Do Windmills Have To Have Lights?

Wind power has become an increasingly important source of renewable energy worldwide. According to the International Energy Agency, the share of wind power in Europe’s energy mix grew from 14% in 2019 to 15% in 2020 (Source). With many countries setting ambitious renewable energy targets, the expansion of wind power is set to continue. However, for many the sight of windmills dotting the landscape still provokes questions. Do windmills need to have lights on them? Why are some lit while others are not? In this article, we’ll take a closer look at windmill lighting: the regulations, purpose, options, and why proper lighting is crucial for these soaring giants.

Purpose of Windmill Lighting

The primary purpose of windmill lighting is for aviation safety. Wind turbines can reach heights of over 400 feet, extending into airspace used by low-flying aircraft. To increase visibility and prevent collisions, the FAA requires certain lighting standards based on the turbine’s height and location (FAA Wind Turbine FAQs, 2023). Red flashing lights are commonly used to mark obstructions and warn pilots of potential hazards. Standards help create consistency so pilots know what to expect when approaching wind farms. Lighting allows wind turbines to coexist safely with aviation activities, protecting people in the air and on the ground.

Types of Windmill Lighting

Wind turbines require lighting at night for aviation safety. The most common lighting types are red flashing lights and white strobe lights. According to the FAA, all wind turbines over 200 feet tall need lighting systems to make them visible to aircraft (https://www.faa.gov/newsroom/faa-issues-faqs-about-tower-lighting-marking).

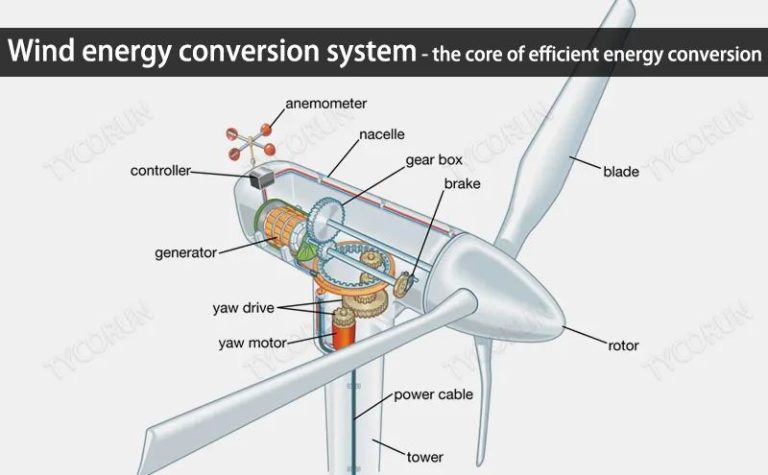

Red flashing lights are the most common lighting used on wind turbines at night. These lights flash around 30 times per minute to highlight the structure. They are typically placed at the top of the nacelle so the flashing is visible from all directions (https://kythira-windturbines.com/en/wind-turbines-remain-visible-all-night/).

White strobe lights provide daytime visibility. These bright Xenon lights pulse at the same rate as the red flashing lights for consistency. White strobes provide increased visibility during daylight hours, dusk, and dawn when the red lights may be difficult to spot.

Lighting Requirements by Height

The FAA has specific lighting requirements for wind turbines based on the structure’s height. According to the FAA’s Advisory Circular 70/7460-1L [1], wind turbines 500 feet or taller above ground level (AGL) must have flashing red obstruction lights installed on the nacelle. Lights must flash simultaneously and have a minimum intensity of 200,000 candelas during the day and 20,000 candelas at twilight.

For wind turbines between 200-499 feet AGL, at least one red flashing obstruction light must be installed on the highest point of the nacelle. The minimum intensity for this light is 32 candelas day and night. Structures under 200 feet AGL generally do not require obstruction lighting, provided there are no unlit gaps over 1/2 mile. [2]

Wind farms with multiple turbines must have synchronized flashing lights, per FAA standards. Obstruction lighting helps increase visibility and safety for nearby aircraft. Proper lighting is crucial, as wind turbines can be difficult to see and avoid without adequate illumination.

[1] https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_70_7460-1L_.pdf

[2] https://cleanpower.org/wp-content/uploads/2021/01/FinalVersion_Wind-Turbine-Lighting-Fact-Sheet-3.23.22.pdf

Lighting Options and Costs

A modern windmill will typically have several lighting options to meet safety and visibility requirements. The most common options include:

Aviation Warning Lights

This is typically a flashing red beacon placed on the top of the nacelle to warn approaching aircraft. Depending on the model, the costs range from around $300 for an entry-level beacon to over $2,000 for a high-quality LED beacon designed to maximize visibility and durability.

Nacelle Interior Lights

These are interior lights within the nacelle housing to illuminate the machinery for maintenance and repairs. Interior lighting costs between $100 to $400 depending on brightness and energy efficiency.

Tower Lights

Light fixtures mounted at intervals on the exterior of the tower to improve visibility for aviation and ground navigation. Individual fixtures cost between $150-$750. A 300 foot tower may require 8-10 fixtures for full lighting coverage at a total materials cost of $2,000 or more.

Obstruction Lighting Control

A control system to operate the aviation lighting based on environmental conditions. Costs range from $150 for a simple timer switch to over $1,500 for a smart control system that adjusts output based on visibility and proximity sensors.

Lighting Challenges

Wind turbines can face several lighting challenges that impact maintenance and operations. One key issue is failed or faulty lighting fixtures. As noted by Phoenix Lighting, “Failed lighting fixtures may put turbines out of commission or prevent routine maintenance procedures, which can pose health and safety risks” (https://www.phoenixlighting.com/resources/blog/3-lighting-challenges-offshore-wind-turbines-and-how-to-solve-them). Replacing bulbs and fixtures on wind turbines is difficult and expensive due to the heights involved.

Bird collisions are another key concern related to wind turbine lighting. The Clean Power Alliance notes that “Nighttime obstruction lighting should consist of FAA L-864 aviation red flashing strobe lights to minimize bird attraction and collisions” (https://cleanpower.org/wp-content/uploads/2021/01/FinalVersion_Wind-Turbine-Lighting-Fact-Sheet-3.23.22.pdf). Red strobe lighting is preferable to solid red or white lighting to help reduce impacts on migrating birds and other wildlife.

Lighting Innovations

New technologies have arisen in recent years to mitigate the lighting concerns posed by wind turbines. One such innovation is radar-activated lighting systems, known as Aircraft Detection Lighting Systems (ADLS). As described by KLRD, ADLS uses radar technology to activate the flashing red lights on wind turbines only when low-flying aircraft are detected in the vicinity. This allows the lights to be turned off the majority of the time. According to MidAmerican Energy, ADLS is expected to eliminate the flashing red lights on turbines by over 95%.

Another recent advance is the use of LED lighting. As explained by Flash Technology, LED obstruction lights for wind turbines are extremely energy efficient and have lifespans of up to 100,000 hours. LED lights also allow for options like dimming and slow pulsing to further reduce community impacts. The long lifespan of LEDs also reduces maintenance costs and turbine downtime.

Community Concerns

One of the primary concerns around wind turbine lighting from local communities is light pollution. The red flashing lights on wind turbines can be visible for miles, especially at night. This can negatively impact views of the night sky and disrupt sleep for some residents living near wind farms (Aaen et al., 2022). There are also aesthetic concerns, as some find the lights visually unappealing and feel they detract from rural or natural landscapes (CNN, 2023).

Residents have raised complaints about wind turbine lighting impacting quality of life. However, regulations require certain lighting for aviation safety, so communities don’t always have a choice. This has fueled opposition to some wind energy projects. Strategies like using radar-activated lighting at night may help address some complaints while maintaining safety.

Benefits of Windmill Lighting

One of the main benefits of windmill lighting is improved aviation safety. The Federal Aviation Administration (FAA) requires wind turbines over 200 feet tall to have synchronized red lights on top to make them visible to low-flying aircraft (see source 1). This helps pilots see and avoid wind turbines at night or in low visibility conditions, preventing hazardous collisions. The red synchronized flashing beacons on wind turbines have a luminous intensity of at least 32 candelas to make them clearly visible from the air. While some local residents find wind turbine lights visually unappealing, they provide an essential aviation safety function.

In addition to assisting pilots, wind turbine lighting systems also increase safety for maintenance workers who need to access turbines at night for repairs or upkeep. The lights illuminate the area so technicians can see what they are doing. Wind turbine lighting is a practical necessity for improving visibility and operational safety.

Conclusion

In conclusion, wind turbine lighting is an important safety feature for both air traffic and local communities. While lighting can be an annoyance and eyesore for some, regulations require taller wind turbines to have navigation lights for aviation safety. The color, brightness, and flashing patterns of wind turbine lights are optimized to increase visibility while minimizing disturbance. New innovations like aircraft detection lighting and LEDs can further reduce impacts. Though a minor drawback, lighting is essential for allowing wind power expansion and the benefits it provides. Wind turbines are a clean energy technology, and reasonable compromises like safety lighting are needed for them to be implemented on a large scale.