Can Solar Panels Be Transported?

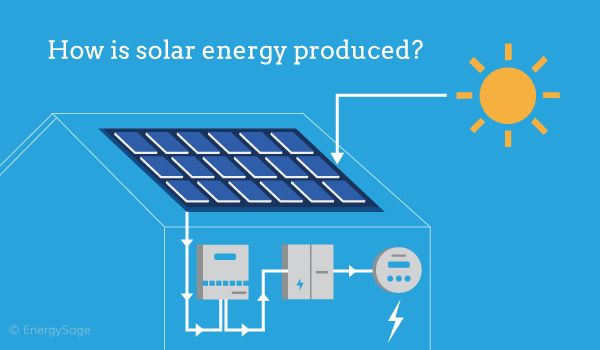

Solar panels are devices that convert sunlight into electricity using the photovoltaic effect. As concerns about climate change and energy security grow, demand for solar panels is rapidly increasing around the world. The solar industry is expanding at a rate of over

20% per year, and over 2.5 million homes in the U.S. now have rooftop solar panels installed 1. With this growth comes the need to transport solar panels safely and efficiently from manufacturers to installation sites.

Transporting solar panels presents some unique logistical challenges due to their large size, fragility, and specialized shipping requirements. This article will examine how solar panels can be transported by truck, ship, and air while avoiding damage.

Why Transport Solar Panels?

There are several key reasons why transporting solar panels is necessary:

Installation – New solar panels need to be transported from the manufacturer to the installation site, whether it’s a residential roof, commercial building, or solar farm. Panels are large, heavy and fragile, so specialized transport is required.

Maintenance and Repairs – Once installed, solar panels occasionally need maintenance, repairs or replacement. Transporting individual panels or sections allows this work to be completed efficiently.

Relocation – Existing solar panel systems are sometimes relocated when a home or business moves. Careful transport minimizes the risk of damage during the move.

Disposal and Recycling – Solar panels have a finite lifecycle and will eventually need disposal. Transporting end-of-life panels to recycling facilities helps recover valuable raw materials for re-use.

In summary, the installation, maintenance, relocation and disposal of solar PV systems all require the safe transportation of solar panels. Specialized logistics help minimize the risk of damage in transit.

For more details, see this helpful overview on protecting solar panels during transit.

Weight and Dimensions

Solar panels come in a wide range of sizes and weights, depending on the output wattage and type of solar panel. Residential solar panels typically range in size from 39 inches x 26 inches up to 77 inches x 39 inches for large commercial panels. The typical weight of a standard 60-cell residential solar panel is around 40-50 pounds (18-23 kg). Some key specs on solar panel weight and dimensions include:

Standard 60-cell residential solar panels are usually around 65 inches x 39 inches and weigh 40-50 pounds each according to Velo Solar. 72-cell residential panels are a bit larger and heavier at around 77 inches x 39 inches and 50-60 pounds each.

Larger commercial solar panels can measure up to 84 inches x 42 inches and weigh up to 110 pounds according to Freedom Solar Power. However, the average weight of a commercial solar panel is about 55 pounds.

Solar shingles and solar tiles are smaller and lighter than traditional panels. According to Bluetti Power, Tesla solar shingles weigh around 4-5 pounds per square foot of coverage.

Fragility

Solar panels are designed to be durable, but they do contain fragile components that require care in handling and transport. The glass covering the solar cells is susceptible to cracking or breaking if subjected to excess pressure or impact. According to Solar Panel Talk, solar panels can generally withstand extreme weather conditions like high winds if properly mounted, but the glass is not indestructible.

The solar cells and wiring inside the panel are also fragile components. As explained by Sun Soaked Solar, walking on solar panels can potentially damage the cells and wiring by causing micro-cracks or disconnects. So precautions need to be taken to avoid excess pressure on the panels during transport and installation.

When transporting solar panels, they should be handled with care and properly secured to avoid shocks, drops, or excess vibration that could crack the glass or damage internal components. Shock-absorbing packaging materials and secure tie-downs are recommended. The panels should also be kept upright and supported throughout transit to prevent bending or warping of the frame. Taking these precautions helps ensure the solar panels arrive safely at their destination fully intact and functional.

Transport Methods

There are several main methods for transporting solar panels, each with their own pros and cons:

Truck Transport

Transporting solar panels by truck is a common method for domestic shipping within the same country. Trucks allow for door-to-door delivery without having to reload the solar panels multiple times. However, trucking can be more expensive for international transport and may not be feasible for overseas shipping.

Trucks should have air ride suspension and tie downs to securely fasten the solar panels during transport and absorb bumps in the road (1).

Shipping Transport

Transporting solar panels by sea in shipping containers is a popular method for international delivery. Shipping is more affordable than air freight for large, heavy solar panel loads going overseas. However, delivery can take weeks to months depending on the destination.

Solar panels must be carefully packed in crates within the shipping container to prevent damage during transit. Shockwatch indicators should be used to monitor any impacts or drops (2).

Air Transport

When speed is critical, air transport via cargo plane is the fastest method for shipping solar panels internationally. Air freight is significantly more expensive than sea freight, but can cut transit time down from months to days.

Solar panels need extra secure packaging and often have weight limitations when shipped by air.

Truck Transport

Trucks are one of the most common ways to transport solar panels, especially for deliveries that are within the same region or country. Trucks allow you to haul multiple solar panels at once and provide protection against road conditions. When using a truck, it’s important to properly secure the solar panels to prevent damage.

Solar panels should be stacked vertically on their sides when transported by truck, with the glass facing inwards towards other panels. Foam spacers or cardboard should separate each panel to prevent them from rubbing together. Panels must be strapped down tightly to the truck bed using ratchet straps or specialty equipment like panel racks. Straps should be placed across the middle of the panel and anchored to the truck bed for maximum hold.

It’s also crucial to drive slowly and avoid potholes or bumps when transporting solar panels by truck. Sudden jolts or impacts can crack the glass or damage the interior components. Most experts recommend keeping speeds under 55 mph. Additionally, the route should be surveyed in advance to find the smoothest roads possible (Source).

The cost of transporting solar panels by truck varies based on distance traveled and amount of panels. For a local delivery, expect to pay around $1 per mile per panel. Long-haul trucking can be $2-4 per mile per panel. Overall, truck transport provides a flexible and low-cost way to safely move solar panels.

Shipping Transport

When shipping longer distances, many solar panel installers and manufacturers utilize container ships for transport. Shipping via sea in containers allows for transporting a high volume of solar panels while keeping costs relatively low compared to other shipping methods. According to FreightCenter, shipping containers can hold between 20 and 40 pallets of solar panels. The panels are carefully stacked and secured within the container using braces and straps to prevent damage during transit.

When preparing solar panels for container transport, it’s important to pack them vertically and face the front sunny side inwards towards other panels. This helps minimize the risk of damage according to Arviem. Padding and foam sheets can be used between panels for extra protection. The container’s vibration and motion during shipping pose the biggest threats to the panels. Proper securing and stacking is key.

The cost to ship solar panels by sea depends on the container size, distance, port fees, and other factors. From China to the US West Coast, estimates range from $2,000-$4,000 for a 40-foot container holding up to 1,000 standard 60-cell panels according to FreightCenter. Despite longer transit times, sea shipping provides a cost-effective option to transport large volumes of solar panels worldwide.

Air Transport

Shipping solar panels by air is often the fastest method for transporting them long distances, but also the most expensive. Air freight is commonly used when delivery times are critical or for shipping to remote locations not easily accessible by road or sea. There are some key considerations for transporting solar panels by air:

Weight restrictions – Cargo planes have weight limits that need to be considered. Large shipments may need to be split up into multiple air shipments. Dimensional weight also needs to be factored in.

Fragility – Extra precautions need to be taken to protect solar panels from damage. Shock absorption, securing panels, and adding protection between panels is important.FreightCenter recommends using air ride suspension trucks for delivery to and from the airport.

Cost – Air freight has much higher costs than other shipping methods. Fuel surcharges, dimensional weight calculations, and airport storage fees can add up quickly. It’s recommended for time-sensitive shipments only.

Customs – Shipping internationally by air requires proper customs paperwork and duties to be paid. A customs broker is advisable to ensure smooth clearance.

Crating – Solar panels need to be properly crated to withstand the vibrations and movements of air travel. Sturdy wooden or metal containers specifically designed for air transport should be used.

Consolidation – For large orders, solar panels from multiple suppliers can be consolidated into one air shipment via a freight forwarder to reduce costs.

Safety and Regulations

When transporting solar panels, you must follow relevant regulations and safety practices. The U.S. Department of Transportation (DOT) has regulations regarding transporting solar panels, including labeling and proper packaging requirements (https://www.epa.gov/hw/solar-panel-frequent-questions). Since solar panels contain potentially hazardous materials like lead and cadmium, special care must be taken to prevent breakage and environmental contamination.

In addition to federal DOT regulations, some states like California and Texas have additional rules for transporting solar panels safely on state highways and roads (https://a1solarstore.com/blog/how-to-transport-ship-carry-and-move-solar-panels-around.html). This includes proper load securing, warning signs, and special driver training. The panels must be properly secured and cushioned during transport. Packing standards like those from the International Electrotechnical Commission can help minimize vibration and impacts (https://www.iec.ch/blog/how-transport-pv-modules-safely-0).

Following these safety practices and regulations protects the panels from damage, prevents hazardous spills, and keeps both the public and transportation workers safe when solar panels are in transit.

Conclusion

Transporting solar panels requires careful planning and preparation. The three main methods each have their benefits and drawbacks.

Truck transport is the most common for domestic shipping. It allows precise delivery times and tracking. However, road hazards and vibrations can damage the panels.

Shipping transport is more cost effective for international deliveries. It takes longer but reduces handling. Size limitations and rough seas can cause issues.

Air transport is the fastest option but also the most expensive. It’s mainly used for small, urgent shipments. Turbulence and improper packaging can damage the panels.

No matter the method, proper packaging is essential. Shock and vibration absorbing materials help protect the panels in transit. Proper permits and oversize load procedures should be followed.

Overall, with careful planning and preparation, solar panels can be safely transported to their destination.