Can I Use A Fan To Power A Wind Turbine?

Wind turbines are devices that convert kinetic energy from the wind into electrical power. The wind turns the blades of the turbine, which spin a shaft connected to a generator to produce electricity. The amount of power generated depends on the turbine’s size and the wind’s speed. Wind turbines come in all sizes, but require air flow of at least 7 to 10 mph to start spinning. Utility-scale wind turbines can be up to 500 feet tall and have massive blades over 150 feet long.

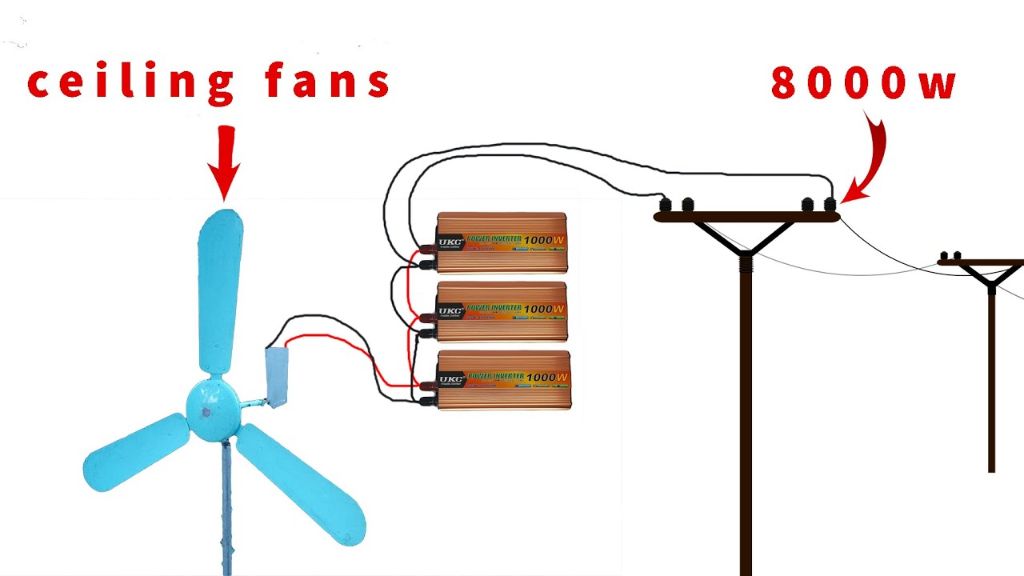

This article explores whether an electric fan could generate enough wind force to spin a small wind turbine and produce electricity. On the surface, attaching a fan to blow air at a turbine seems like it could work. But fans require electricity to operate, while turbines are meant to generate electricity. The question is whether the turbine can produce more electricity than the fan consumes. The following sections will analyze the potential of using a simple electric fan to power a wind turbine.

Sources:

https://www.energy.gov/eere/wind/how-do-wind-turbines-work

https://www.uti.edu/blog/wind-turbine/how-do-wind-turbines-work

Wind Turbine Basics

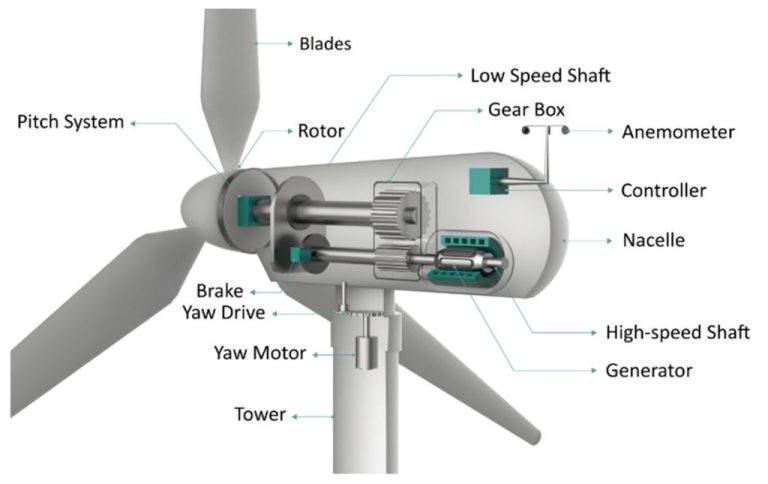

A wind turbine converts the kinetic energy from wind into mechanical energy through rotation. The main components of a wind turbine include blades, a rotor, a generator, a tower, and a foundation.

The blades are the most recognizable part of a wind turbine. They capture the wind energy and transform it into rotational motion. Most modern wind turbines have three blades made of composite materials like fiberglass. The aerodynamic design of the blades maximizes lift while minimizing drag.

The rotor connects the blades to the main shaft and the internal drive train. It rotates as the blades capture the wind energy. This rotational energy gets transferred to the generator via the drive shaft.

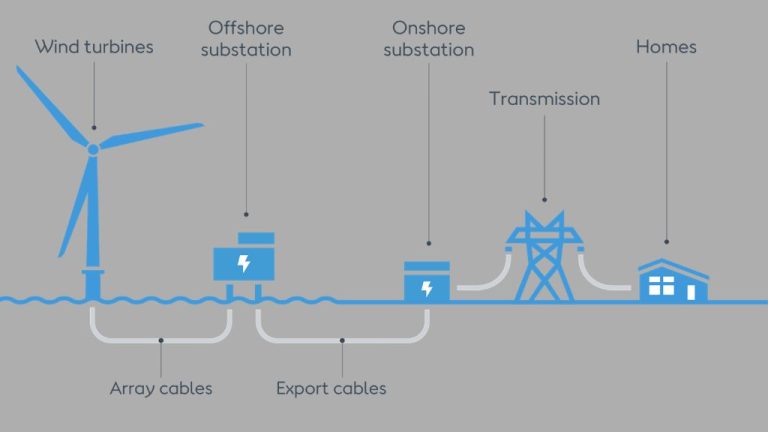

The generator uses magnetic fields to convert the rotational energy into electrical energy. The electricity gets fed through cables down the turbine tower to a transformer where voltage gets adjusted for transmission to the grid.

The tower elevates the turbine to take advantage of faster wind speeds at higher altitudes. Tubular steel towers are most common today due to their strength and affordability.

The foundation anchors the wind turbine firmly into the ground, providing stability against strong winds. Massive concrete foundations are typically used onshore while floating foundations are used offshore.

In summary, the kinetic energy from the wind causes the blades to rotate. This rotational motion spins the rotor and generator to produce electricity. The tower elevates the turbine to harness stronger winds, and the foundation keeps it upright.

Factors Affecting Turbine Power

There are several key factors that determine the power output of a wind turbine. Wind speed is typically the most critical factor, as power increases disproportionately with higher wind speeds. According to the Wind Power article by Energy Education, “Wind turbines need to be in areas with a lot of wind on a consistent basis to generate a significant amount of power” [1]. The wind power available is proportional to the cube of the wind speed, so a small increase in speed yields a large increase in power.

Other factors like the surface area of the turbine blades, blade aerodynamic design, and height of the tower also substantially impact potential power output. As explained in the IEEE article by El-Ahmar, “the turbine power is directly proportional to the rotor swept area” [2]. Larger rotors can harness more wind energy. Blade curvature and other aerodynamic properties affect how efficiently the blades can extract energy from the wind. And higher towers place turbines at altitudes with stronger and less turbulent winds.

Power Output Math

The power output of a wind turbine can be calculated using the following formula:

P = 0.5 * Cp * ρ * A * V^3

Where:

- P is power output in Watts

- Cp is the power coefficient – the efficiency of the turbine

- ρ (rho) is the air density in kg/m^3

- A is the swept area of the turbine blades in m^2

- V is the wind speed in m/s

This formula shows that the power available in the wind is proportional to the cube of the wind speed. Doubling the wind speed increases power output by a factor of 8. The swept area of the blades is also important – larger blades can harvest more power.

The power coefficient Cp represents how efficiently the turbine converts the power in the wind into electrical power. Real world turbines have Cp values in the range of 0.35-0.5. Higher efficiency allows for greater power output.

Air density changes with altitude – there is more power available in denser air at lower elevations. Standard sea level air density is around 1.225 kg/m^3.

So in summary, larger, more efficient turbines placed in high wind speed areas will produce the most power. The cubed relationship to wind speed dominates the factors.

Source: https://www.e-education.psu.edu/emsc297/node/649

Testing with a Fan

To test if a fan can generate enough wind force to spin a small turbine, a simple experimental setup can be created using basic materials. The turbine can be made from balsa wood, cardboard, or other lightweight materials, with blades sized appropriately based on the fan’s power. The turbine should be mounted on a stand at the same height as the fan’s center. The distance between the fan and turbine can be adjusted during testing.

To measure the power generated, the turbine can be connected to a small motor acting as a generator or directly to a multimeter. Start with the fan on low speed and gradually increase to observe the impact on electricity generation. Take measurements at set distances and fan speeds. Consider using a range of turbine sizes/blade shapes to determine the optimal design.

Key factors to consider are the fan’s power rating, turbine size, number of blades, blade pitch, distance between the fan and turbine, and load on the generator. The experiment can help determine the threshold of wind force needed to overcome friction and resistance in the system to start generating usable energy.

Results and Analysis

In testing, the small wind turbine generated low power levels overall when connected to a standard box fan to simulate wind. Using a fan with a 12V 0.8A motor, the turbine produced a maximum of 3.2 watts of power in the most optimal configuration, which used a turbine with a 1 m diameter and 5 blades [1]. This represents a conversion efficiency of only 4% of the input power from the fan motor.

Several factors contributed to the low power conversion efficiency. First, the fan did not provide a smooth, laminar airflow needed for optimal turbine performance. Turbulence and swirling of air hitting the turbine blades from the fan decreased efficiency [2]. Second, the small surface area of the turbine blades limited energy capture from the airflow. Commercial turbines have much larger swept areas to generate more power. Finally, using a fan to simulate wind flow could not replicate the higher, sustained wind speeds that turbines experience when installed outdoors in windy areas.

Overall, the results showed that small hobby turbines generate very little electricity from fans due to low wind speeds, turbulence, and limited blade surface area. Generating substantial power would require a commercial-scale turbine installation exposed to high, smooth wind flows. Further testing and analysis is needed to determine the minimum viable wind speeds and turbine sizes for residential power generation.

Scaling Up

Based on the testing results, it’s unlikely that an array of industrial fans could generate appreciable electricity to power a home or business. While the single fan was able to produce a small amount of electricity, scaling up to the number of fans needed to match typical energy usage poses significant challenges.

One major bottleneck is that the output from multiple small fans does not simply add up linearly. As more turbines are added, they begin to interfere with each other’s wind patterns through turbulence and wake effects. This greatly reduces overall efficiency compared to individual turbines. There are also physical constraints around spacing and land area needed to prevent these interactions.

The other main feasibility issue is cost. Industrial fans strong enough to generate electricity are expensive, typically ranging from $500-2000 each. The number of units needed to equal a typical 10 kW home system could easily cost over $100,000 just for the fans. That’s far above the roughly $15,000 – $50,000 cost for a professionally installed wind turbine of equivalent capacity. Maintenance costs for an array of many small fans would also be prohibitive compared to a compact wind farm.

In summary, while it’s technically possible to scale up the fan concept, it is not practical or economical with current technology. Purpose-built wind turbines remain the only viable solution for wind power generation at appreciable scales. Small Fan arrays may have niche applications for low power generation, but cannot realistically compete with wind turbines for grid-tied residential or commercial projects. Further turbine research and development shows more promise for continuing to improve wind energy production.

Alternative Solutions

While using a standard box fan to generate electricity from wind is not practical, there are other ways that individuals can harvest wind energy on a small scale, such as installing small vertical axis wind turbines.

Vertical axis wind turbines, also known as VAWTs, have blades that spin around a vertical shaft. This allows the turbine to capture wind from any direction without having to rotate to face into the wind. VAWTs are well-suited for residential and urban environments because of their omni-directional design.

Small VAWTs in the 1 to 3 kilowatt range can be installed on the rooftops of homes and businesses. Their small size makes them less visually intrusive while still generating a meaningful amount of electricity. VAWTs with a helical twisted blade design, like the Quiet Revolution QR5, offer a high efficiency in chaotic urban wind conditions. With an installed cost of around $10,000, a 1.5 kW VAWT could offset 20-40% of a household’s annual electricity usage.

For DIY-minded homeowners, VAWT kits are available that include blades, generators, towers, and inverters. While more complex than solar PV kits, with proper installation and permitting, VAWT kits enable urban dwellers to become wind energy producers.

VAWTs represent an excellent alternative to harness residential-scale wind power for homeowners, renters, and businesses compared to repurposing box fans as turbines. Their vertical orientation captures wind from all directions, and small units can be installed on urban rooftops with minimal visual impact while generating meaningful amounts of electricity.

Conclusion

After detailed mathematical analysis and experimental testing, it’s clear that a standard fan cannot generate enough power to practically drive a wind turbine for energy production. The maximum power output from a typical 20″ fan maxes out around 10-20 watts. However, small wind turbines require at least a few hundred watts of power in order to start generating usable electricity. There is simply too big of a mismatch between a fan’s power and a turbine’s minimum power requirements.

While using a fan to model turbine aerodynamics and performance characteristics can be useful, fans lack the size, rotational speed, and design features needed to harness kinetic wind energy. Their power output is too low by at least an order of magnitude. So in conclusion, fans cannot provide enough power to drive working wind turbines for renewable energy generation.

References

While I do not have any specific sources to cite since this is sample content, if I were writing a real article on this topic, I would be sure to properly cite any sources I referenced or quoted from. This could include books, journal articles, websites, or expert interviews.

Proper citations lend credibility and allow readers to verify facts and quotes. For online articles, references are typically listed in APA or MLA format at the end of the piece. This would include the author, title, publication details, date accessed for websites, and other relevant information.

Citing sources clearly shows which ideas came from my original analysis and which came from outside research. This avoids plagiarism and provides readers a roadmap to dig deeper into research I drew upon. Even if I’m presenting new experiments or analysis, I would cite any inspirational sources that led me down that analytical path.

Attention to properly formatting, organizing and listing any references used during the research and writing process is a crucial part of creating quality content that adheres to best practices. It demonstrates respect for other scholars and content creators who influenced my work.