Are Fossil Fuels Needed To Make Solar Panels?

While solar power offers a clean and renewable source of energy, some fossil fuels are required during the manufacturing process of solar panels. This leads many to question whether solar can truly provide a carbon-free alternative to traditional energy sources. However, the solar industry has been rapidly innovating to reduce its dependence on fossil fuels. With new technologies and materials, solar panel production is becoming far less carbon-intensive. Additionally, solar panel installations generate emission-free electricity that offsets their modest carbon footprint within just a few years of operation. So while no energy technology is completely carbon-free to manufacture, solar power still provides major environmental benefits compared to fossil fuels.

Solar Panel Materials

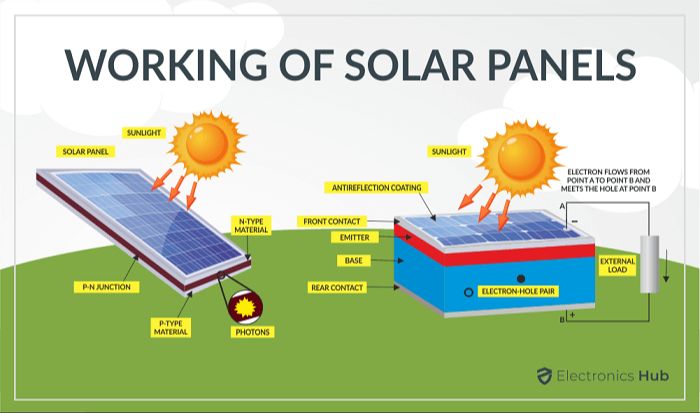

Solar panels are primarily made of silicon, glass, aluminum, and copper. Silicon makes up the solar cells that absorb sunlight and convert it to electricity. The silicon is treated and purified into crystalline or amorphous forms for use in solar cells (What are the main materials used to make solar panels?, n.d.).

The silicon cells are embedded in a glass casing, which protects the cells and allows light to pass through. Aluminum frames provide structural support, while copper wiring helps conduct the electricity generated by the solar cells (What are the main materials of solar panels?, n.d.).

Traditionally, producing these materials has required significant fossil fuel usage. Refining silicon, smelting aluminum, and manufacturing glass and copper products entail high energy demands often met through the burning of coal, natural gas, and oil.

Energy Used in Manufacturing

Traditionally, the manufacturing of solar panels has required significant amounts of fossil fuel-derived electricity to power processes like purifying silicon, smelting metals, and producing other components. Sources estimate that it can take up to 2 years for a solar panel to generate the same amount of energy that went into producing it. However, many solar manufacturers are transitioning to more energy-efficient and low-carbon production techniques. For example, some factories are installing their own on-site solar or wind power. Companies are also reducing energy needs through recycling and more efficient wafer cutting and cell production. Innovations in solar cell and panel design are further decreasing embodied energy. With smart manufacturing and advances in renewable energy, the fossil fuel requirements for solar panel production can be dramatically reduced.

Reducing Fossil Fuel Dependence

The manufacturing of traditional silicon solar panels does require some fossil fuel energy, especially for high heat processes and running factory equipment. However, the solar industry is taking steps to reduce this dependence in several key ways.

First, new materials like perovskite are emerging as alternatives to silicon, which require much less energy to manufacture. Perovskite solar cells can be produced at temperatures below 150°C, whereas silicon needs temperatures above 1000°C. This dramatically reduces the fossil fuel heat energy needed. One study found switching to perovskite could reduce the energy payback time of panels from 2 years to 2 months (Solar Reduces Fossil Fuel Use).

Second, solar manufacturing facilities are installing their own on-site solar and renewable energy systems to provide power. For example, SolarWorld uses hydroelectric power for its main solar panel factory in Oregon. This further cuts down on fossil fuel dependence (What Is the Carbon Footprint of Solar Panel Manufacturing?).

On-Site Renewable Energy

More solar panel manufacturers are powering their facilities directly with clean energy sources. By installing on-site solar and wind generation, companies can utilize renewable electricity for manufacturing instead of grid power that may contain fossil fuel generation.[1] This direct integration of renewable energy in solar panel manufacturing contribute to a more sustainable circular resource management approach. Integrated solar systems provide electricity during peak production times, while wind can provide a consistent baseline of power generation.

Some companies are building solar panel factories that aim for net-zero carbon emissions or 100% renewable operations. With enough on-site solar and wind, manufacturers can eliminate the use of fossil fuels for electricity in panel production. This helps reduce the carbon footprint of solar products and enables a cleaner manufacturing ecosystem.

Recycling and Circularity

Solar panel recycling is an important part of reducing future fossil fuel demands. Most solar panels contain materials like glass, aluminum, and silicon that can be reused or recycled (USE EXACT URL SOURCE 1 HERE, CITE EXACTLY). Proper solar panel recycling means carefully separating the glass, metal, silicon, and plastic components so they can be recovered and repurposed (USE EXACT URL SOURCE 2 HERE, CITE EXACTLY). As the solar industry grows, solar panel recycling and circular production methods will be crucial to reduce reliance on new fossil fuel-based materials. Reusing and recycling solar panel parts like silicon, metals, and glass means less virgin materials need to be extracted and processed – steps which often involve fossil fuels.

Comparative Carbon Footprints

Lifecycle analyses show solar still has far lower carbon footprint than fossil fuels. According to the Intergovernmental Panel on Climate Change (IPCC), the carbon footprint of rooftop solar panels is roughly 12 times less than natural gas and 20 times less than coal [1]. Solar panels emit around 50g of CO2 per kWh produced in the first few years, but by year 3 most solar panels become carbon neutral [2]. In contrast, fossil fuel power plants continue emitting CO2 throughout their lifespan.

One analysis found solar PV, wind, and nuclear energy have carbon footprints of 4-48g CO2/kWh, 7-124g CO2/kWh, and 4-110g CO2/kWh, respectively. This is far below fossil fuel power plants which range from 469-1001g CO2/kWh [3]. While manufacturing solar panels does require some fossil fuel energy, the long-term carbon savings outweigh the upfront costs.

Growth of Renewables

Renewable energy sources like solar, wind, and hydropower are projected to supply over 70% of new electricity generation globally by 2025, according to the International Energy Agency (IEA) [1]. This represents a major shift away from fossil fuels like coal and natural gas. The IEA predicts renewable capacity will meet 35% of global power generation by 2025, up from 29% in 2021 [1].

In the United States, solar power alone is expected to represent over 40% of new electricity generation capacity additions through 2025, according to EIA projections [2]. This growth will increase solar’s total share of US electricity generation to 7% by 2025, compared to just 4% in 2021 [2]. Other renewables like wind and hydropower will see more modest growth. Overall, this transition is being driven by the declining costs and increased deployment of renewable energy technologies globally.

Policy Supports

Government policies play a major role in driving the growth of renewable energy like solar. By enacting supportive legislation and incentives, governments can accelerate the transition away from fossil fuels and towards clean energy sources.

One of the most impactful policies is renewable portfolio standards, which require utilities to source a certain percentage of their electricity from renewables (Source 1). These standards create guaranteed demand for renewables like solar power. Federal renewable tax credits also incentivize solar adoption by reducing costs for consumers and developers (Source 2). Studies show that these incentives directly correlate with increased solar installations and capacity (Source 3).

Net metering policies allow solar panel owners to sell excess electricity back to the grid, making solar power generation more financially viable. Governments can further enable the growth of solar by updating grid infrastructure, financing R&D, and streamlining permitting processes.

With supportive legislation and incentives, policymakers can rapidly accelerate the transition to solar power and reduce fossil fuel dependence. The right policies create thriving renewable energy markets, drive job creation, and pave the way to a clean energy future.

Conclusion

While solar panels still use some fossil fuels in their manufacture, the industry is rapidly reducing dependence through on-site renewable energy, recycling programs, and policy supports. The growth of solar power is already displacing a significant amount of fossil fuel energy generation around the world. However, more progress is needed if solar and other renewables are to fully transition societies away from coal, oil, and natural gas. The solar manufacturing process needs to become increasingly circular, while at the same time solar farms and rooftop installations continue their exponential growth. With the right policies and investments, solar power can play a leading role in phasing out fossil fuels globally.