Do Wind Turbines Require Rare Earth Metals?

Wind turbines are renewable energy devices that convert the wind’s kinetic energy into electrical power. They have become an increasingly important source of clean, renewable energy around the world. Rare earth metals refer to a group of 17 elements that have unique magnetic, optical, and catalytic properties. These metals play a critical role in technologies like wind turbines, electric vehicles, and consumer electronics.

There has been some debate around whether wind turbines require rare earth metals to function. This is an important issue because rare earth metals mining carries environmental risks, and global supply chains for these materials can be precarious. Understanding the role of rare earths in wind power will shed light on the sustainability and future growth potential of this key renewable energy technology.

What Are Rare Earth Metals?

Rare earth metals, sometimes referred to as rare earth elements or rare earth oxides, are a set of 17 chemical elements on the periodic table. They include scandium, yttrium, and the 15 lanthanide elements such as cerium, praseodymium, and neodymium. Despite their name, rare earth metals are not necessarily rare in quantity – some are about as abundant in the earth’s crust as copper, lead, gold, or platinum. However, they tend to be dispersed in low concentrations rather than concentrated in economically exploitable deposits.

What makes rare earth metals unique is their distinctive magnetic, catalytic, and electrochemical properties. This is due to their partially filled 4f and 5d electron shells, which enable them to form versatile compounds and alloys. They have become essential across a wide range of advanced technologies and “green” products such as smartphones, computer memory chips, rechargeable batteries, LEDs, electric and hybrid vehicles, and precision-guided weapons systems. Within renewable energy, rare earth metals are vital for wind turbines, energy-efficient lighting, and solar panels.

Some of the most important rare earth metals include neodymium and dysprosium used in permanent magnets, and terbium used in fluorescent lamps. Due to their specialized uses, substitution or recycling is difficult and limits exist on sourcing rare earth metals. China currently produces over 80% of the global supply of rare earth metals, creating a strategic vulnerability for countries dependent on rare earth imports.

Uses of Rare Earth Metals

Rare earth metals are crucial ingredients in many modern technologies today, especially electronics and renewable energy. Some of the major uses include:

Magnets – Rare earth permanent magnets made from neodymium, samarium, and dysprosium are extremely strong and lightweight. They are used in computer hard drives, headphones, electric vehicles, wind turbines, etc. These enable miniaturization and efficiency in tech devices. https://idealmagnetsolutions.com/knowledge-base/rare-earth-metals-12-things-about-neodymium/

Batteries – Lanthanum, cerium, neodymium, and praseodymium help improve battery performance in electronics and electric vehicles. They enable longer life, faster charging, and high power output.

Displays – Europium and yttrium are used in LEDs and display screens to create red and green phosphors. This gives bright, energy efficient illumination in devices.

Catalysts – Cerium and lanthanum are added to catalytic converters and refineries. They help speed up chemical reactions and remove impurities.

Alloys – Scandium, yttrium, and lanthanum can strengthen or lighten aluminum alloys used in aircraft, cars, and bicycles.

The unique magnetic, phosphorescent, catalytic, and metallurgical properties of rare earths have become essential to much of the technology we use daily. Their supply limitations make recycling and alternatives important for the future.

Importance in Wind Turbines

Rare earth metals, especially neodymium and praseodymium, are critical components in the permanent magnets used in wind turbine generators. According to Wind Power Monthly, “The main rare-earth metals used in wind turbines are neodymium and praseodymium. They are used in direct-drive permanent magnets in generators.” https://www.windpowermonthly.com/article/1037723/us-fears-chinese-stronghold-rare-metals-will-tighten

A study from Diva Portal notes, “In fact, the criticality of neodymium along with other rare earth metals used in wind turbines manufacture is less mentioned in current research studies.” Direct drive wind turbines can contain up to 600 kilograms of rare earth magnets. https://www.diva-portal.org/smash/get/diva2:668091/FULLTEXT01.pdf

Rare earth metals help create strong, lightweight magnets that improve generator efficiency. Without these metals, wind turbine performance would decrease significantly.

Other Components

While rare earth metals can play an important role in some wind turbines, there are many other major components that make up these complex machines. According to STEM PROJECT1, the key components of a wind turbine include:

- The rotor blades which capture the wind energy.

- The hub which connects the blades to the main shaft.

- The main shaft which connects to the gearbox and generator.

- The gearbox which converts the rotational speed.

- The generator which converts the mechanical energy into electrical energy.

- The tower which elevates the turbine to reach stronger winds.

According to GetMaintainX2, other major components are:

- The nacelle which contains the gearbox, generator, and other machinery.

- The yaw system which orients the turbine into the wind.

- The controller which monitors and optimizes performance.

- The transformer which steps up the voltage for transmission.

While magnets containing rare earth metals can be found in some wind turbine generators, there are many complex and critical components made of more common materials like steel, fiberglass, copper, and aluminum.

Alternatives

There is ongoing research into alternatives to rare earth metals for use in wind turbines due to concerns around supply constraints and environmental impacts of mining rare earths. According to scientists at Ames Laboratory, two promising candidates have been identified that could reduce reliance on rare earth metals: cerium cobalt alloys CeCo3 and CeCo5. Cerium is already classed as one of the more abundant rare earth metals, so alloys using it could provide a more sustainable alternative (Source).

Other research has focused on using ferrite magnets as a substitute, which require more abundant elements like iron and zinc. While not as powerful currently, improvements in material processing and new compositions could make ferrite competitive. Recycling magnets from old turbines is another important strategy to recover rare earths and reduce the need for new mining (Source).

Overall, reducing reliance on rare earth metals through new material science will be key to scaling up wind power sustainably. Though small amounts are needed per turbine, global demand could strain supply without proper planning and alternatives.

Recycling

Recycling rare earth metals from old wind turbines presents both opportunities and challenges. Currently, recycling rates for rare earth metals are very low, with less than 1% being recovered from end-of-life products and reused.1 However, as more turbines are decommissioned, recycling rare earths could provide a valuable domestic source of these materials.

Recycling wind turbine magnets can be technically challenging. The magnets deteriorate through corrosion and oxidation over the turbine’s lifetime. The composition and properties of the recycled material may not match new rare earth alloys. Processes for separating and extracting the rare earths from other materials are complex and energy intensive.2

Nonetheless, recycling is seen as essential for securing rare earth supply chains. Improvements in separation techniques and processing costs could boost recycling rates. Policies like extended producer responsibility and required recycling targets may also incentivize more recycling. Overall, recycling end-of-life wind turbines provides the opportunity to recover valuable materials and reduce the environmental impacts of new rare earth mining and processing.

Supply Issues

There are concerns around the global supply of rare earth metals, as production is currently dominated by China. China produces over 80% of the global supply of rare earth metals, giving it a near monopoly and raising worries about the availability and pricing of these materials (https://www.wsj.com/articles/the-u-s-wants-a-rare-earths-supply-chain-heres-why-it-wont-come-easily-dfc3b632). This concentration of production in one country poses risks, as global supply could be disrupted by political tensions, trade disputes, or other unforeseen events. For example, China temporarily suspended rare earth exports to Japan in 2010 over a maritime dispute, causing prices to spike worldwide. Countries like the US are pushing to develop their own domestic rare earth supply chains to reduce dependence on imports from China.

There are also concerns around responsible and sustainable mining practices with rare earth metals. As demand rises, there will need to be expanded mining capacity while ensuring operations avoid environmental damage and human rights abuses (https://www.circularise.com/blogs/the-rare-earth-problem-sustainable-sourcing-and-supply-chain-challenges). Tighter regulations and vetting of global rare earth suppliers will be important to make sure expanded production meets ethical and ecological standards.

Outlook

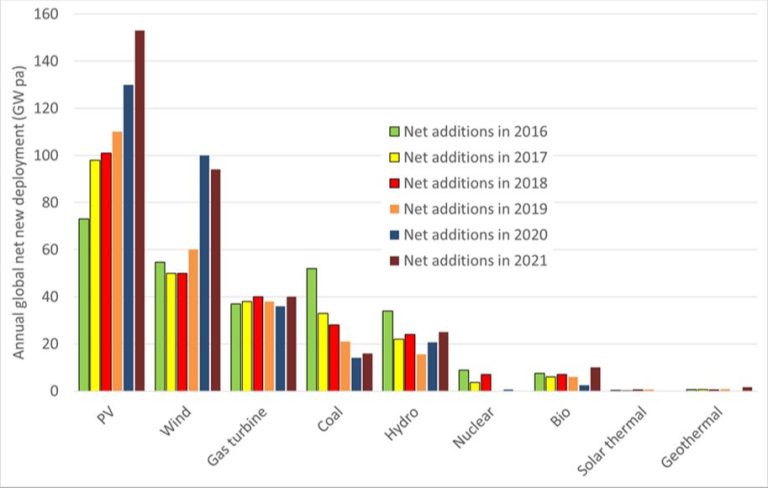

The future demand for rare earth metals in clean energy like wind turbines is expected to grow significantly in the coming years. According to a 2020 report, demand for rare earths in wind turbines could increase by 700-2000% by 2050 depending on the renewable energy deployment scenario. This is driven by the rising number of wind turbines being built globally to meet clean energy goals and the increasing size and efficiency of turbine technology requiring more rare earth metals.

However, the supply outlook for rare earths is uncertain. Currently, China controls over 80% of global rare earth production and processing. This concentration of supply poses risks of shortages and price volatility. Opening new rare earth mines can take 5-10 years due to permitting and environmental regulations. Alternatives and recycling may help meet some demand, but total supply is expected to remain tight given projected clean energy growth. Securing adequate rare earths in a sustainable and ethical manner will be a key challenge for the energy transition.

Conclusion

In summary, wind turbines generally do not require rare earth metals to function. While some models utilize neodymium magnets that contain rare earths like neodymium and dysprosium, many turbines rely on other components like gearboxes and asynchronous generators that do not need rare earths. Some turbine designs are also shifting toward direct drive and permanent magnet generators that reduce the need for gearboxes and magnets containing rare earth metals. While rare earth metals offer performance advantages in terms of power and weight, wind turbines can still operate without them. Manufacturers are actively researching alternatives and ways to recycle rare earths to maintain a supply. So in conclusion, while rare earth metals can improve turbine design, they are not an absolute necessity in modern wind turbines.