हाइड्रो पावर प्लांट कैसे काम करता है?

Hydroelectric power or hydropower is the process of generating electricity by harnessing the power of flowing or falling water. It is one of the oldest and most widely used renewable sources of energy. The history of hydropower goes back to the late 19th century, with the first hydroelectric power plants being built in the 1880s in the United States and Europe.

Some key advantages of hydroelectric power include:

- Renewable and sustainable – Hydropower relies on the water cycle and is not depleted like fossil fuels.

- Low operating costs – Once a dam and power plant is built, electricity can be generated for decades at a lower long-term cost than fossil fuels.

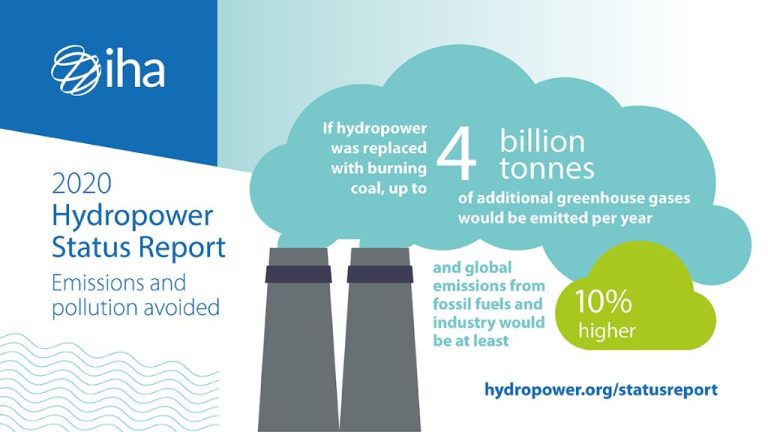

- Clean energy – It does not produce air pollution or greenhouse gases.

- Energy storage – Water can be held in reservoirs and released when electricity demand is high.

- Flood control – Dams can be used to control flooding downstream.

Hydropower Basics

Hydropower plants convert the potential energy of water into kinetic energy to generate electricity. They utilize the natural water cycle where water is stored in dams or reservoirs at higher elevations. When the water is released, it flows through tunnels and shafts called penstocks. The moving water rotates turbines coupled to electrical generators to produce electricity. The height of the water’s source and water volume determine the amount of electricity generated. Overall, hydropower provides a clean, renewable energy source by utilizing the water cycle’s innate potential energy.

https://www.energy.gov/eere/water/how-hydropower-works

Major Components

Hydroelectric power plants have several major components that work together to generate electricity:

Dams

Dams are structures built across rivers to impound water and create reservoirs. The water pressure created by dams drives water through penstocks inside the dam to turn turbines. Dams provide a controlled release of stored water for electricity production (U.S. Department of Energy).

Reservoirs

Reservoirs are bodies of water created by dams that store potential energy. The larger and deeper the reservoir, the more potential energy it can store. Reservoirs ensure a steady supply of water to turbines even during times of low natural streamflow (U.S. Department of Energy).

Penstocks

Penstocks are pipes that carry water from the reservoir through the dam to the turbines. The downward slope and narrowing diameter of penstocks increase the velocity of water flowing to the turbines (Bureau of Reclamation).

Turbines

Hydropower turbines convert the kinetic energy of falling water into mechanical energy to spin rotors. Common types are Kaplan, Francis and Pelton turbines. The specific type used depends on the quantity and pressure of the water (U.S. Energy Information Administration).

Generators

Hydropower generators convert the mechanical energy from turbine rotation into electrical energy. The spinning rotors inside generators create a magnetic field that interacts with coils to induce a voltage difference and generate electricity (U.S. Department of Energy).

Dams

Dams are one of the main components of hydropower plants. They serve two primary functions:

Storing potential energy – Dams act as a battery, storing energy in the form of water in their reservoirs. The higher and larger the reservoir, the more potential energy can be stored. According to Wikipedia, India has over 5,334 dams for generating hydroelectricity and irrigation.

Controlling water flow – Dams control the flow of water by regulating the amount released from the reservoir. The controlled release allows optimal water flow through the turbines at the dam’s base to generate electricity. Dams in India like the Tehri Dam provide regulated water flow for electricity generation during dry seasons.

There are several types of dams used in hydropower plants:

- Arch dams – Curved dams that transfer water pressure onto the abutments.

- Gravity dams – Use their weight and shape to resist the water pressure.

- Buttress dams – Have supports on the downstream side to increase stability.

- Embankment dams – Made from earth or rock fill that resist the water pressure.

Dams are a critical component in hydropower plants as they store potential energy and control water flow to the turbines for generating electricity.

Reservoirs

Reservoirs are bodies of water that store water for later use in hydroelectric power generation. They serve as a water supply that can be controlled and managed. Reservoirs can be created artificially with dams or may be naturally occurring lakes.[1]

Some of the largest reservoirs in India that store water for hydroelectric facilities include:[2]

- Rihand Reservoir in Uttar Pradesh – Stores water from the Rihand River behind the Rihand Dam. It has a gross storage capacity of 934.45 million cubic meters.

- Idukki Reservoir in Kerala – Created by the Idukki Dam across the Periyar River. It has a gross storage capacity of 775 million cubic meters.

- Tehri Reservoir in Uttarakhand – Formed by the Tehri Dam on the Bhagirathi River. It has a storage capacity of 2,610 million cubic meters.

Having large reservoirs with adequate water storage capacity is crucial for hydropower generation during drier months when river flows decline.

Penstocks

Penstocks carry water from the reservoir to the turbines in a hydropower plant. They are large pipes made of steel or concrete that transport water at high pressures. The length and diameter of penstocks can vary greatly depending on the terrain and layout of the hydropower plant.

According to research, penstock pipes typically range from 10 feet to 33 feet in diameter. The diameter is designed to maintain optimal water velocity and pressure as it flows downward from the reservoir to the turbines. Too slow of a flow speed causes sediment to settle in the penstock, while too high of a speed causes excess turbulence and pressure issues.

The pipes must withstand immense water pressure, especially at lower elevations. Thicker steel and reinforced concrete are used to construct penstocks to prevent ruptures. Proper supports and anchors are also critical to handle the stress and weight of water-filled pipes traversing down steep inclines.

In addition to transporting water downstream, penstocks also control water flow and pressure into the turbine inlet. Control gates and valves on the upper segments regulate discharge rates to match power generation demands. The flow rate can be changed quickly in response to the electric grid’s load requirements.

Overall, penstocks are a critical component in hydropower plants. Their large diameter pipes carry water from reservoirs to turbines under high pressure conditions. Careful engineering of their diameter, thickness, supports and flow control gates are needed for safe and optimal power generation.

Sources:

Research on standard penstock diameter

Research on calculating penstock diameter

Turbines

Turbines are a critical component of hydroelectric power plants. They convert the kinetic energy of falling water into mechanical energy to run a generator and produce electricity. There are three main types of hydro turbines used in hydropower plants: Pelton, Francis, and Kaplan turbines.

Pelton turbines consist of a wheel with split buckets or cups mounted on the periphery. A high-velocity jet of water strikes each bucket and causes the wheel to turn. Pelton turbines are impulse turbines suitable for high head sites with large water flow. They can operate with heads ranging from 50 to 1,800 meters. Some major manufacturers of Pelton turbines in India include Bharat Heavy Electricals Ltd and Toshiba JSW Turbine and Generator Pvt Ltd.

Francis turbines are reaction turbines that operate with heads ranging from 10 to 750 meters. They consist of fixed vanes that direct water tangentially to the turbine runner, causing it to spin. Francis turbines are the most common type used in hydropower plants globally. Major global manufacturers include GE, Voith, Andritz, and Dongfang.

Kaplan turbines are propeller-type reaction turbines suitable for relatively low head hydropower sites from 2 to 70 meters. They have adjustable blades that can change their pitch to maintain optimal angle to the water flow. Kaplan turbines are widely used in run-of-river hydropower projects. Leading manufacturers in India include BHEL, Voith, and Tata Power.

Generators

The generators in hydroelectric plants convert mechanical energy from the spinning turbines into electrical energy based on electromagnetic induction principles.[1] In electromagnetic induction, a magnetic field is generated when an electrical conductor moves rapidly through a magnetic field. This is the operating principle behind electrical generators.

In hydroelectric generators, the source of mechanical energy is the spinning turbine shaft. The turbine spins conductor coils (made of copper wire) within the strong magnetic field produced by electromagnets inside the generator. This induces a voltage and current within the conductor coils. The alternating current (AC) electricity generated is sent through transformers to increase the voltage before transmitting it over long distances on transmission lines.

Hydroelectric generators produce billions of kilowatt-hours of clean renewable electricity around the world each year. Large hydroelectric generators can be incredibly powerful and efficient. For example, the generators at the Three Gorges Dam in China have a combined capacity of 22,500 megawatts, supplying up to 100 billion kWh of electricity per year.[2]

Transmission

High voltage lines carry power from the hydroelectric plant to electrical grids, where the power can be distributed for consumer and commercial use. Step-up transformers are used to increase the voltage from the generator to high voltage for efficient transmission over long distances via transmission lines.

According to the IEEE article “Hydropower in India: An Update” https://www.orfonline.org/expert-speak/hydropower-in-india-an-update/, hydroelectric power is typically generated at 11-25kV but boosted to 400kV or more for transmission via the grid. The step-up transformers play a crucial role in minimizing transmission losses over hundreds of kilometers.

Environmental Impact

Hydropower projects can have significant impacts on the environment and local ecosystems. One major impact is that dams and reservoirs disrupt natural water flows, which can harm wildlife populations that depend on certain water conditions and access to upstream habitat for spawning. For example, research shows that nearly 90% of Indian Himalayan valleys would be affected by dam building, with 27% of these dams affecting dense forests.[1]

Additionally, reservoirs created by dams emit methane, a potent greenhouse gas, as vegetation decomposes underwater. However, hydropower emits much lower lifecycle greenhouse gas emissions compared to fossil fuels.[2] There are also concerns that India’s push for new hydropower projects could negatively impact biodiversity more than the clean energy benefits justify.[3]

At the same time, hydropower delivers renewable energy without air pollution, supporting biodiversity by avoiding some impacts of climate change and fossil fuel energy. Overall, careful planning and mitigation strategies are needed to minimize ecosystem disruption from hydropower development.