renewable plant sources that can be replanted rather than finite fossil fuel reserves, they provide a more sustainable long-term energy solution.

Widespread use of biofuels could support energy independence by relying on domestic agricultural sources rather than imported oil. However, large-scale biofuel production raises concerns about land and water use. Balancing these tradeoffs is an active area of research to maximize the environmental benefits of biofuels.

Economic Considerations

Biofuel production from biomass can have several economic benefits and tradeoffs that need to be analyzed to determine the feasibility of various conversion processes. Some of the key economic considerations include the following:

- Feedstock costs: The cost of acquiring and transporting sufficient raw biomass is a major determinant of overall biofuel production costs. Waste biomass streams like agricultural or forestry residues tend to be cheaper than purpose-grown energy crops.

- Capital costs: Building new biofuel production facilities requires major upfront investments. Thermochemical processes often have higher capital costs for construction compared to biochemical conversion.

- Operating costs: Expenses for labor, utilities, maintenance etc. add to the ongoing costs of biofuel production. Continuous processing can lower costs compared to batch methods.

- Government incentives: Tax credits, loan guarantees and other policies that promote biofuels can improve profit margins. However policies are variable and uncertain.

- Oil prices: Since biofuels compete with fossil fuel products, lower oil and gasoline prices reduce biofuel competitiveness.

- Co-products: Valuable chemicals, fertilizers, animal feeds etc. derived during processing can provide additional revenue streams.

- Life cycle assessments: Cradle-to-grave environmental impacts should be evaluated to account for sustainability benefits.

Detailed techno-economic analyses and life cycle assessments are required to determine if a particular biomass feedstock, conversion pathway and project scale will be economically viable. Government incentives can help offset initial capital costs and ongoing production expenses. Overall, continued technological improvements that increase conversion efficiency and reduce costs are critical to make biofuels economically competitive with fossil fuels.

Conclusion

Biomass conversion into biofuels is a promising alternative energy solution with many benefits. As highlighted in this article, biomass sources like plants, crops, and waste can be pretreated and then processed through biochemical, thermochemical, or catalytic conversion methods to produce useful biofuels like ethanol, biodiesel, biogas, and more. Key points covered include the types of raw biomass available, different conversion processes, resulting biofuel products, environmental advantages like reduced fossil fuel dependence and greenhouse gas emissions, and economic considerations around scaling production. Converting biomass into biofuels has the potential to provide renewable, sustainable energy to meet growing global demand. Though some challenges remain, continued research and investment into efficient technologies can further develop biomass as a viable source for fuels, energy, and other bioproducts.