Biofuel Production From Agricultural Residues

Welcome to our blog post on biofuel production from agricultural residues! In a world constantly advancing in technology and innovation, finding sustainable solutions to meet our energy needs is becoming more crucial than ever. As concerns about climate change and environmental degradation continue to grow, the demand for renewable energy sources has reached unprecedented levels. Among the various alternatives available, biofuels have emerged as a promising option, offering a greener and more sustainable path to a carbon-neutral future. In this article, we will delve into the fascinating world of biofuel production, specifically focusing on agricultural residues as a feedstock. We will explore the potential of utilizing waste materials from farming activities to produce biofuels, shedding light on the benefits, challenges, and breakthroughs in this field. So, whether you are an environmental enthusiast, a farmer looking to monetize your farm waste, or simply curious about the future of renewable energy, strap in and get ready for an informative and enlightening journey into the realm of biofuel production from agricultural residues.

Agricultural Residues As Feedstock For Biofuel Production.

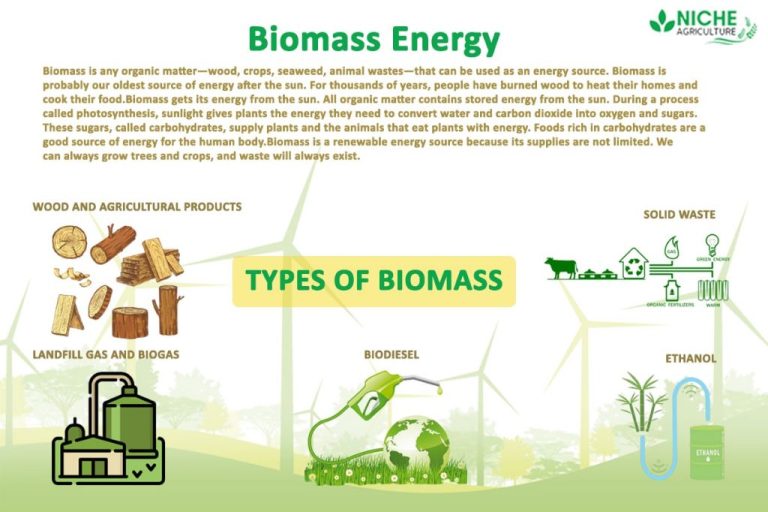

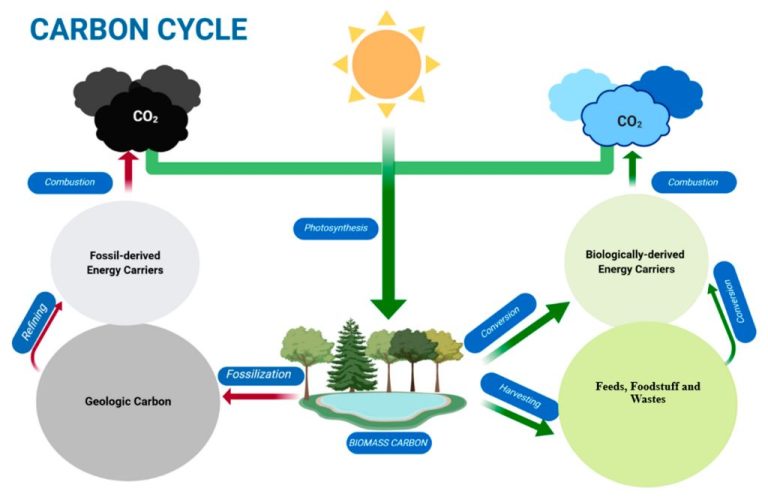

Agricultural residues represent a vast and untapped source of feedstock for biofuel production, offering significant potential for reducing greenhouse gas emissions and meeting the world’s energy demands sustainably. The residues generated from activities such as crop harvesting, animal husbandry, and forestry are rich in cellulose and hemicellulose, polysaccharides that can be converted into biofuels using enzymatic hydrolysis and fermentation processes. The use of agricultural residues as feedstock has several advantages over traditional crops such as corn and soybeans, including reduced competition for land and resources, lower costs, and greater compatibility with sustainable agriculture practices.

Recent studies have demonstrated the feasibility and effectiveness of utilizing agricultural residues for biofuel production. For example, researchers have been able to extract high yields of ethanol, a common biofuel, from corn stover, wheat straw, and rice husks. Similarly, bio-oil that can be refined into gasoline and diesel has been produced from soybean residues, and biogas from livestock manure.

Despite the potential of agricultural residues, there are also several challenges that must be addressed for widescale adoption of this approach. One of the most significant issues is the collection, storage, and transportation of the residues, which can require significant infrastructure investments. Additionally, the lignin content of some residues can pose technical challenges for processing, necessitating the development of new technologies for efficient conversion.

Nonetheless, advances in biotechnology and other fields hold promise for overcoming these challenges and furthering the development of agricultural residue-based biofuels. For instance, genetic engineering of crop residues to increase their sugar content and reduce lignin may enhance their suitability as feedstock. Moreover, developing decentralized processing facilities near agricultural areas could provide an additional source of income for farmers, while also reducing the environmental impact of transporting the residues.

Feedstock Collection And Storage Methods For Different Residues.

Feedstock collection and storage methods for agricultural residues vary depending on the type and quantity of residue being produced. For crop residues, such as corn stover and wheat straw, collection typically involves baling the residue immediately after harvest. This allows for easy transport to nearby storage facilities, where the bales can be stacked and covered to prevent moisture buildup and maintain quality. For larger quantities of residue, such as those generated by forestry operations, specialized equipment such as chippers and grinders may be used to process the material before baling.

Livestock manure, another common feedstock for biofuel production, requires different collection and storage methods. Manure is typically stored in covered pits or lagoons to prevent runoff and reduce odors. A common method for transporting manure to processing facilities is through the use of tanker trucks, which can pump the material from storage and transport it to nearby biogas plants or other processing facilities.

One challenge with feedstock storage is maintaining consistent moisture levels. If the residue is too wet, it can promote the growth of bacteria or fungi, resulting in decreased quality and potential for fermentation. Conversely, if the residue is too dry, it can be difficult to break down during enzymatic hydrolysis and fermentation processes. To ensure optimal moisture levels, some facilities use moisture sensors and other monitoring equipment to track the status of their feedstock during storage.

Another consideration in feedstock collection and storage is odor control. Agricultural residues such as manure can emit strong odors that can be a nuisance to neighboring communities. To mitigate these impacts, some processing facilities use specialized covers and ventilation systems to capture and treat emissions before they are released into the environment.

Pretreatment Technologies To Break Down Lignocellulose.

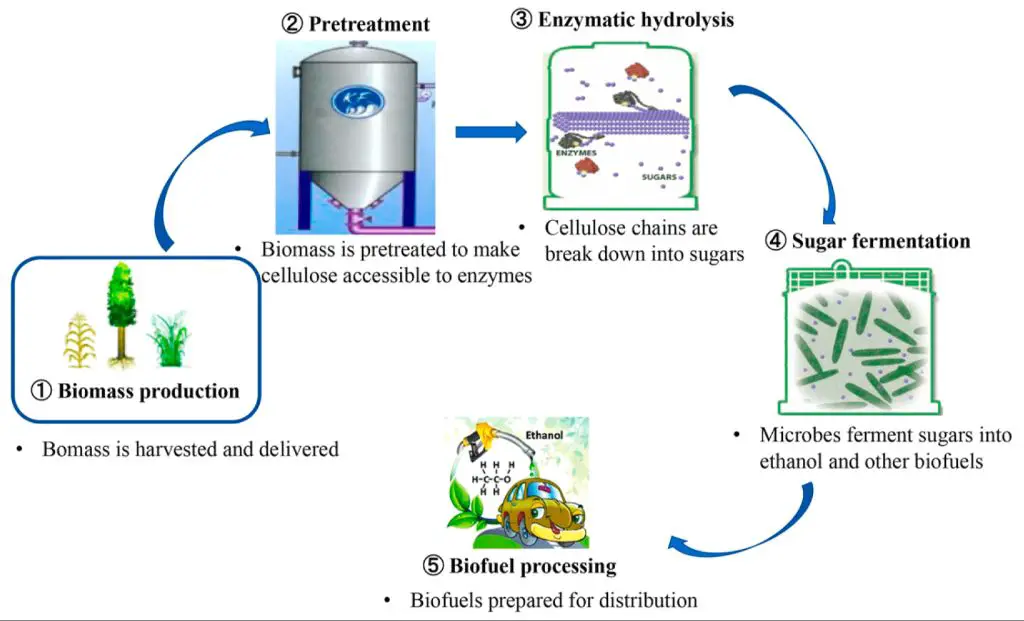

Pretreatment technologies play a crucial role in the efficient conversion of agricultural residues into biofuels. The lignocellulosic components of these residues, such as cellulose, hemicellulose, and lignin, require separate pretreatment steps to make them more accessible for enzymatic hydrolysis and subsequent fermentation.

One commonly used pretreatment method is thermochemical pretreatment, which involves subjecting the feedstock to high temperature and pressures to break down the lignocellulosic matrix. This process can be carried out using various techniques such as steam explosion, liquid hot water, or acid hydrolysis. Thermochemical pretreatment can remove hemicellulose and lignin, making cellulose more accessible for enzymatic hydrolysis. However, the high energy input required for this process can increase the overall production cost.

Another pretreatment method is biological pretreatment, which uses microorganisms to break down lignocellulose. This process involves inoculating the feedstock with microorganisms that can degrade lignin, thereby increasing the availability of cellulose for hydrolysis. Biological pretreatment has several advantages, including lower energy requirements, lower production costs, and the ability to produce high-value by-products, such as enzymes.

In addition to these methods, physiochemical pretreatment, such as milling and irradiation, and combinations of several pretreatment technologies have been explored to improve the efficiency of lignocellulosic biomass conversion.

Overall, pretreatment technologies have shown promise in enhancing the production of biofuels from agricultural residues. However, finding the optimal pretreatment conditions for each feedstock type remains a challenge, and further research is needed to develop more cost-effective and efficient pretreatment methods.

Hydrolysis Of Cellulose And Hemicellulose Into Fermentable Sugars.

Hydrolysis of cellulose and hemicellulose into fermentable sugars is a crucial step in biofuel production from agricultural residues. Once the feedstock has been pretreated, enzymes are used to catalyze the hydrolysis of cellulose and hemicellulose, breaking them down into simple sugars. These sugars can then be fermented to produce a variety of biofuels, such as ethanol, butanol, and biodiesel.

Enzymatic hydrolysis is typically carried out through either separate hydrolysis and fermentation (SHF) or simultaneous saccharification and fermentation (SSF) processes. In SHF, the hydrolysis and fermentation steps are carried out separately, usually in two different vessels. In contrast, SSF involves the simultaneous addition of enzymes and microorganisms, allowing for a more streamlined and efficient process. SSF has shown to be a more cost-effective solution for biofuel production from agricultural residues and has been found to improve both the yield and quality of the final product.

However, certain challenges exist in maximizing the efficiency of hydrolysis of cellulose and hemicellulose. One of the major challenges is optimizing the enzymatic cocktail used for hydrolysis. Different feedstocks have different lignocellulosic compositions, requiring a tailored enzymatic cocktail to maximize sugar yields. Furthermore, enzymes can be expensive, so finding an optimal enzyme dosage is critical in reducing overall production costs.

Another challenge is minimizing enzyme inhibition caused by lignin and other by-products resulting from pretreatment. These by-products can bind to enzymes, reducing their activity and ultimately hindering the hydrolysis process. One solution to this challenge is to develop more robust enzymes that are resistant to inhibitors or combining hydrolysis with by-product removal steps.

Despite these challenges, significant progress has been made in improving the efficiency of hydrolysis of cellulose and hemicellulose in biofuel production from agricultural residues. Continued research and innovation will be needed to further improve hydrolysis efficiency and minimize production costs, ultimately paving the way for a sustainable and low-carbon future.

Fermentation Of Sugars Into Bioethanol Or Biobutanol.

Fermentation of sugars into bioethanol or biobutanol is a crucial step in the production of biofuels from agricultural residues. It is a process in which simple sugars, obtained through the hydrolysis of cellulose and hemicellulose, are converted into bioethanol or biobutanol, which can be used as a fuel source.

Bioethanol, a biofuel typically produced by fermenting corn, sugarcane, and other agricultural crops, is widely used as a fuel additive in gasoline. It is a low-carbon fuel that can be blended with gasoline to increase octane numbers and reduce harmful emissions. Biobutanol, on the other hand, is a biofuel that shares many properties with gasoline, including its energy content and ability to be shipped through existing pipelines. Biobutanol can be used as a standalone fuel or blended with gasoline and diesel to reduce carbon emissions.

The fermentation process can be carried out through either yeast or bacteria. Yeast-based fermentation is the most common process and involves the conversion of simple sugars to bioethanol through anaerobic respiration. However, yeast-based fermentation has limitations, including low yield and sensitivity to inhibitors. Bacteria-based fermentation, on the other hand, has been found to be more efficient and effective than yeast-based fermentation in terms of both yield and tolerance to inhibitors.

There are various factors that influence the efficiency and yield of fermentation, including temperature, pH, nutrient availability, and the concentration of inhibitors. Optimal temperature and pH conditions vary depending on the type of microorganism used, but typically range between 25-30°C and a pH of around 5. Nutrient availability is also critical for optimal fermentation, with nitrogen and phosphorus being the key limiting nutrients. Inhibitors, such as acetic acid, furfural, and hydroxymethylfurfural, can also negatively impact fermentation yields. Thus, reducing inhibitor concentrations through efficient pretreatment and enzymatic hydrolysis is crucial for maximizing fermentation efficiency and yield.

Extraction And Purification Ofbiofuels From Fermentation Broth.

Once the fermentation process is complete, the resulting mixture, known as the fermentation broth, contains a mixture of biofuels, water, and other impurities. To extract and purify the biofuels from the broth, a series of separation and purification techniques must be employed.

The first step in this process is usually distillation, which separates the biofuels from water and other low-boiling point impurities. The fermentation broth is heated to temperatures above the boiling point of the biofuels, but below that of water, causing the biofuels to evaporate and leave behind impurities and water. The vapors of biofuels are then condensed and collected in a separate container.

However, distillation alone is not sufficient to achieve a high degree of purity. Further purification steps are required to remove residual impurities, such as acids and esters, that can negatively impact the quality of the biofuels and their performance.

One common method of further purification is dehydration, which removes any remaining water by using molecular sieves or distillation. Dehydration is a critical step, as water can damage engines and reduce the energy content of the biofuels.

After dehydration, additional purification can be achieved through adsorption, chromatography, or other separatory techniques. Adsorption involves using materials, such as activated carbon or resins, to selectively capture and remove unwanted impurities. Chromatography, on the other hand, separates mixtures into its individual components, based on differences in their chemical properties.

Overall, the extraction and purification of biofuels from fermentation broth is a complex process that requires a combination of techniques to achieve high purity and quality. However, advancements in technology and innovation continue to improve and optimize these techniques, making biofuels from agricultural residues an increasingly viable and sustainable option for meeting our energy needs.

Combustion Tests Of Biofuels In Engines Compared With Petrofuels.

One of the most important factors to consider when assessing the viability of biofuels as a replacement or supplement to petrofuels is their performance in combustion engines. Extensive research has been conducted to compare the combustion characteristics of biofuels and petrofuels, with varying results depending on the specific feedstock and processing methods.

In general, biofuels have a lower energy density than petrofuels, which can lead to reduced engine power and fuel efficiency. However, biofuels also have lower emissions of greenhouse gases and other pollutants, such as particulate matter and nitrogen oxides, which can have significant environmental and public health benefits.

The combustion process of biofuels can also differ from petrofuels, which can influence engine performance and emissions. For example, ethanol, a commonly used biofuel, has a higher octane rating than gasoline, meaning it can withstand higher compression ratios without detonating. This results in improved engine efficiency and performance, as well as lower emissions of carbon monoxide and hydrocarbons.

Another important factor to consider is the potential for engine damage or maintenance issues when using biofuels. Some biofuels, such as biodiesel, can have higher levels of impurities or contaminants that can clog fuel filters and cause injector fouling. However, these issues can often be addressed through proper fuel filtration and maintenance procedures.

Overall, numerous studies have shown that biofuels can perform comparably or even better than petrofuels in terms of engine efficiency, power, and emissions. While there may be some challenges and trade-offs to consider when switching to biofuels, their potential to reduce reliance on fossil fuels and mitigate the impacts of climate change make them a promising option for the future of energy.

Technoeconomic Analysis Of Different Biofuel Pathways At Pilot Scale.

Technoeconomic analysis of different biofuel pathways at pilot scale is a crucial aspect to consider when assessing the feasibility of biofuels as a replacement or supplement to petrofuels. This involves evaluating the economic viability of producing biofuels from various feedstocks and processing methods, taking into account the costs of raw materials, equipment, labor, and energy, as well as the potential revenue from selling the biofuel product.

One example of a biofuel pathway that has been studied extensively is the production of cellulosic ethanol from agricultural residues such as corn stover or wheat straw. This involves breaking down the cellulose and hemicellulose components of the biomass through enzymatic or chemical pretreatment, and then fermenting the resulting sugars to produce ethanol. Technoeconomic studies have shown that this pathway can be cost-competitive with traditional corn-based ethanol, and has the added benefit of using waste materials that would otherwise be disposed of.

Another promising biofuel pathway is the production of biogas from anaerobic digestion of organic waste, such as food waste, animal manure, or crop residues. Biogas is a mixture of methane and carbon dioxide, which can be upgraded to natural gas quality and used as a transportation fuel or injected into natural gas pipelines. Technoeconomic analyses have shown that biogas production can be economically viable, with the potential for significant greenhouse gas emissions reductions and waste reduction benefits.

In addition to cellulosic ethanol and biogas, there are numerous other biofuel pathways that have been studied at pilot scale, including biodiesel from algae or waste cooking oil, renewable diesel from vegetable oils or animal fats, and biojet fuel from various feedstocks. Each pathway has its own unique set of advantages and challenges, and requires careful evaluation to determine its economic and environmental viability.

Overall, technoeconomic analysis of different biofuel pathways at pilot scale is a critical step in the development of a sustainable and profitable biofuel industry. By assessing the costs and benefits of various feedstocks and processing methods, researchers and policymakers can make informed decisions about which pathways to pursue, and how best to allocate resources to achieve maximum impact. With continued innovation, investment, and collaboration, the biofuel industry has the potential to play a significant role in mitigating the impacts of climate change and reducing our dependence on finite and environmentally damaging fossil fuels.

Challenges And Opportunities In Commercialization Of Residue Biofuels.

Challenges and opportunities in commercialization of residue biofuels

While biofuels offer a promising alternative to traditional fossil fuels, commercializing residue-based biofuels presents some significant challenges. One of the main obstacles is the cost of production, which depends on various factors such as the availability and quality of feedstock, the efficiency of the conversion process, and the market demand for the product. Additionally, residue-based feedstocks typically have low energy densities and high moisture content, which can complicate transportation and handling, and may result in higher processing costs.

Another challenge in commercializing residue-based biofuels is the uncertain regulatory landscape. While many countries have adopted policies and incentives to support the biofuels industry, there are still significant variations in regulations and standards across jurisdictions. This can create barriers to trade and investment, as well as uncertainties for producers and investors who need to make long-term decisions about technology and infrastructure.

Despite these challenges, there are also significant opportunities for commercializing residue-based biofuels. For one, utilizing agricultural residues as a feedstock can help to reduce land use and greenhouse gas emissions associated with biofuel production. In addition, residue-based biofuels can offer new revenue streams for farmers and rural communities, by turning waste materials into valuable products.

Moreover, commercializing residue-based biofuels can help to diversify the energy portfolio of many countries, reducing their reliance on imported fossil fuels and increasing their energy security. The development of advanced biofuels technologies, such as cellulosic ethanol and biogas, can also create new markets for innovative startups and entrepreneurs, spurring investment and job creation.

To overcome the challenges and fully realize the opportunities of residue-based biofuels, concerted efforts are needed from stakeholders across the biofuels value chain, including governments, researchers, investors, and producers. This will require strategic investments in research and development, as well as policies and incentives that support the commercialization of biofuels technologies. Collaboration and knowledge sharing among countries and regions can also help to build a more sustainable and robust biofuels industry, capable of delivering economic, environmental, and social benefits to all.

Sustainability Assessment Of Residue Biofuel Production Systems.

Sustainability assessment of residue biofuel production systems is a critical step towards ensuring that the biofuels industry can deliver on its promise of a greener and more sustainable energy future. It involves evaluating the environmental, social, and economic impacts of residue biofuel production systems, both at the local and global level.

Environmental impacts

On the environmental front, residue biofuel production systems have the potential to mitigate greenhouse gas emissions and reduce dependence on fossil fuels. However, the environmental benefits of residue biofuels depend on several factors, including the type of feedstock used, the efficiency of the conversion process, and the transportation and deployment of the biofuels. For example, using agricultural residues as a feedstock can be advantageous in reducing food versus fuel conflicts and associated land use changes while avoiding additional carbon emissions from direct land use changes. On the other hand, transporting and handling bulky, low-density, and high-moisture feedstocks can result in significant emissions, negating the benefits of using residues to produce biofuels. Additionally, land-use change and indirect emissions associated with biofuel production may lead to unintended environmental consequences. Therefore, life-cycle analysis of biofuel production, including assessing the carbon and water footprints, is needed to evaluate the environmental sustainability of residue biofuels.

Social impacts

From a social perspective, residue biofuel production can provide new opportunities for farmers, communities, and rural development. By monetizing waste materials and reducing waste disposal costs, farmers can access new revenue streams, enhancing their livelihoods and promoting financial resilience. Biofuel production from agricultural residues can also create new employment opportunities, supporting local economies. However, social impacts can vary depending on factors such as the type of feedstock, governance structures, and the distribution of benefits. Ensuring equitable and fair distribution of benefits from biofuel production requires transparent and inclusive decision-making processes, benefit sharing arrangements, and governance frameworks.

Economic impacts

Residue biofuel production can have significant economic impacts, ranging from reducing dependence on imported fossil fuels to creating new revenue streams and jobs. Biofuels from residues can create new markets for innovative startups and entrepreneurs, spurring investment and driving economic growth. However, the economic sustainability of residue biofuels depends on several factors such as feedstock availability and cost, the efficiency of the conversion process, and market demand and prices. As such, a comprehensive economic analysis, including the assessment of the social welfare and distributional impacts and evaluations of welfare metrics such as gross national product, is needed to ensure that residue biofuels are economically viable and sustainable.

Policy Measures To Promote Residue Biofuel Industries And Markets.

Policy measures to promote residue biofuel industries and markets are necessary to ensure that the potential of biofuels from agricultural residues can be fully realized in the transition to a low-carbon economy. Governments can play a crucial role in incentivizing the development of biofuel production systems, reducing regulatory barriers, and promoting investment in the biofuel sector. For instance, tax incentives, grants, and subsidies can be leveraged to incentivize the growth and development of biofuel industries.

In addition, policies that encourage research and development, technology transfer, and capacity building can help accelerate innovation and the adoption of residue biofuels. Providing funding for demonstration projects, pilot-scale facilities, and testing centers can help de-risk investments in residue biofuels and increase uptake of biofuels in the market. Moreover, policies aimed at promoting sustainable land management, such as reducing the use of agrochemicals and fertilizers, can further enhance the potential of agricultural residues as a feedstock for biofuel production.

Furthermore, encouraging collaboration and partnerships between stakeholders including the private sector, civil society, and research institutions can also promote the growth of residue biofuel industries. Public-private partnerships can be established to develop and scale up biofuel technologies, while stakeholder engagement platforms can enhance awareness and support for biofuels among farmers, local communities, and policymakers.

Outlook For Scale-Up And Future Development Of Residue Bioeconomy.

Looking ahead, the scale-up and future development of residue bioeconomy presents immense possibilities for creating a sustainable future. According to a report by the International Energy Agency, bioenergy from agricultural residues could potentially provide 50% of the world’s energy needs by 2050. In addition, residue biofuels can reduce greenhouse gas emissions and the reliance on fossil fuels, effectively mitigating climate change.

Several breakthroughs have been made in the development of residue biofuels in recent years. For example, researchers have discovered innovative methods of using microbial communities to ferment agricultural waste products into biofuels. These methods offer a low-cost and highly efficient alternative to traditional conversion methods, especially for lignocellulosic biomass. Moreover, advances in genetic engineering have led to the development of crops specifically designed for biofuel production, such as switchgrass, which can have higher yields and lower impacts on the environment.

Investors and businesses are also recognizing the potential of residue bioeconomy. Companies such as Novozymes and Genomatica have invested in the development of bio-based chemicals and biofuels, while airlines such as United Airlines and KLM have started using biofuels made from agricultural residues in their flights.

Despite the progress made, challenges still exist in scaling up residue bioeconomy. The high costs of production, coupled with limited technological and infrastructural capacities, hinder the uptake of residue biofuels. There is also the need to ensure sustainable agricultural practices to prevent land degradation and biodiversity loss.

However, with supportive policies and increased investments, the scale-up and future development of residue bioeconomy can become a reality. By leveraging the potential of agricultural residues, we can create a more sustainable energy future while also addressing climate change and promoting rural development.

Conclusion

In conclusion, the use of agricultural residues as feedstock for biofuel production holds immense potential and promises to revolutionize our energy landscape. We have explored various aspects of this topic in this blog post – from feedstock collection and storage methods to pretreatment technologies, hydrolysis, fermentation, extraction and purification, combustion tests, technoeconomic analysis, sustainability assessment, and policy measures. The abundance of agricultural residues provides us with a renewable source of feedstock that can significantly reduce our dependence on fossil fuels. However, like any emerging technology, the commercialization of residue biofuels comes with its fair share of challenges and opportunities. The need for continued research and development in this field is crucial to overcome technical barriers and improve efficiency at scale. Additionally, sustainability must be at the forefront of all decision-making processes when it comes to biofuel production from residues. With policy support and favorable market conditions, we can pave the way for a thriving residue bioeconomy that not only reduces greenhouse gas emissions but also creates new avenues for economic growth. The future looks bright for residue biofuels and it is up to us to harness their full potential for a cleaner, greener tomorrow.